Chemistry has limitless possibilities.

We use chemistry to make the impossible possible and offer unprecedented solutions to the world.

About Us

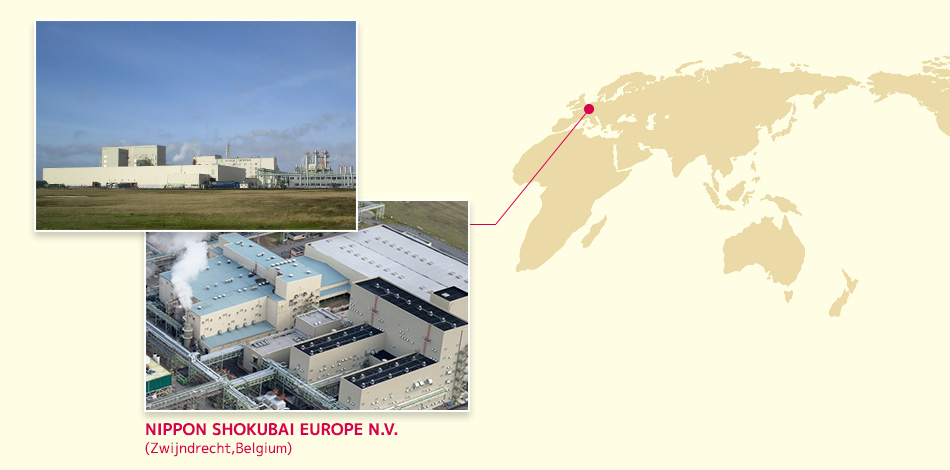

Since 1999, NIPPON SHOKUBAI EUROPE N.V. (NSE) established as subsidiary of NIPPON SHOKUBAI CO., LTD, in Antwerpen, Belgium, We have supplied superabsorbent polymer by one-stop production from raw material acrylic acid on site. Among all, NIPPON SHOKUBAI group's global market share of superabsorbent polymer comes up to No.1, now NIPPON SHOKUBAI EUROPE N.V is a part of NIPPON SHOKUBAI a global chemical company group with its corporate mission as "TechnoAmenity - Providing prosperity and comfort to people and society, with our unique technology."

Company Outline

- Name

- NIPPON SHOKUBAI EUROPE N.V. (NSE)

- Established

- 1999

- Number of employees

- 189 (As of September 30, 2020)

- Business establishments

-

Haven 1053, Nieuwe Weg 1, B-2070, Zwijndrecht, Belgium

TEL +32 (0) 3 250 37 05 - President

- Tomoaki Suzuki

- Organization

-

- Board of Directors

- President

- Manufacturing

- Finance & Accounting

- Sales & Marketing

History

| 1999 | Established NIPPON SHOKUBAI EUROPE N.V. in Antwerpen, Belgium |

|---|---|

| 2001 | Started commercial production of Superabsorbent polymer |

| 2002 | Transferred of business right of ULTRASORB Chemikalien GmbH (established in 1990) |

| 2006 | Expanded superabsorbent polymers plant |

| 2018 | Started commercial production of Acrylic Acid Expanded superabsorbent polymers plant |

Location

Our Products

-

AQUALIC™ CA

Superabsorbent polymers

Diapers, Sanitary products, Industrial products

Our Solutions for a Green and a Connected Europe

Solution - 1 : Solutions to boost battery performance and battery life

- IONEL™ LF-101

- IONEL™ is a patented high purity Lithium bis(fluorosulfonyl)imide "LiFSI".

Can be applied for Lithium-ion batteries. Applicable for electric vehicles and also stationary energy storage.

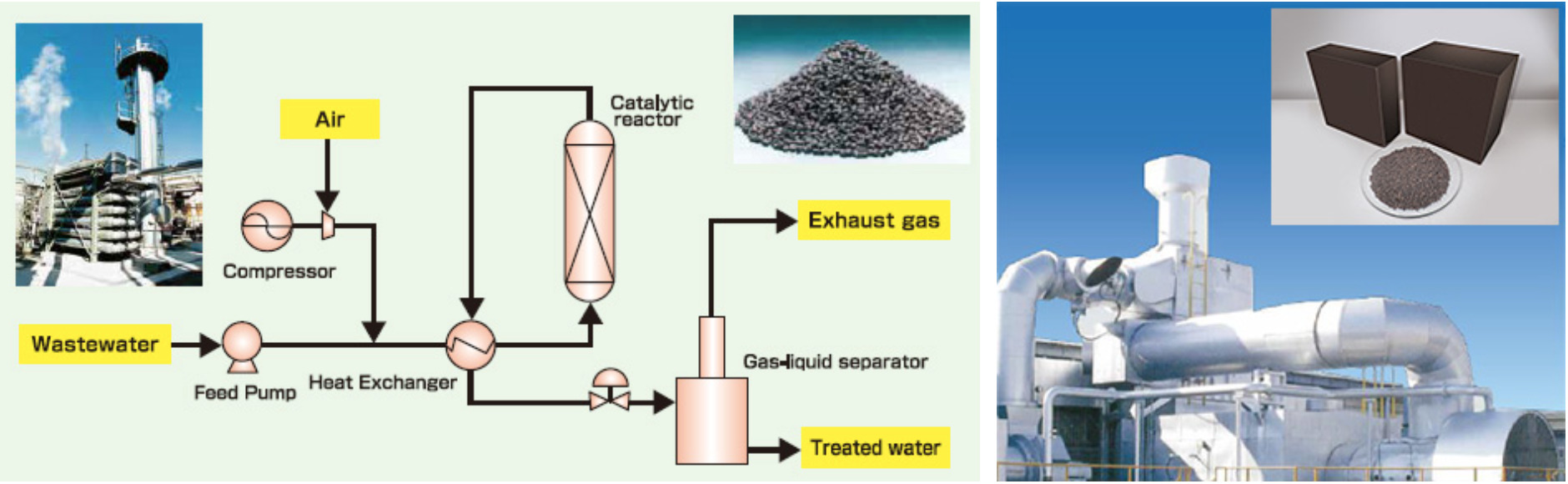

Solution - 2 : Reduction of Greenhouse Gas Emission in the Process Industry

- Wastewater Treatment Catalyst

- Some wastewaters contain poisonous or highly concentrated substances and they are difficult to handle with conventional treatment methods.

Catalytic wet air oxidation technology (CWAO) can decompose these substances into inert gases and simple molecules; Deodorization and decolorization are also possible.

CWAO can be operated without auxiliary fuel by reusing the energy from the oxidation reaction, and thus can replace the conventional wastewater incineration method, resulting in less CO2 emission. - Hydrocarbon Oxidation Catalyst

- This catalyst oxidizes Hydrocarbons (and other Volatile Organic Compounds) in emission gases from various industrial processes.

The energy generated from this reaction can be reused in this process, thus auxiliary fuel is not necessary; Carbon Footprint can be reduced due to less CO2 emission compared to conventional combustion method.

> Air Quality Index Improvement

- Nitrogen Oxide Removal Catalyst

- This catalyst is effective for the reduction of NOx which is one of the important factors of Air Quality Index.

Using ammonia as a reducing agent, converts NOx contained in emission gas into harmless nitrogen.

Our catalyst is widely used in various combustion systems such as boilers, power stations and heating furnaces.

Major features are high performance, low SO2 oxidation rate and high durability for dust.

Solution - 3 : Reliable Subsea Power and Data Connections

Salt-tolerant water-absorbing polymers: AQUALIC™ CS

| Product | Salt-tolerant water-absorbing polymers: AQUALIC™ CS |

|---|---|

| Common Names | Cross-linked modified acrylic polymer |

| Appearance | Pale yellow powder |

| Applications | Water blocking agent for civil works and power cable |

Nippon Shokubai Business Fields

Careers

Contact

- TEL : +32 (0) 3 250 37 99

- E-mail : bd@nseurope.be