Nippon Shokubai Obtains ISCC PLUS for Bio-based Superabsorbent Polymers -To Contribute to the Reduction of the Environmental Impact of Disposable Diapers-

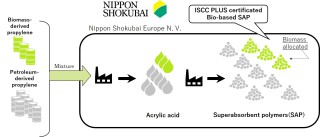

Nippon Shokubai has obtained biomass certification for superabsorbent polymers produced by its subsidiary Nippon Shokubai Europe N.V. (hereinafter “NSE”) from ISCC*1 (International Sustainability and Carbon Certification), with the aim of achieving carbon neutrality by 2050.

SAP, the key material for disposable diapers, is mainly made from acrylic acid produced from propylene. NSE produces both acrylic acid and SAP. NSE has recently obtained ISCC PLUS certification (mass balance method*2) from ISCC for the production of SAP utilizing acrylic acid produced from biomass-derived propylene. We will establish a system to supply bio-based SAP in response to customers’ requests. The quality of bio-based SAP is equivalent to that of conventional petroleum-derived products, and the use of bio-based SAP will contribute to the reduction of CO2 emissions throughout the product life cycle.

In addition to bio-based SAP, Nippon Shokubai is engaged in the research and development of sustainable SAP that contributes to the reduction of environmental impact, such as biodegradable SAP and recycled SAP, which is separated from used disposable diapers and restored to almost the same level of functionality as new ones. We will contribute to the realization of a sustainable society by promoting these research and development activities.

<Corporate outline of NSE>

Company name: NIPPON SHOKUBAI EUROPE N.V.

Established: February 1999

Location: Antwerp, Belgium (headquarters and plant)

Representative: Tomiyuki Sawada, President

Capital: 243 million EURO (100% owned by Nippon Shokubai)

Business: Production and sales of acrylic acid and SAP

Number of employees: 189 (as of September 30, 2020)

*1) ISCC(International Sustainability and Carbon Certification): ISCC is one of the world’s largest certification organizations, and is widely recognized in Europe and other parts of the world. It has a track record of more than 4,000 certifications in over 100 countries for sustainable raw materials, such as biomass and waste plastics, and recyclable products.

*2) mass balance method: When biomass-derived raw materials and petroleum-derived raw materials are mixed, the ratio of the biomass-derived raw materials used is assigned as the biomass ratio of the specific end product. For example, if 30% of the propylene used in the production of acrylic acid and SAP is bio-based propylene and the rest is petroleum-based propylene, the mass balance method can be applied to allocate 30% of the bio-based propylene to SAP. Therefore, biomass-derived and petroleum-derived raw materials can be manufactured up to completion of the final product without distinguishing between them, and the extent of the contribution to the reduction of CO2 emissions during the life cycle of the product can be shown.

[Files]

[Link]

https://www.shokubai.co.jp/en/company/aboutus.html#co02