NEDO Selects Project for Developing Mass Production Technologies of Game-Changing Latent Heat Storage Microcapsules (h-MEPCM) -Joint Research by Nippon Shokubai, Hokkaido University, and Toyo Aluminium Speeds Up the Practical Implementation of Thermal Energy Storage Technology-

- Research and Development

NIPPON SHOKUBAI CO., LTD. (“Nippon Shokubai”) is proud to announce that its project, titled “Development of Mass Production Technology for Game-Changing Latent Heat Storage Microcapsules (MEPCM) and Their Molded Products,” has been selected for support under “Program to Develop and Promote the Commercialization of Energy Conservation Technologies to Realize a Decarbonized Society,” administered by Japan’s New Energy and Industrial Technology Development Organization (NEDO).

This project is a practical-phase technology development initiative based on the outcomes of the 2021 NEDO “New Energy and Environmental Technology Development Program.” Specifically, it builds upon the research and development of high-speed, high-density thermal energy storage technology using alloy-based latent heat storage microcapsules (h-MEPCM*1).

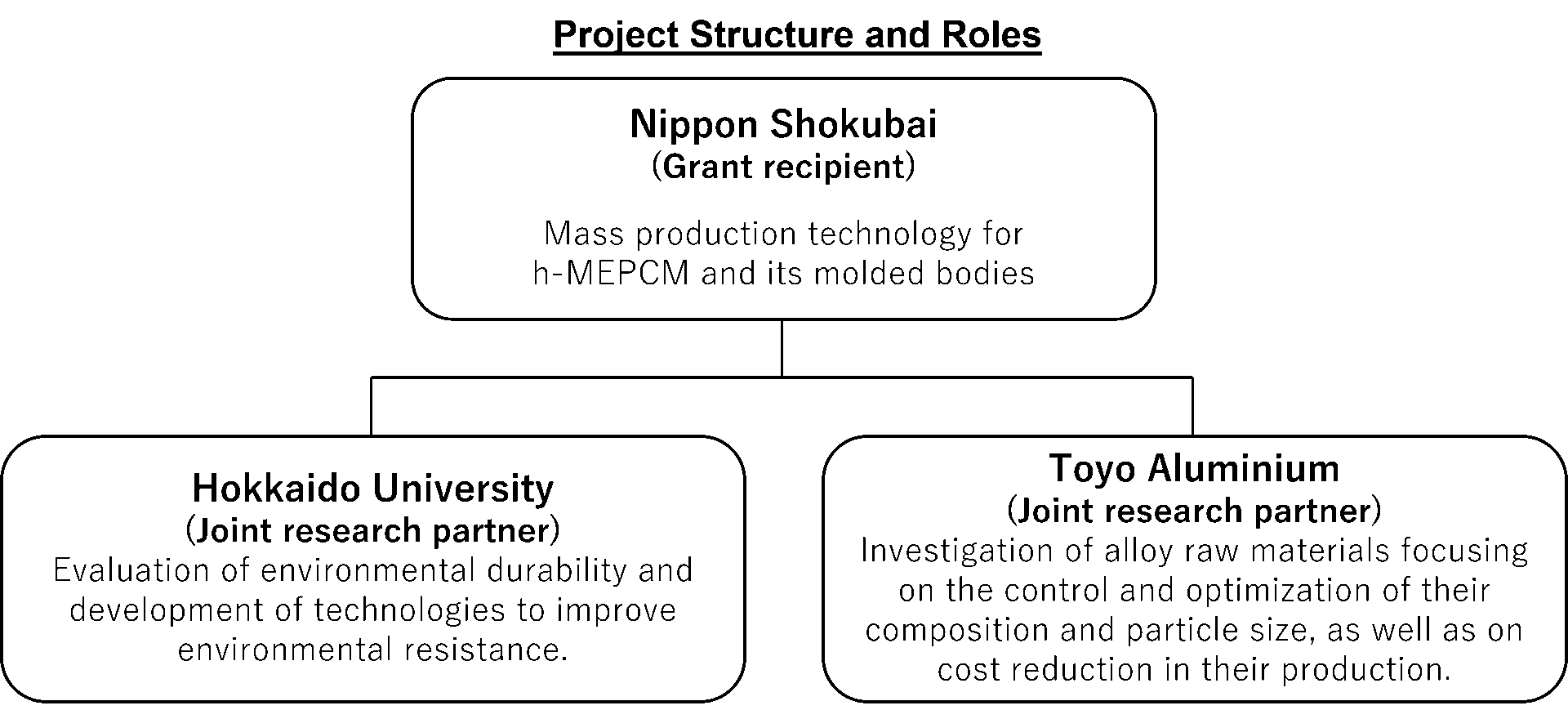

In this project, Nippon Shokubai has formed a joint research partnership with Professor Takahiro Nomura of the Center for Advanced Research of Energy & Materials, Graduate School/Faculty of Engineering, Hokkaido University (“Hokkaido University”), and Toyo Aluminium K.K. (“Toyo Aluminium”). Leveraging Toyo Aluminium’s expertise in alloy manufacturing, aluminum alloy produced at scale will be used as the raw material. The h-MEPCM powder developed by Hokkaido University will then be molded and mass-produced using Nippon Shokubai’s proprietary molding technology. The ultimate goal is to deliver application-specific molded products and make them widely accessible to society.

Social Background and Expectations for Thermal Energy Storage Technology

As part of global efforts to combat climate change, the adoption of renewable energy and the promotion of energy efficiency are gaining momentum. However, renewable energy sources such as solar and wind power are inherently weather-dependent, making it difficult to ensure a stable power supply. To overcome this issue, energy storage technologies have become essential.

While batteries are the most common method of energy storage, they face challenges in terms of cost and lifespan, which hinder widespread adoption. In contrast, thermal energy storage is gaining attention as a cost-effective alternative. Recently, technologies such as the “Carnot battery,” which converts electricity into heat for storage and then reconverts it into electricity when needed, have been actively developed for real-world implementation.

Thermal energy accounts for approximately 60% of energy consumption in Japan’s industrial sector and is used across a wide range of applications*2. However, the timing and location of heat generation often do not align with when and where it is actually needed, resulting in large amounts of surplus heat being wasted. By utilizing thermal energy storage technologies, this mismatch between supply and demand can be resolved, enabling the reuse of surplus heat and contributing significantly to energy savings.

Technical Advantages of h-MEPCM and Efforts toward Practical Application

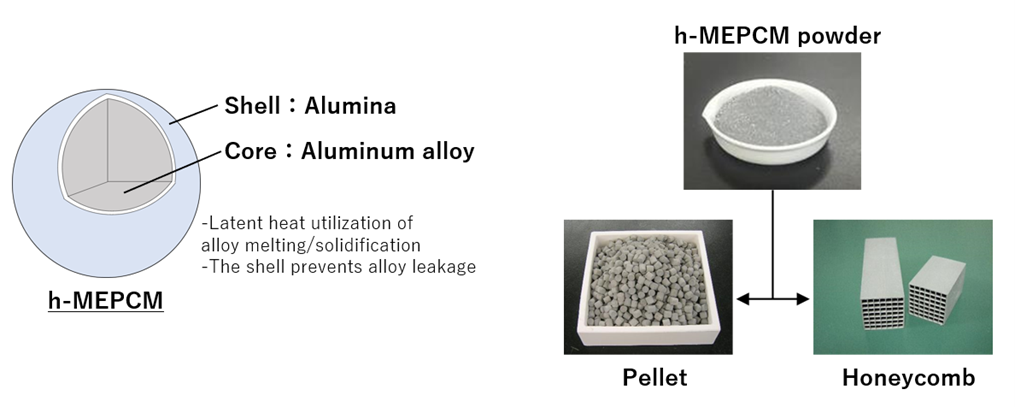

The h-MEPCM developed by Professor Nomura at Hokkaido University is composed of thermal storage particles about 30 microns in diameter, with a metal core that melts at approximately 600 ℃ encapsulated within alumina, which has a melting point above 2,000 ℃. The metal core absorbs a large amount of heat as latent heat during melting, enabling a higher thermal storage density than conventional sensible heat storage materials*3.

Conventional latent heat storage materials*4 have faced challenges such as handling difficulties due to the phase transition between liquid and solid states, and complex system design requirements caused by differences in thermal conductivity between phases. In contrast, h-MEPCM maintains a solid exterior thanks to its alumina shell, allowing it to be handled as easily as traditional solid storage materials like rocks or alumina balls, despite being a latent heat storage material. Also, it can be processed into molded bodies suitable for specific applications. Furthermore, the high thermal conductivity of the metal core enables efficient heat transfer to the outside, ensuring stable temperature control and high-output heat release.

Given these advantages, molded forms of h-MEPCM are expected to be applied across a wide range of fields, including high-temperature waste heat recovery, thermal management in industrial processes, and thermal energy storage for renewable energy systems. Specific applications include the reuse of electric arc furnace waste heat in the steel industry, energy-saving technologies such as regenerative burners*5 in high-temperature industrial furnaces, thermal-electric demand balancing in cogeneration*6 systems, heat storage for EV cabin heating, and the stable utilization of various renewable energy sources through integration with thermal storage technologies.

Through a tripartite collaboration that maximizes each partner’s strengths, this project aims to establish mass production technologies for molded thermal storage bodies optimized for real-world applications of h-MEPCM, while also reducing costs—thereby accelerating its commercial implementation.

*1: h-MEPCM: Microencapsulated phase change materials. The “h-” denotes Hokkaido University.

*2: “Study on Decarbonization in Thermal Processes of Industrial Sectors,” Energy and Resources from Japan Society of Energy and Resources, Vol. 44, No. 5, p.294, 2023

*3: Latent Heat Storage: A method of storing thermal energy by utilizing the heat absorbed or released when a material undergoes a phase change—such as from solid to liquid or vice versa.

*4: Sensible Heat Storage: A method of storing thermal energy by increasing the temperature of a material without changing its phase. The heat is stored as the material’s temperature rises and can be released as the temperature decreases.

*5: Regenerative Burner: A technology that recovers heat from the exhaust gases of high-temperature furnaces and stores it in a thermal storage medium. This stored heat is then used to preheat incoming combustion air, significantly improving energy efficiency. It is reported to achieve energy savings of over 30%.

*6: Cogeneration: A method of simultaneously producing electricity and heat from a single energy source. By incorporating thermal energy storage, cogeneration systems can bridge the gap between the timing of electricity and heat demand, enabling more efficient and flexible energy use.

Related releases

Contacts

NIPPON SHOKUBAI CO., LTD.

Corporate Communications Dept.

Contact us here

Hokkaido University

The Public Relations Division

kouhou@jimu.hokudai.ac.jp

Toyo Aluminium K.K.

Corporate Division General Affairs Unit Legal&Public Relation Teams

TEL 06-6271-3186 FAX 06-6245-4696