In development Highly Compatible Multifunctional Polymer (AQUALIC™ KL-001) Special polymer

- Main Applications

Various industrial detergents, detergents for household, dispersants and solubilizers

- Applications

- Functions

Basic Information

In addition to the polymer dispersion function, AQUALIC™ KL-001 has the functions of a dispersant and a solubilizer due to its high compatibility with surfactants. It can supplement the functions of other raw materials such as solubilizers and dispersants.

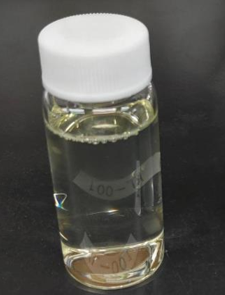

| Appearance | light brown transparent liquid |

|---|---|

| Solid fraction | 65% (aqueous solution) |

| Viscosity (25℃) | ≦ 1,000 mPa・ s |

| pH (25℃) | 2.5 ~ 3.5 |

| Density (25℃) | 1.14 g/ml |

Product Details

- Highly compatible with surfactants

- Ability to prevent scale

- Ability to prevent re-contamination

| Performance | Chelating agent | Conventional polymer (sodium polyacrylate) | KL-001 |

|---|---|---|---|

| Compatibility with surfactants | Poor | Poor | Excellent |

| Scale inhabitation ability | Fair | Good | Good |

| Ability to prevent redeposition | Poor | Good | Good |

Features and Properties

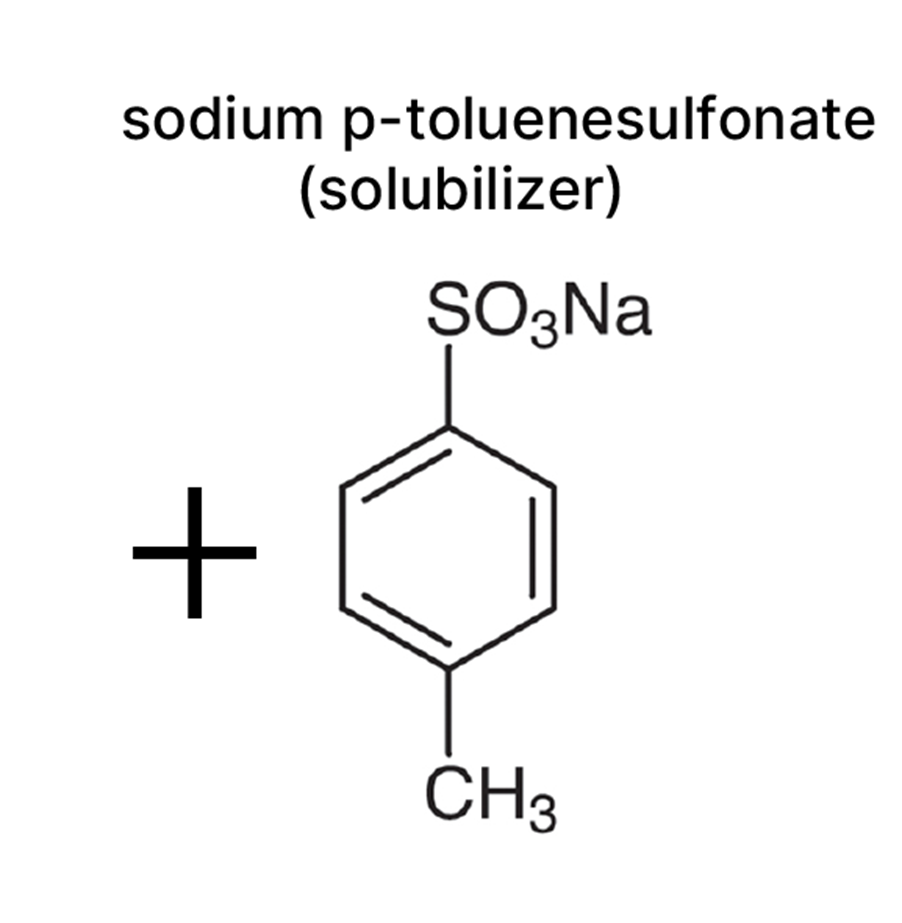

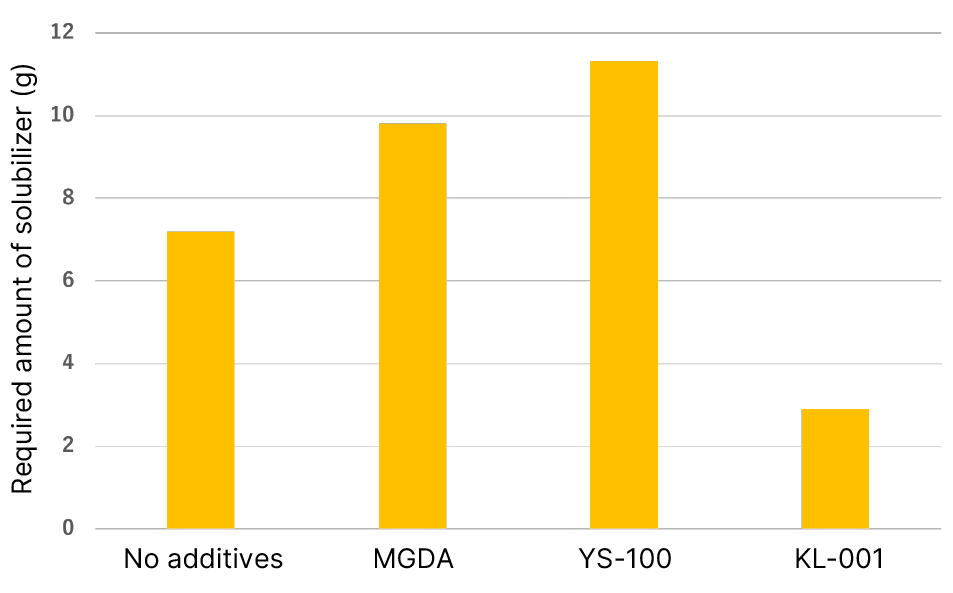

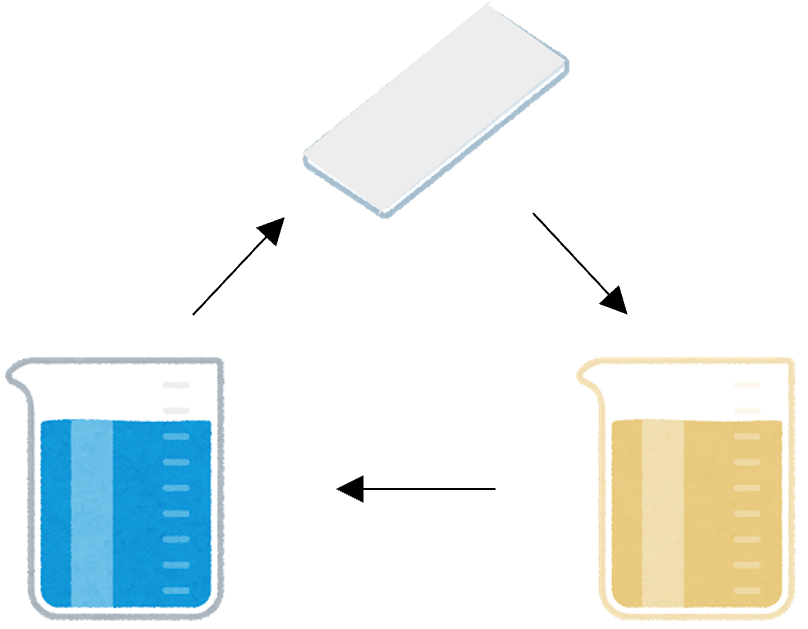

■ Solubility with low-foaming nonionic surfactants

| Detergent composition | g |

|---|---|

| Nonionic surfactant (PEG/PPG-12/35 copolymer) | 1 |

| additive | 10 |

| NaOH | 5 |

| Water | 84 |

Prepare the detergent composition, adjust the temperature to 40℃, and add the solubilizing agent until the liquid becomes clear.

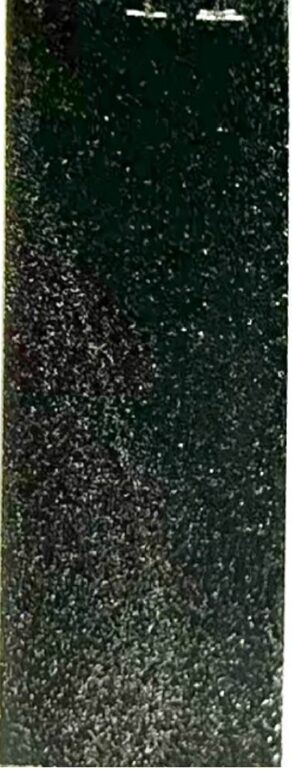

■ Scale inhabitation performance

Dilute the detergent at the specified magnification and insert the test piece.

After standing at the specified temperature for the specified time, visually observe the appearance of the test piece.

(Evaluation conditions are as follows)

| Detergent composition (wt%) | ① | ② | ③ | ④ | ⑤ | ⑥ |

|---|---|---|---|---|---|---|

| NaOH/Na2CO3=1/1 | 0 | 10 | 10 | 10 | 10 | 10 |

| MGDA・3Na | 0 | 0 | 10 | 7 | 5 | 0 |

| KL-001 | 0 | 0 | 0 | 3 | 5 | 10 |

| Appearance of SUS specimen |  |  |  |  |  |  |

(Evaluation conditions) Detergent concentration: 0.1% / Dilution water hardness: 300 mgCaCO3 / L / Standing temperature: 60℃ / Standing time: 24h / Test specimen: SUS304

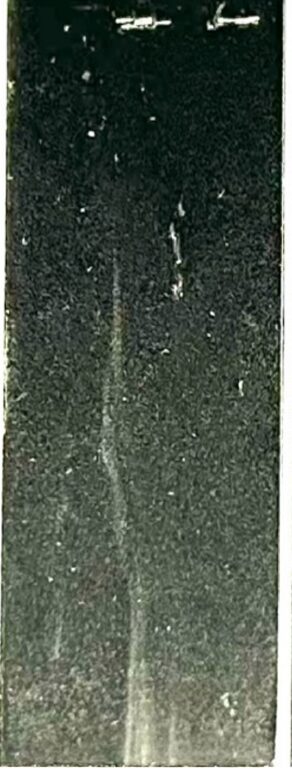

■ Ability to prevent redeposition of protein dirt

Mix the dirt and detergent and heat at a specified temperature for a specified time.

The process of soaking in the mixture for a specified time, soaking in rinsed water, and drying is performed three times.

Color is indicated with amide black and the absorbance is determined.

| Detergent composition (wt%) | ① | ② | ③ | ④ |

|---|---|---|---|---|

| NaOH/Na2CO3=1/1 | 0 | 10 | 10 | 10 |

| sodium p-toluenesulfonate | 0 | 0 | 10 | 0 |

| KL-001 | 0 | 0 | 0 | 10 |

| Appearance of glass specimen |  |  |  |  |

| Amide black content (ppm) | 2.44 | 1.27 | 1.51 | 0.59 |

(Evaluation conditions) Detergent concentration: 0.1% / Stain: 1% whole egg (oiled egg) / Heating temperature: 60℃/Heating time: 30min / Test specimen: Glass plate / Soaking time: 20sec (contaminated liquid), 5sec (rinsed water) / Water used: Tap water.

Examples of Applications

■ Example of liquid detergent formulation

| Detergent composition (wt%) | ① | ② |

|---|---|---|

| NaOH | 5 | 5 |

| SOFTANOL™ 70※1 | 1 | 1 |

| MGDA (40%) | 20 | 10 |

| KL-001 | 0 | 10 |

| Water | 74 | 74 |

| 40℃ Appearance |  |  |

※1 Cloud point of SOFTANOL™ 70: 33℃.