Comprehensive Guide to Detergent Design Fundamentals and Applications

- Applications

- Functions

From household cleaners for clothes and tableware to industrial cleaners. Explains the basics of detergent design that can be used in a wide range of fields!

Basic Knowledge for Detergent Design

Detergents (cleaners) include household cleaners for laundry, kitchen, and home/furniture cleaners, commercial cleaners used in restaurants, and industrial cleaners used in specific environments such as factory lines and production facilities.

It is necessary to understand the scene of use, the material and surface condition of the targeted items, understand the nature of the soil (organic, inorganic, complex soils, etc.), organize the cleaning mechanism combining chemical and physical actions, and design in accordance with the environment, safety, and operating conditions.

Types and Roles of Ingredients in Detergents

① Surfactants

Surfactants play a major role in removing soil and are often used as the main component of detergents. Appropriate types and combinations of surfactants are selected from anionic, cationic, nonionic, and amphoteric surfactants, taking into consideration the type of soil, the substrate, foam control, stability, operating conditions, safety, and environment.

SOFTANOL™ (secondary alcohol ethoxylate), a nonionic surfactant, is used in a wide range of applications, from household cleaners to industrial cleaners, with a lineup that includes low-foaming numbers.

② Detergent Builders

Detergent builder, an essential additive for detergents, is a general term for components that assist the effect of surfactants to improve cleaning performance and product stability. In addition to the design of surfactants, which are the main components, the selection of detergent builder is also a key to detergent design.

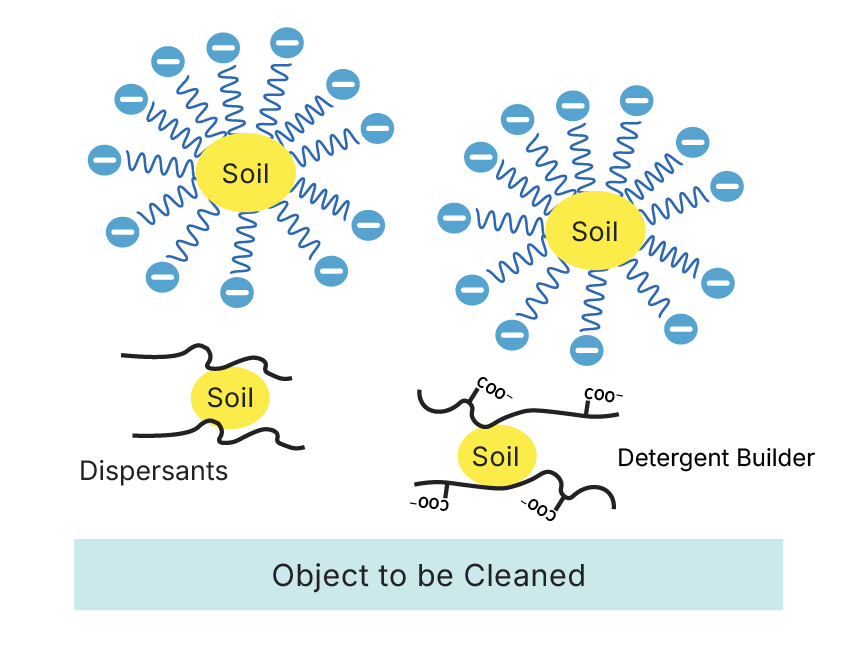

Dispersant

- Disperses soil and particles evenly in water to prevent redeposition.

- In the case of cleaning agents for clothes, prevents graying of clothes.

- Removes and stabilizes inorganic particles (Scale, rust powder, abrasive, etc.).

- Prevents scales from depositing such as calcium carbonate in alkaline cleaning.

Alkaline Agent

- Increases the pH of the cleaning agent and efficiently decomposes dirt.

- Neutralizes and removes acidic soil and scale.

- Dissolves and removes metal oxides and light corrosion products adhering to metal surfaces, such as aluminum, leaving the surface clean.

- By incorporating ethanolamine, the cleaning solution becomes alkaline which promotes the decomposition of oily soils and the saponification.

Chelating Agent

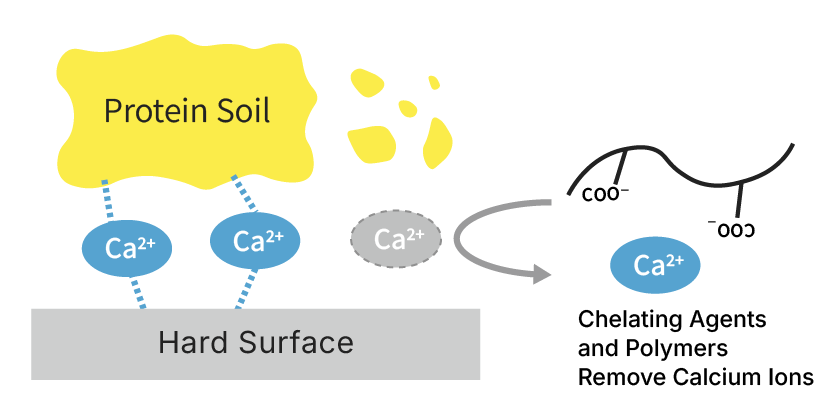

- Captures metal ions such as calcium, magnesium, and iron present in water or complexed soil, preventing them from interacting with surfactants leading to inhibit the cleaning performance.

- Among chelating agents, there are polymer-type chelating agents, and some grades can be formulated with sodium hypochlorite.

- Effective for removing soils where metals (e.g. calcium) act as binders, including protein and fatty acid metal salts (soap scum).

| SOFTANOL™ | AQUALIC™ KL-001 | AQUALIC™ FN-001 | AQUALIC™ L | Polyethyleneimine Ethoxylate (PN-100) | Biodegradable Chelating Agent HIDS™ | |

|---|---|---|---|---|---|---|

| Dispersibility | 〇 | 〇 | 〇 | 〇 | 〇 | |

| Chelating Ability | 〇 | 〇 | 〇 | |||

| Compatibility for Liquid Detergents * | 〇 | 〇 | 〇 | 〇 | ||

| Anionic Surfactant Boost | 〇 |

*Demonstrates high formulation stability across a wide range of compositions without causing separation or cloudiness.

Please use the form to inquire about our detergents or detergent builders.

③ Other Additives

In addition to surfactants and cleaning aids (builders), there are other components (other additives) that play an important role in detergent design. This section describes commonly used additives.

Stabilizers

- Stabilizers include discoloration inhibitors (antioxidants), preservatives, compatibilizers, and solubilizers, and are selected according to the intended purpose and characteristics of the detergent.

- Compatibilizers improve the compatibility of different components in the detergent (e.g. oily and aqueous components), preventing separation and maintaining product stability.

- Solubilizers disperse components that are difficult to dissolve in water (Flavors, oils, etc.) and dissolve them evenly in the aqueous solution.

pH Adjusters

- Maintains the pH of the detergent within an appropriate range to optimize the cleaning effect and prevent damage to the cleaning target.

- Depending on the application of the detergent, it can be adjusted in a wide range from acidic to alkaline.

Thickeners

- Adjust the viscosity of detergents and improve their usability.

- By controlling the viscosity of liquid laundry detergent, prevent run-off and enhance contact with soils for improved cleaning performance. They also improve product stability and keep the ingredients evenly dispersed.

- Polyacrylic acid and sodium polyacrylate are used as water-soluble thickeners.

Enzymes

- Make stains easier to remove by breaking down specific stains.

Mechanism of Soil Removal with Detergents

Types of soils include oily soils such as sebum and various oils, as well as water-soluble soils such as food stains, salt, sugar, and perspiration. Since many soils are mixtures of both oily and water-soluble components, cleaning must be tailored to the specific soil characteristics. The following describes the mechanisms of soil removal.

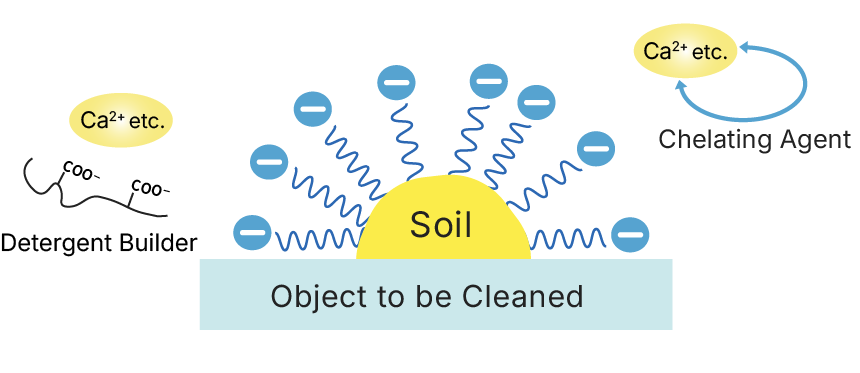

In cleaning formulations, the hydrophobic moiety of the surfactant adheres to soils present on the substrate. Surfactant deactivation caused by hardness ions, such as calcium or magnesium, can be prevented by adding chelating agents or builders to the cleaning agent.

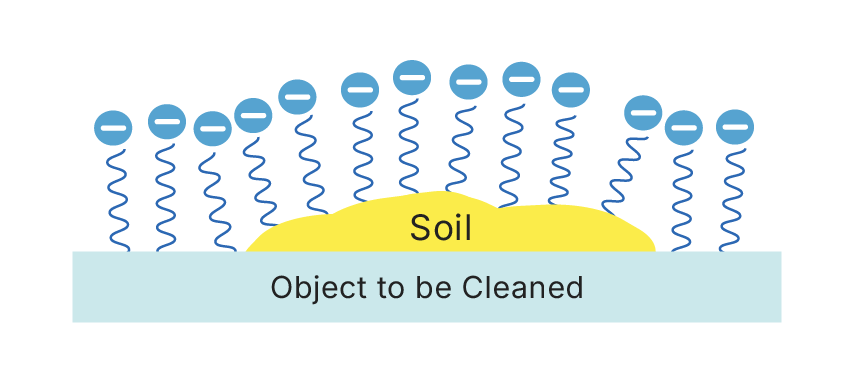

Adequate surfactant concentration allows its hydrophobic moieties to encapsulate both the substrate and the soil.

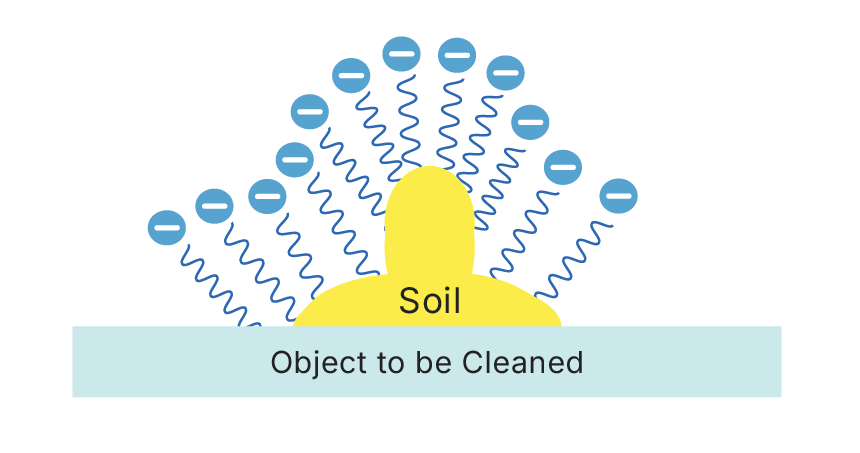

In water, the dirt is surrounded by the surfactant and removed from the object to be cleaned. The hydrophilic group (-) mixes with water and works as an emulsifier.

Soil is dispersed in water and finely distributed during cleaning. Builders (e.g., sodium polyacrylate) help prevent soils from redepositing onto substrates.

Key Points of Cleaning Agent Design Learned from Case Studies

①Example of Concentrated Detergent

Cleaning aids needed for the new eco-friendly cleaning agent

【Keywords】 boosting effect by coexisting with anionic surfactants

② Example of Dishwasher Application

Polymer enhances cleaning performance

【Keywords】 high compatibility with surfactants, anti-scaling ability, anti-re-soiling properties

Switch to more environmentally friendly ingredients

【Keywords】 EDTA substitute, not subject to the PRTR system, polymer-type chelating agent

③ Example of Machine Parts Cleaning Application

Balance cleaning and environmental load

【Keywords】 nonionic surfactant, low foaming, ability to clean metal oil stains