Waste Gas Treatment Catalysts Waste Gas Treatment Catalysts

- Applications

- Functions

Basic Information

Nippon Shokubai has been producing waste gas treatment catalysts (complete oxidation catalysts of VOC, malodorous substances, etc.) based on the catalyst technology we have accumulated since our establishment, and under strict quality control. These catalysts deliver stable performance over extended periods.

Nippon Shokubai’s waste gas treatment catalysts use noble metals such as platinum (Pt) and palladium (Pd) as the main components, which gives them an excellent purifying effect even in the low temperature range.

The table below shows some examples of our waste gas treatment catalysts. We propose the optimal catalyst based on the components of the waste gas.

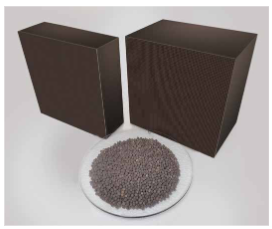

Waste Gas Treatment Catalysts: Types and Properties

| Shape | Series | Size | Features |

|---|---|---|---|

| Honeycomb | CH-700 Series | 150 mm × 150 mm × 50 mm (L) | For standard use |

| CH-800 Series | Heat-resistant | ||

| Spherical | C-700 Series | ø3 – 5 mm | For standard use |

| C-800 Series | Heat-resistant | ||

| C-900 Series | Pretreatment |

Features and Properties

- Excellent performance across a wide temperature range—from low to high temperatures.

- High deodorizing efficiency using noble metals such as platinum and palladium.

- Lineup includes catalysts with excellent heat and poison resistance ; heat-resistant types proven for long-term use at 700℃.

- Honeycomb structure combines low pressure drop with stable performance.

- Able to propose the optimal catalyst based on the components of the waste gas.

- Enables lower-temperature treatment than direct combustion, reducing energy costs and CO₂ emissions through reaction heat utilization.

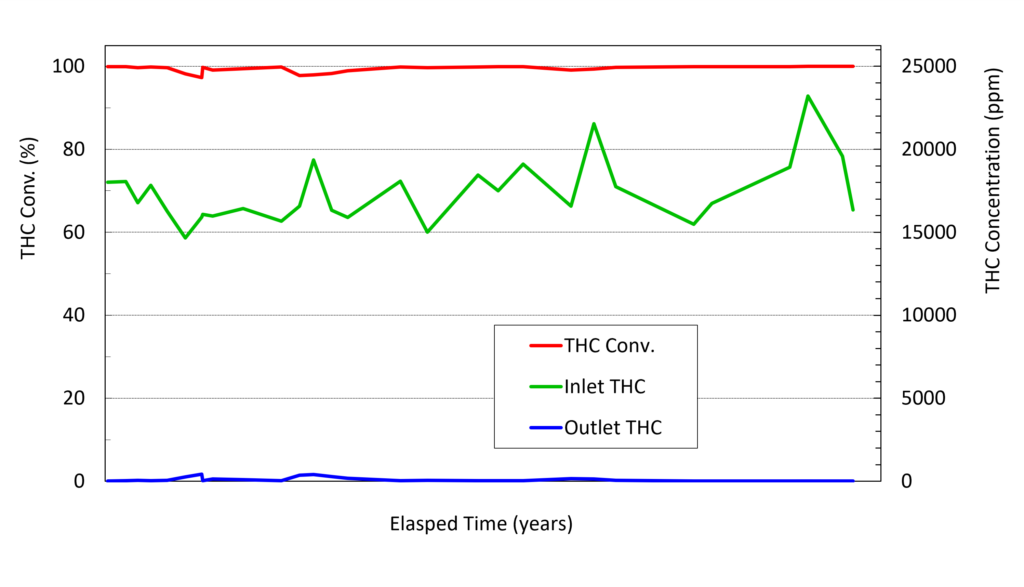

Heat-Resistant CH-800 Series

The CH-800 Series has an excellent heat resistance above 700℃.

Temp. : ≧700℃

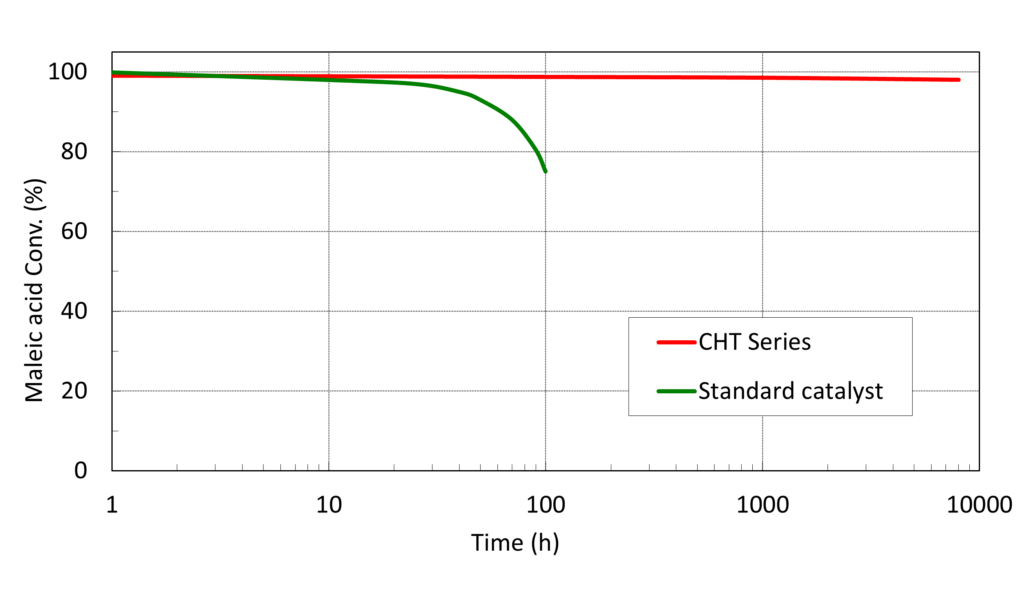

Sulfur-Resistant CHT Series

The CHT Series is resistant to catalytic poisoning by sulfur compounds.

Temp. : 300℃

Applications