Longer lifetime of film light source thinner than paper(iOLED film light source)〜Hydrogen-bond induced novel electron injection mechanisms〜

Nippon Shokubai Co., Ltd. (Headquarters: Chuo-ku, Osaka City, President: Yujiro Goto, Securities No .: 4114.T) has developed novel electron injection*1 technology in collaboration with Japan Broadcasting Corporation (NHK) to enable further device life time of iOLED film light source, which is thinner than paper and highly flexible. iOLED is realized by both organic OLED materials which are stable to oxygen and moisture in the air and device technology (iOLED technology) collaborated with NHK.

However, in order to extend the device life time further, it was a problem to maintain high electron injection efficiencies for a long time even in the presence of oxygen and moisture. Then, we have developed novel electron injection technology for OLED that uses hydrogen bonding between two organic materials to overcome the problem. As a result, the iOLED film light source is able to achieve both higher air stability and longer device life time than before, and is expected to expand to undeveloped fields.

*1: injecting electrons from an electrode into an organic material

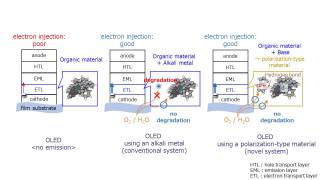

Alkali metals, which are used generally for the role of electron injection in the electron transport layer, show high electron injection efficiencies, but have poor environmental stability. The poor stability was the main factor of degradation in OLEDs. We have developed a polarization-type OLED material with an organic bases added instead of an alkali metal. Since this material has high air stability and high electron injection efficiencies due to polarization, high electron injection can be maintained for a long time even when an OLED is formed on a film that easily transmits oxygen and moisture. In addition, it was observed for the first time in the world that hydrogen bonds were formed by the addition of organic bases, and the resulting polarization played an important role in electron injection (Fig. 1). In the future, introducing this technology to iOLED film light sources will not only improve the properties of iOLED film light sources, such as fine tuning of emission color and the realization of long-lived ultrathin film light sources, but also be lower cost by simplifying the process.

The results of this research were published in Advanced Materials, on September 6.The iOLED film light source (Fig. 2) will be exhibited at our booth at the Chemical Materials Japan 2019, which will be held at Pacifico Yokohama on September 18 (Wednesday) and 19 (Thursday).

Nippon Shokubai continues to develop new products with creative and excellent technology, and strives to achieve its group mission of “TechnoAmenity― Providing affluence and comfort to people and society, with our unique technology.”

About NIPPON SHOKUBAI Co., Ltd.: Since 1941, Nippon Shokubai has grown up its business with unique catalyst technology. Nippon Shokubai has supplied, for example, ethylene oxide, acrylic acid, automobile catalysts, process catalysts and so on. Among all, our global market share of superabsorbent polymer is the largest in the world now. Nippon Shokubai is a global chemical company operating under its corporate mission “Providing affluence and comfort to people and society with our unique technology.” http://www.shokubai.co.jp/en/

【Contacts】

Investor & Public Relations Dept.,

NIPPON SHOKUBAI CO., LTD.

TEL: +81-3-3506-7605 E-mail: shokubai@n.shokubai.co.jp

Fig.1:Novel electron injection technology

Fig.1:Novel electron injection technology Fig2.The iOLED TM film light source

Fig2.The iOLED TM film light source