Introducing the solution for the production plan optimization with AI (Algorithm)

- Management and Business

NIPPON SHOKUBAI CO., LTD. (Headquarters: Osaka, Japan, President: Kazuhiro Noda, hereinafter “Nippon Shokubai”) announces that in collaboration with ALGO ARTIS CORPORATION (hereinafter “ALGO ARTIS”) it has developed an optimization solution for the production planning of superabsorbent polymers (SAP) with an Algorithm (AI) and has started its official operation.

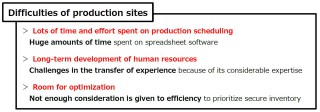

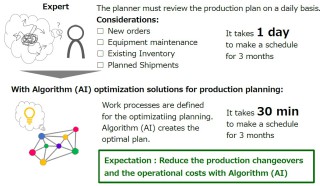

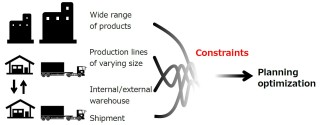

Nippon Shokubai’s technology used to produce SAP and acrylic acid, which is the primary raw material of SAP, is amongst the highest capacity in the world. SAP is a polymer which has high water absorption and retention. 1g of SAP absorbs 100-1000g of water. SAP is used for various purposes such as disposable diapers. Nippon Shokubai executes a lot of product changeovers and produces various types of SAP which have different production conditions in order to meet the desired needs, including a wide variety of absorption properties corresponding to those purposes. There were difficulties, such as a huge amount of labor spent for planning, because SAP production involved many product changeovers to meet all the complicated constraints. There was also a limit to the amount of information a human could consider. Furthermore, there were challenges such as the development of human resources with abundant knowledge and experience.

Nippon Shokubai has developed the long-term vision “TechnoAmenity for the future” in April 2021 and listed the construction of the more effective production system, utilizing DX (Digital Transformation), as one of the strategies. Nippon Shokubai has made the concept of optimizing production planning with Algorithm (AI) and advanced development together with ALGO ARTIS. We have succeeded in building Algorithm (AI) including the know-how Nippon Shokubai had accumulated. After completing all the validations and modifications, the Algorithm (AI) optimization solution for production planning will kick into gear in October 2022 in Himeji plant. This solution makes it possible to create production plans which are more effective, stable and long-term, in a much shorter time than before. Moreover, it contributes to a more sustainable supply of SAP, energy savings and reduced CO2 emissions.

In addition to the enhancement of SAP competitiveness through the reduction of field operation, energy loss and production loss, which is achieved by selecting the optimal production line and reducing product changeovers, Nippon Shokubai will promote transformations with DX, such as applying the Algorithm (AI) optimization solutions for production planning to other products.

About NIPPON SHOKUBAI: Since 1941, Nippon Shokubai has grown up its business with unique catalyst technology. Nippon Shokubai has supplied, for example, ethylene oxide, acrylic acid, automobile catalysts, process catalysts and so on. Among all, our global market share of superabsorbent polymers is the largest in the world now (according to Nippon Shokubai research). Nippon Shokubai is a global chemical company operating under its corporate mission “TechnoAmenity – Providing prosperity and comfort to people and society, with our unique technology.”

https://www.shokubai.co.jp/en/

【Contacts】

Corporate Communications Dept.,

NIPPON SHOKUBAI CO., LTD.

TEL: +81-3-3506-7605 E-mail: shokubai@shokubai.co.jp

[Files]