Nippon Shokubai Announces Joint Development of a New Process for Biomass Utilization with Kobe University

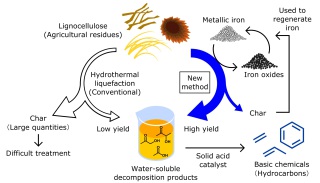

NIPPON SHOKUBAI CO., LTD. [Headquarters: Osaka, Japan; President: Yujiro Goto], hereinafter “Nippon Shokubai”, has jointly developed a new process for biomass(*1) utilization with the endowed chair “Sustainable Chemistry” [Specially Appointed Professor: Dr. Yuichi Kita] at the Graduate School of Engineering, Kobe University, hereinafter “Kobe University.” This process is a highly efficient method for decomposing lignocellulose(*2) into a group of water-soluble compounds that consist mainly of 2-6 carbon atoms. It is carried out in hot water at 250-300 °C in the presence of metallic iron. Unlike the conventional methods, this method reduces useless consumption of biomass resources and enables an efficient utilization of the whole biomass. Furthermore, by using a solid acid catalyst such as ZSM-5, the obtained water-soluble compounds can be converted to olefinic hydrocarbons, such as ethylene, propylene, and butylene, or aromatic hydrocarbons, such as benzene, toluene, and xylene (Fig. 1). These hydrocarbons are considered as promising basic raw materials for various green chemicals(*3). For example, if propylene produced from biomass could be supplied to an existing acrylic acid plant, we could produce green acrylic acid, which in turn can be used to produce environmentally-friendly super absorbent polymers (the raw materials for many products, such as disposable diapers).

Nippon Shokubai is continuing to challenge this new technology for a better future. Our future plans include promoting research and development of this new utilization process as well as the manufacturing of various green chemicals using the produced water-soluble compounds. This process is expected to help in establishing sustainable chemical industries, because it converts renewable carbon resources such as biomass into raw materials for chemicals instead of relying on fossil resources.

Summary of the Developed Process

Recently, interest in utilizing biomass as raw materials for fuels and chemicals has been growing due to concerns about depletion of fossil resources and greenhouse gas emissions. Hydrothermal decomposition (hydrothermal liquefaction) is one of the known technologies for biomass utilization. In this method, biomass is thermally decomposed in high-temperature water to obtain water-soluble and oil-soluble decomposition products. However, this conventional method (in the absence of metallic iron) has a low yield of the water-soluble and oil-soluble decomposition products (around 15 wt% each). Moreover, additional de-oxidation processes are necessary, because the oxygen content in the decomposition products is high. In addition, the large quantities of char produced (around 40 wt%) require treatment, which is considered one of the biggest challenges facing this process.

On the other hand, metallic iron, which coexists and reacts in the new process, results in high yield of water-soluble decomposition products of about 60 wt%. In addition, the process reduces the oxygen content in the water-soluble decomposition products by about two out of ten compared to that in the raw material. Furthermore, a higher degree of deoxygenation and hydrogenation is obtained. Moreover, decomposition, deoxygenation, and hydrogenation can be further promoted by adding a metal that has a hydrogenation capability, such as copper or palladium, resulting in a higher degree for the water-soluble decomposition products. Additionally, the whole biomass could be efficiently utilized, because char, which is a by-product of the process and represented a major problem in the conventional method, can be used as a reducing agent for regenerating metallic iron.

Some of the above results have been published in the scientific journal, ACS Sustainable Chemistry & Engineering (DOI: 10.1021 / acssuschemeng.7b00381), and presented at the 253rd American Chemical Society National Meeting & Exposition (April 2-6, 2017, San Francisco, USA).

About the Collaborative Research

The endowed chair “Sustainable Chemistry” at Kobe University [Specially Appointed Professor: Dr. Yuichi Kita] was established in July 2012 to develop new industries using sustainable chemistry. Nippon Shokubai started a collaborative research with the endowed chair at Kobe University in October of the same year and has been supporting research projects with an immediate impact on the industry, such as replacing raw chemical materials manufactured from fossil resources by ones derived from renewable resources.

【Glossary】

*1 Biomass

A concept representing the quantity (mass) of biological resources (bio). It is defined as “renewable organic resources, derived from biological origins.” When “Biomass” is exposed to combustion, decay, fermentation, or a similar process, it generates carbon dioxide, However, carbon dioxide is again absorbed and converted to biomass via photosynthesis, which closes the carbon cycle in the atmosphere, i.e., biomass exhibits “carbon neutral” characteristics.

*2 Lignocellulose

A type of biomass whose structure contains strongly bonded cellulose, hemicellulose, and lignin. It is found in wood and agricultural residues, and it is the most abundant type of biomass on earth. Cellulose and hemicellulose are polysaccharides, which can be decomposed into monosaccharides by hydrolysis. Lignin is a complex class of sterically polymerized polyphenol molecules.

*3 Green chemicals

Green chemicals are chemical products derived from biomass resources (explained here).

ABOUT NIPPON SHOKUBAI: Since 1941, Nippon Shokubai has grown up its business with unique catalyst technology. Nippon Shokubai has supplied, for example, Ethylene oxide, Acrylic acid, automobile catalyst, process catalyst and so on. Among all, our global market share of superabsorbent polymer comes up to No.1, now. Nippon Shokubai is a global chemical company with its corporate mission as “Providing affluence and comfort to people and society, with our unique technology”.

【Contacts】 Investor & Public Relations Dept.,

NIPPON SHOKUBAI CO., LTD.

E-mail: shokubai@n.shokubai.co.jp

https://www.shokubai.co.jp/en/

Fig. 1.Schematic diagram of the new utilization process for biomass compared to the conventional process

Fig. 1.Schematic diagram of the new utilization process for biomass compared to the conventional process