Acrylic Rubber Microparticle-Dispersed Epoxy Resin : ACRYSET™ BP Epoxy Resin with Dispersed Acrylic Rubber Microparticles

- Main Applications

Adhesives, Sealing materials, Laminated plates, Composite materials, Paints, etc.

- Applications

- Functions

Basic Information

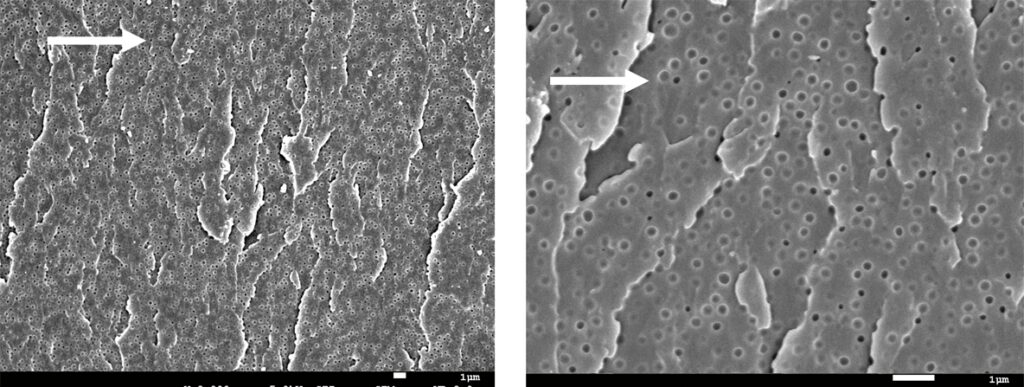

The ACRYSET™ BP series of products are epoxy resins with a sea-island structure before curing.

Nippon Shokubai’s proprietary acrylic rubber microparticles are evenly dispersed in bisphenol A epoxy resin and bisphenol F epoxy resin, which improves brittleness – the main defect of epoxy resin-cured products. It also eliminates variations in physical properties caused by curing conditions and reduced heat resistance, which are seen in the conventional technology of liquid rubber modified epoxy resin-cured products.

This means products cured using the ACRYSET™ BP series are highly resilient with little internal stress, and excellent adhesive force and crack resistance, making them suitable for use in various applications.

Features and Properties

- Toughness

- Heat-resistant (around 180-200℃)

- Significantly eases internal stress

- Strong adhesive force

- Excellent durability

- Excellent crack resistance

Uniform Dispersion of Acrylic Rubber in Epoxy Resin

Lineup

| Item Number | Base Epoxy Resin | Appearance | Viscosity (Pa·s, 25 ℃) | Epoxy Equivalent (g/eq.) | Acrylic Rubber Content (phr) |

|---|---|---|---|---|---|

| BPA328 | Bisphenol A Type | White, viscous liquid | 60 ±20 | 230 ±10 | 20 ±1 |

| BPF307 | Bisphenol F Type | White, viscous liquid | 13 ±5 | 210 ±10 | 20 ±1 |

Applications

For use with various epoxy resins that require heat resistance and toughness