EPOMIN™ P-3000 Polyethyleneimine (PEI)

- Main Applications

Laminate anchor coating agents for paper, cloth, OPP and PET film, Heavy metal chelating agents, Metal plating additives, Foam retainers for fire extinguishers, Immobilized enzymes, Adhesives (for PVC sol flocculants, Epoxy resin crosslinkers), Ink adhesion enhancer, Water treatment (as coagulants)

Basic Information

High molecular weight hyper-branched polyethyleneimine

EPOMIN™ P-3000 has higher molecular weight and degree of branching than P-1050. It shows superior performance.

Examples of Applications

Promotes adhesion of extrusion laminate

Water treatment agents (Coagulants, Flocculants, Chelating agents)

Paper making agents (Fixing agents, Yield-improving agents)

Details of Functions

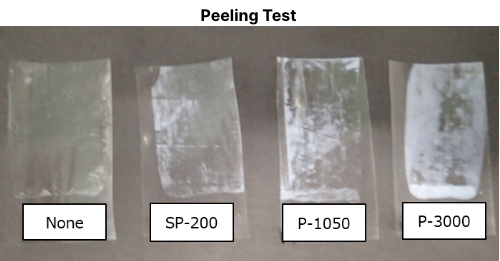

Adhesion

Highly adhesive with a wide range of combinations of base materials/resin.

| Base Materials | Resin | Blank | SP-200 | P-1050 | P-3000 |

|---|---|---|---|---|---|

| OPP Film | Acrylic Resin | Excellent | Excellent | Excellent | Excellent |

| Acrylic Emulsion | Poor | Good | Good | Excellent | |

| PVA Resin | Poor | Excellent | Excellent | Excellent | |

| PE Plate | Acrylic Resin | Poor | Good | Excellent | Excellent |

| Acrylic Emulsion | Poor | Poor | Good | Good | |

| PVA Resin | Poor | Poor | Good | Good |

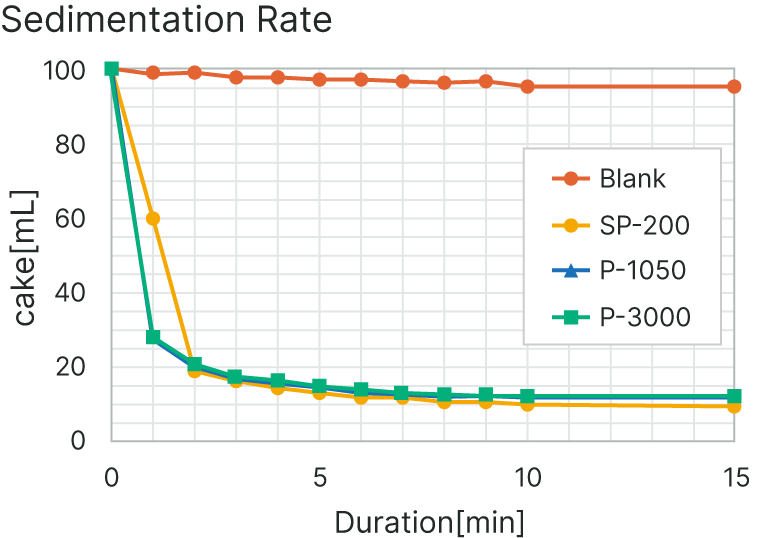

Flocculation

Shows high flocculating properties thanks to its high molecular weight.

| Composition | Water | 100 mL |

|---|---|---|

| Kaolin | 1g | |

| EPOMIN™ | 1 ppm/water |

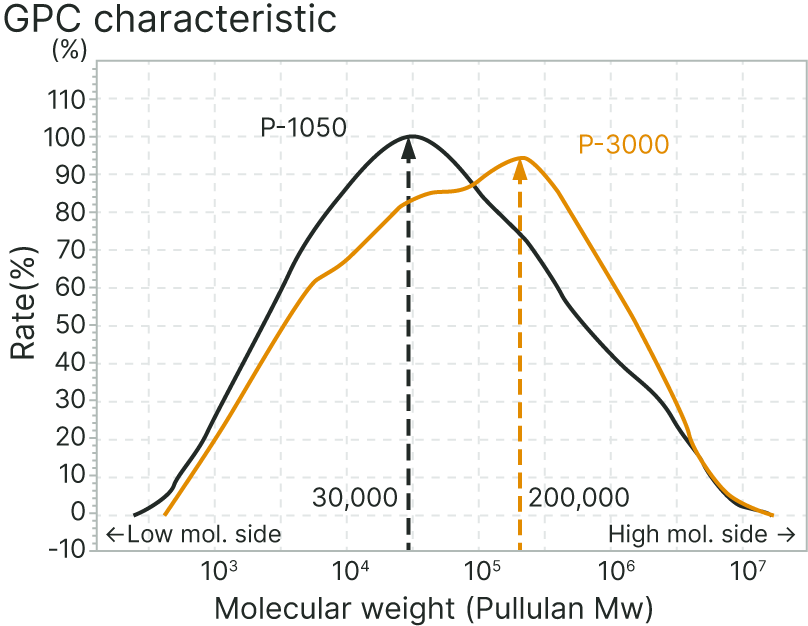

Comparison of Properties

| Properties | EPOMIN™ P-1050 | EPOMIN™ P-3000 |

|---|---|---|

| Number Average Molecular Weight (Mn) by Viscosity Method | 70,000 | 100,000 |

| GPC Characteristic*1 Weight Average Molecular Weight (Mw) Peak Top Molecular Weight High Polymer Region*2 (%, ≥ 30,000) | 350,000 30,000 55 | 450,000 200,000 70 |

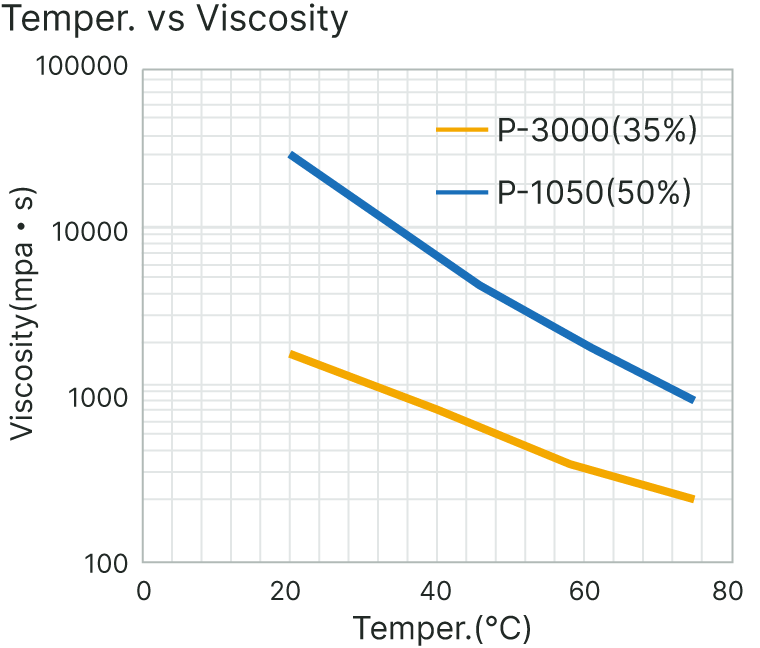

| Viscosity (mPa·s at 25°C) | 10,000~20,000 | 1,300 – 2,600 (on an as-is basis) |

| Resin Content (wt%) | 49~51 | 34~36 |

| pH (5% Aqueous Solution) | 10~12 | 10~12 |

| Appearance | Transparent, viscous liquid | |

| Solubility | Soluble in water and lower alcohol, Not easily soluble in toluene | |

| Amine Ratio (Primary:Secondary:Tertiary) 13CNMR Method | 25:50:25 | 30:40:30 |

| Specific Gravity | 1.08 | 1.05 |

| Amine Value (mmol/g-solid) | 18 | 18 |

| Freezing Point (°C) | <-15 | -10 |

| Decomposition Temperature (°C) DSC Method | 300 | 300 |

| CAS No. | 9002-98-6 (Aziridine homopolymer) | |

*1 : Molecular weight (Mw) according to the GPC method is the relative molecular weight for measured using Pullulan as the standard.

*2 : The high polymeric region (%)

means the content rate of polymers which Mw are minimum 30,000 (the origin of the high performance of P-3000) in the whole polymer.

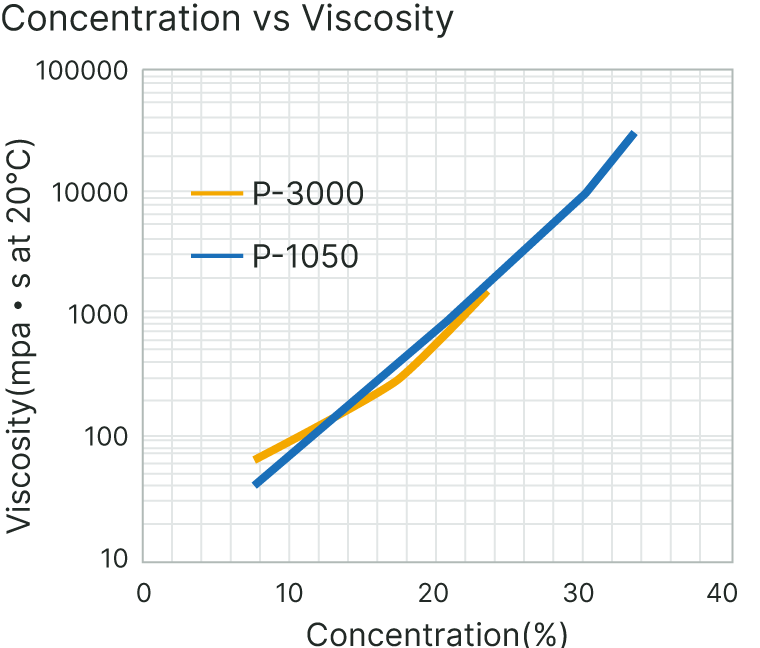

Viscosity

In the high concentration region, the viscosity is the same as that of P-1000 and handling properties do not easily deteriorate.

Catalog

Precautions

If the product is stored in high temperatures and comes into contact with the air (oxygen or carbon dioxide gas), it may deteriorate in quality such as coloring occurring. Please take care when storing the product, as it absorbs carbon dioxide gas in the air.

Applicable Materials

Suitable materials: Stainless steel, Synthetic resin (polyvinyl chloride (PVC), polyethylene (PE), polypropylene (PP), FRP, etc.); Unsuitable materials: Iron, Copper-based metals

Storage Conditions

Please avoid storing the product under the conditions of direct sunlight, rain, heat, and near flames. Please keep the containers sealed and store them in a cool and dark place when not in use. Product Safety information for this product is listed in the Chemical Products Safety Data Sheet (SDS). Please read it carefully before use.