- HOME

- Investor Relations

- Overview

- Nippon Shokubai At a Glance

Key Points

Key Points

to Understand Nippon Shokubai

Learn about what Nippon Shokubai does, what makes us strong,

and how we create value for society — all explained in a simple and easy-to-understand way.

01

What's

Nippon Shokubai

all about?

Empowering Society and People with the Power of Chemistry

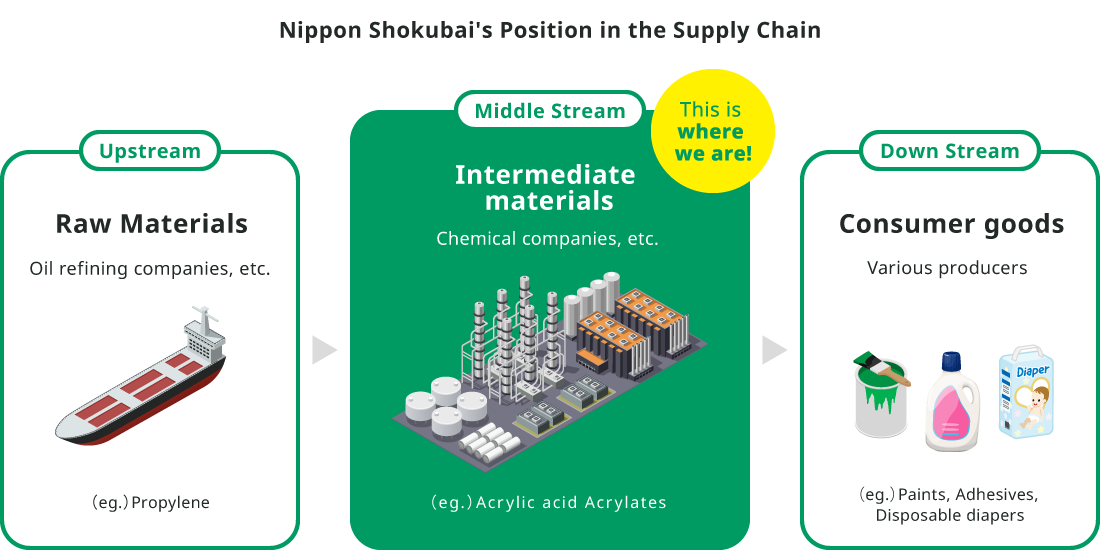

1. A Key Supplier of Intermediate Chemical Materials Supporting Various Industrial Applications

Nippon Shokubai is a chemical manufacturer that occupies a position in the middle of the chemical industry supply chain—between the upstream and downstream sectors. We purchase and process raw materials from upstream suppliers and deliver intermediate materials to downstream manufacturers that produce consumer goods.

Examples of consumer goods include paints, detergents, and disposable diapers.

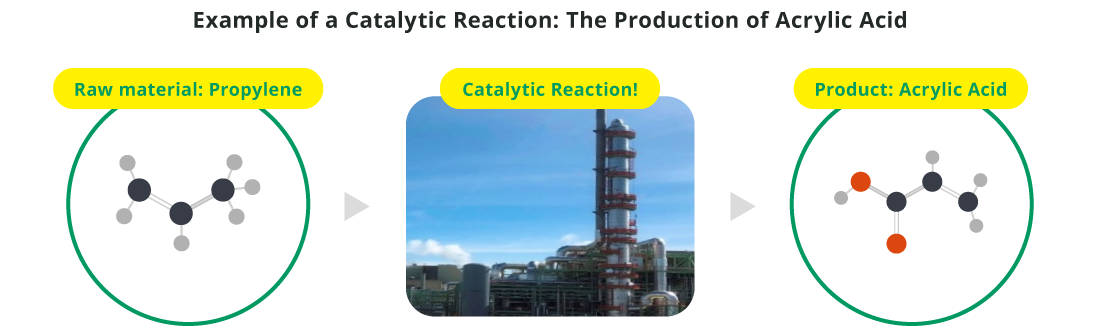

To give one example, we purchase a raw material called propylene from an upstream manufacturer and use a catalyst developed by our company to produce acrylic acid and aclyrates.

These products are then sold to manufacturers of paints, tapes, adhesives, and similar items.

2. Catalysts Enabling Low-Cost, Energy-Efficient Material Production

A catalyst is a substance that facilitates chemical reactions efficiently, at low cost and with minimal energy consumption.

The name "Nippon Shokubai" reflects our commitment to developing our own catalysts and using them to create a wide range of chemical products, driving our growth and innovation.

Acrylic acid is an essential material used in a wide range of products, including adhesives, paints, and coatings. It serves as a key raw material in the production of electronics, building materials, and everyday consumer goods.

In 1970, Nippon Shokubai became the first in the world to develop a new manufacturing process for acrylic acid that enabled large-scale, low-cost production.

3. Segments and Business Domains

Our company operates two core business segments: Materials and Solutions.

The Materials segment focuses on the global supply of high-quality materials through stable and large-scale production.

The Solutions segment leverages our long-standing R&D expertise to deliver unique, value-added functions that address our customers’ specific needs.

Each segment plays to its strengths, built over years of experience and innovation.

02

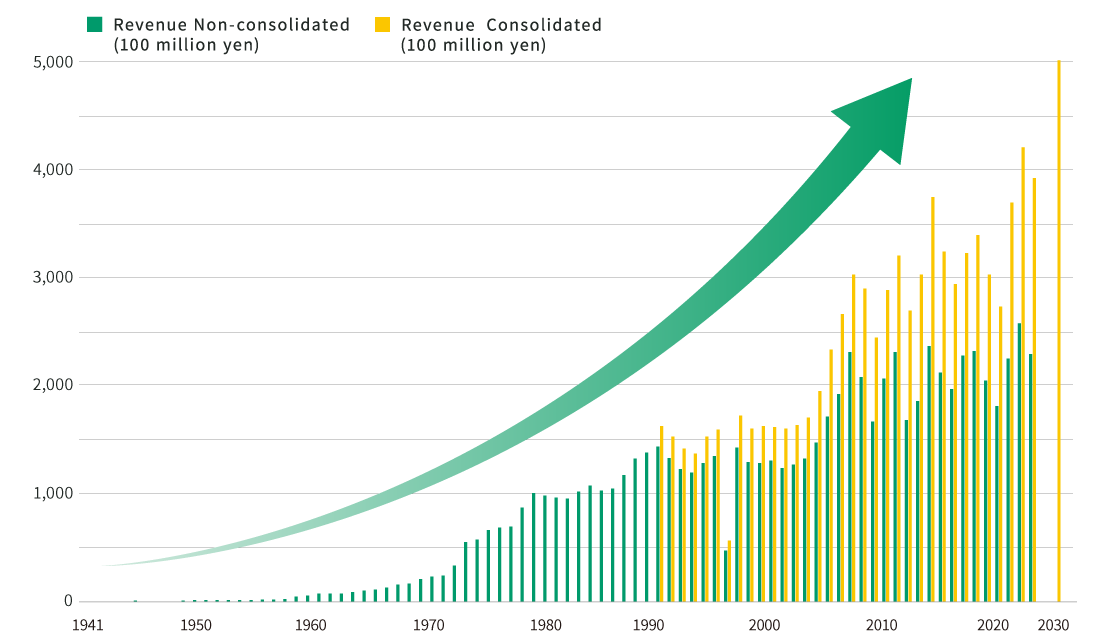

Nippon Shokubai’s Evolution and Expansion

Since our founding, we have continuously refined our unique research

and development capabilities and production technologies,

achieving numerous industry firsts in Japan and worldwide,

and driving our ongoing growth in the chemical industry.

03

What Makes Nippon Shokubai Strong

By leveraging our proprietary core technologies,

we seamlessly integrate research and development with production engineering,

continuously enhancing our competitiveness.

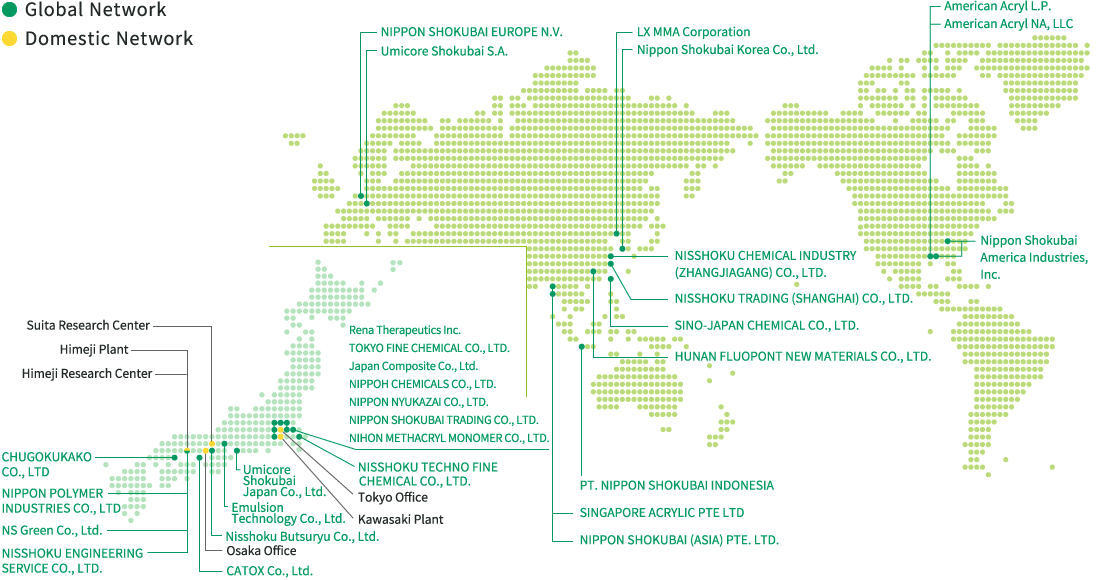

1. Established a global production and supply network

We leverage the expertise of our member companies across various fields—including chemical manufacturing, logistics, and trading—to generate strong group synergies.

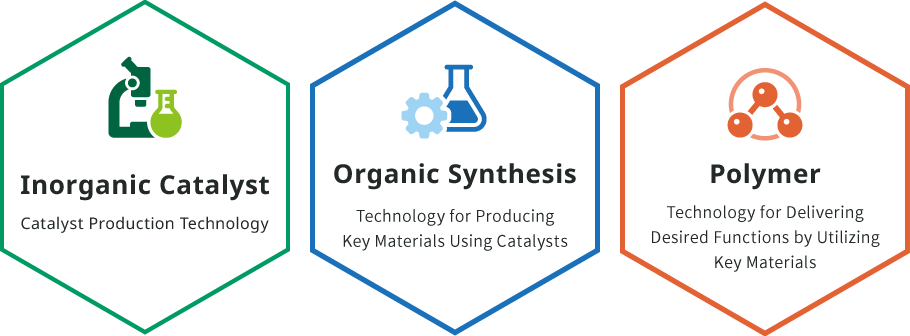

2. Three Core Technologies Driving the Creation of High-Value-Added Products

We leverage and advance our core technologies—inorganic catalysis, organic synthesis, and polymer - while actively developing and incorporating new innovations.

3. Approx. One-Fourth of the World's Disposable Diapers Use Products Made by Nippon Shokubai

POINT01

A global leading manufacturer of superabsorbent polymers

Disposable diapers have rapidly gained popularity thanks to superabsorbent polymers. These polymers exhibit excellent absorbency and water retention properties, capable of absorbing approximately 100 to 1,000 grams of water with just 1 gram of polymers.

Nippon Shokubai is a world-leading manufacturer of superabsorbent polymers, and according to our research, approximately one-fourth of all disposable diapers worldwide use our products.

POINT02

Leading the World with Superabsorbent Polymers

The market for superabsorbent polymers used in disposable diapers is expanding, with growing demand for baby diapers in emerging countries and adult incontinence products in developed nations. As a result, the market is growing at an annual rate of approximately 3%. This presents a significant business opportunity for Nippon Shokubai, which boasts one of the world's largest production capacities for superabsorbent polymers.

POINT03

Supporting Global Excellence: Our strength in Developing High-Quality Superabsorbent Polymers and Ensuring Reliable Supply

The reason Nippon Shokubai leads the world in superabsorbent polymers lies in its strong research and development capabilities, integrated production from raw materials, and a global manufacturing network. We design products tailored to customer needs, such as faster drying and higher absorbency, and utilize to shorten development cycles significantly.

With production sites in the U.S., Asia, and Europe, we ensure stable supply by manufacturing our products from acrylic acid in a fully integrated process. Furthermore, our acrylic acid production capacity ranks among the highest in the world, supported by an extensive global supply network.

POINT04

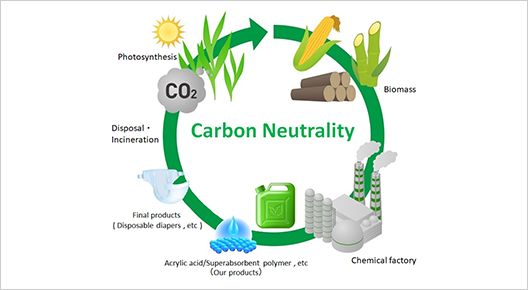

Superabsorbent polymer’s initiatives to realize Carbon Neutrality

Nippon Shokubai Group has established a four-region global supply system for ISCC PLUS-certified* superabsorbent polymer using biomass-derived raw materials allocated via the mass balance method.

We are also working on the scale-up of manufacturing processes and investigating market potentials aiming to start the commercial production of biomass-derived acrylic acid by 2030.

Furthermore, we are proceeding the development of new recycling technologies for superabsorbent polymer from used disposable diapers.

*ISCC PLUS Certification: It is a third-party certification program developed by International Sustainability and Carbon Certification (ISCC) System GmbH based in Germany to manage and guarantee sustainable raw materials and products such as biomass and recycled materials in the supply chain.

04

Nippon Shokubai

- It's Everywhere

We contribute to enhancing the quality and performance of products in your everyday life.

-

Bridge

AQUALOC™, a polymer for concrete admixtures, is used in the Akashi-Kaikyo Bridge and the Tokyo Bay Aqua-line, supporting Japan's infrastructure.

-

Pharmaceutical Products

Promoting GMP API contract manufacturing for Middle-molecular drugs:nucleic acids and peptides

-

Factories & Plants

Our Wastewater treatment catalyst are used in factories and plants.

-

Semiconductors

Silica particle, SEAHOSTAR™ are used as semiconductor materials.

-

Exterior wall paints

UWR™ Acrylic resin for paints is highly resistant to UV rays and water, which can cause deterioration, and has excellent weatherability.

-

Detergent for dishes & laundry

SOFTANOL™ is used in various detergent ingredients. In addition to its cleaning and penetrating power, it is also biodegradable.

-

Disposable diaper

AQUALIC™CA Superabsorbent polymer is used in disposable diapers, pet sheets, and refrigerant.

-

Cosmetics

Multifunctional polymers have moisturizing and antibacterial effects and are used as cosmetic ingredients.

-

PET bottle

Ethylene glycol is used as a raw material for plastic bottles and polyester fiber.

-

Ramen noodles (food additives)

Succinic acid is used as a food additive for flavor.

-

LCD display

ACRYVIEWA™, an acrylic resin for optical films, contributes to larger and thinner LCD displays in TVs, smartphones and tablets.

-

Electric vehicle

IONEL™, an electrolyte for lithium-ion batteries, contributes to longer battery life and shorter charging times.

05

Next

Growth Driver

Actively allocating resources to growth businesses that focus on strategic expansion in line with market growth.

-

Specialty Chemicals

We are globally expanding products that contribute to solving environmental and social challenges, such as water treatment agents that help prevent water pollution and CO2 absorbents expected to support carbon capture and storage.

-

Electronics

We aim to expand our market share in the advanced electronics areas with products such as resins for optical films used in large LCD displays and fine particles for next-generation displays and semiconductors.

-

Construction

In the construction chemicals market, which is expected to see global growth driven by population increase and urbanization, we are developing new products that contribute to reducing CO2 emissions and expanding our lineup of emulsions for civil engineering applications.

-

Energy (Batteries)

With the growing demand for lithium-ion batteries for electric vehicles (EVs), the demand for electrolytes—one of the key components of these batteries—is also expected to increase. In response, we are strengthening our production system in line with a local production for local consumption strategy.

-

Energy (Hydrogen)

Hydrogen and ammonia are gaining attention as next-generation energy sources that do not emit CO2. To help realize a decarbonized society, we are advancing technological development that contributes to building a hydrogen supply chain.

-

Health & Medical

By supplying active pharmaceutical ingredients (APIs) for medium-sized molecules, we support people's health and medical care, contributing to the future of society. Through increased production capacity, we are establishing a system capable of responding to large-scale international projects.