Development of novel marine biodegradable plastics in the NEDO’s project -Marine biodegradable materials with high gas barrier properties for packaging and agricultural applications-

- Sustainability

- Research and Development

NIPPON SHOKUBAICO., LTD. (Headquarters: Osaka, Japan, President: Kazuhiro Noda, hereinafter “Nippon Shokubai”) and Bioplastic Research Team, RIKEN, Center for Sustainable Resource Science (Team Leader Hideki Abe, Senior Scientist Yasumasa Takenaka, hereinafter “RIKEN”) successfully developed novel marine biodegradable plastics in the “Technology Development Project for Social Implementation of Marine Biodegradable Plastics”*1 commissioned by NEDO (New Energy and Industrial Technology Development Organization), in which they have participated since 2021.

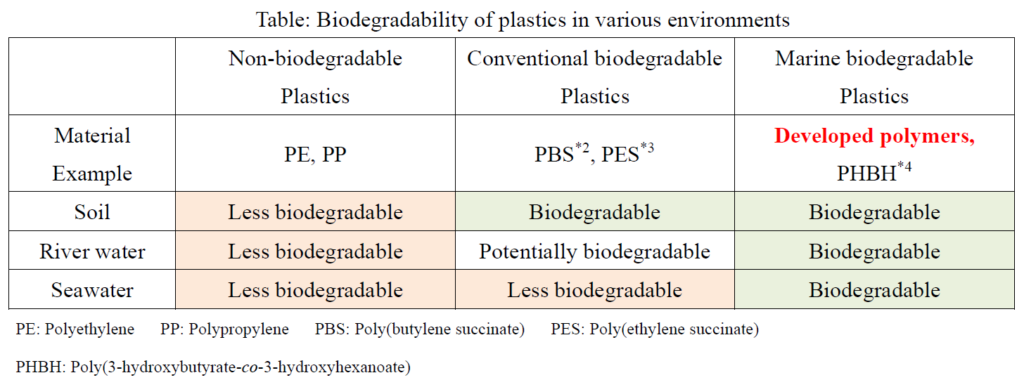

Plastics are widely used as convenient materials in our lives because of their light-weight, durability, and good workability. However, their high chemical stability precludes degradation in the natural environment. Therefore, plastics entering the oceans are causing increasingly serious marine pollution. Currently, biodegradable plastics are not extensively utilized and formulated to degrade in soil or compost on land, with very few designed to biodegrade in the oceans. In the project, we are conducting cutting-edge research and development ahead of the world with the aim of contributing to reduction of marine plastic waste in the future by implementing marine biodegradable plastics.

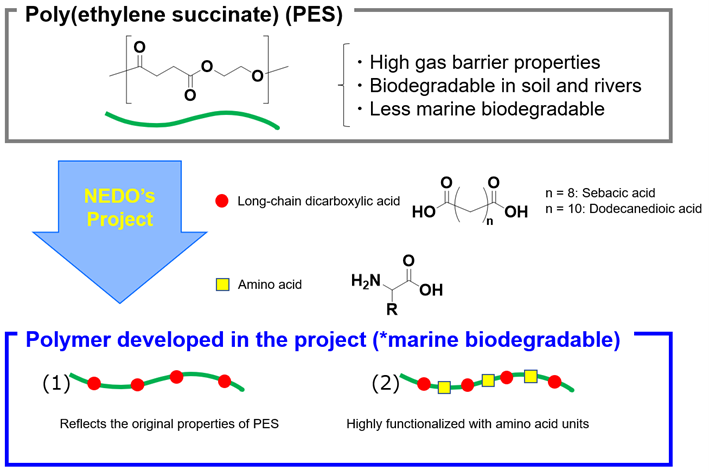

Nippon Shokubai and RIKEN have collaborated to design and develop marine biodegradable plastics, with efforts focused on polyethylene succinate (PES) as the basic structure. PES has high gas barrier properties and biodegradability in soil and rivers. Nippon Shokubai has PES-manufacturing experience, such as pilot production, but the problem was that PES is difficult to biodegrade in the oceans. Therefore, Nippon Shokubai has partnered with RIKEN, leveraging RIKEN’s expertise in marine biodegradable plastics, to create marine biodegradable plastics with the similar properties as PES.

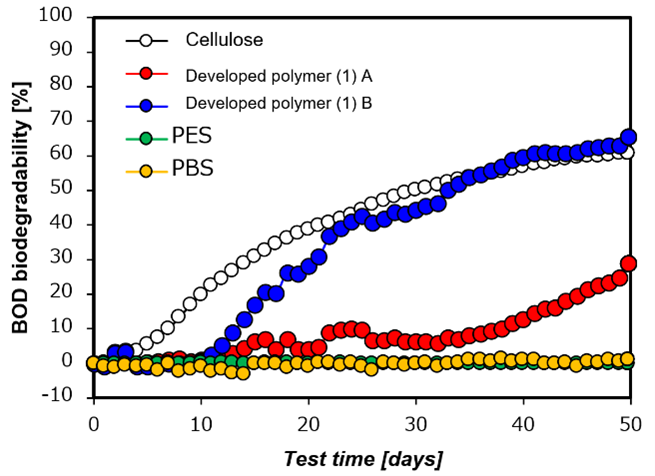

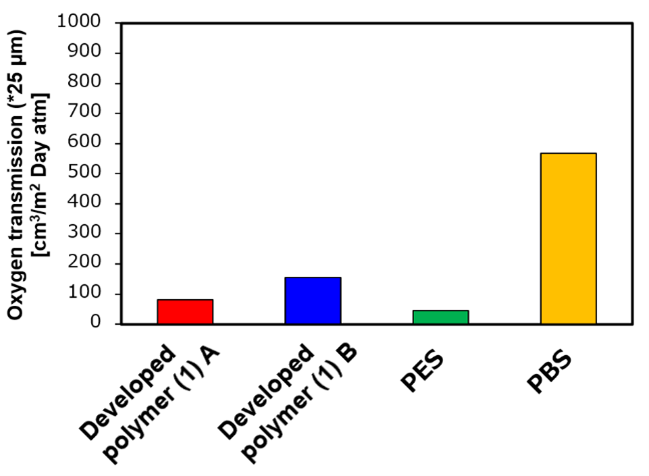

Nippon Shokubai and RIKEN found that polymers containing long-chain dicarboxylic acid*5 units into the PES backbone have biodegradability in seawater similarly to cellulose, which is known for its easy biodegradability in the oceans. Novel marine biodegradable plastics made from the polymers exhibit the advantageous properties of PES such as high gas barrier properties. Furthermore, they have diverse mechanical properties based on the specific units introduced into the polymer structure. These properties enable various applications, including packaging, agricultural, and civil engineering and construction materials. Now, scale-up studies are going on to establish a mass production process with the aim of accelerating commercialization.

The project also involves developing a novel marine biodegradable ester-amide polymer by introducing natural amino acid units into a PES-based polymer structure. These polymers should provide marine biodegradable plastics with exceptional functionality.

Some details of the novel marine biodegradable plastics has been published in Polymer Journal (Springer Nature), DOI:10.1038/s41428-023-00871-9.

*1 Project name: Technology Development Project for Social Implementation of Marine Biodegradable Plastics/ Development of New Technology and Material for Marine Biodegradable Plastics/ Development of novel marine biodegradable poly(ester-amide) resins

Project period: From FY2020 to FY2024

Project overview: Technology Development Project for Social Implementation of Marine Biodegradable Plastics

https://www.nedo.go.jp/english/activities/activities_ZZJP_100168.html

*2 Polyester made by polycondensation of 1,4-butanediol and succinic acid.

*3 Polyester made by polycondensation of ethylene glycol and succinic acid.

*4 Copolyester with 3-hydroxybutyric and 3-hydroxyhexanoic acids introduced.

*5 Dicarboxylic acid compounds with a long carbon chain, i.e., sebacic acid with 10 carbon atoms and dodecanedioic acid with 12 carbon atoms in the project.