Polyethyleneimine: EPOMIN™ Polyethyleneimine (PEI)

- Main Applications

Laminate anchor coating agents for paper, cloth, OPP and PET film, Heavy metal chelating agents, Metal plating additives, Foam retainers for fire extinguishers, Immobilized enzymes, Adhesives (for PVC sol flocculants, Epoxy resin crosslinkers), Ink adhesion enhancer, Water treatment (as coagulants)

- Applications

- Functions

Basic Information

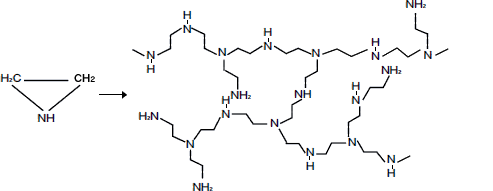

Polyethyleneimine (EPOMIN™) is a water-soluble polymer made by the polymerization of ethyleneimine. EPOMIN™ is not an entirely linear polymer; it has a highly-branched structure that contains primary, secondary, and tertiary amines. Its features are listed below.

- It is the highest cation-dense polymer in existence.

- It is a very high reactive polymer.

- It is a water-soluble polymer.

Manufacturing Method

Product Details

There are eight types of EPOMIN™ with different molecular weights (including at developmental stage). , each with a different molecular weight. Only high molecular weight types are diluted in water.

| Item Number | SP-003 | SP-006 | SP-012 | SP-018 | SP-200 | HM-2000 | P-1050 | P-3000* | |

|---|---|---|---|---|---|---|---|---|---|

| Molecular Weight | 300 | 600 | 1,200 | 1,800 | 10,000 | 30,000 | 70,000 | 100,000 | |

| Product

Specifications | Resin Content (wt%) | >98 | >98 | >98 | >98 | >98 | 93 – 95 | 50±2 | 35±1 |

| Viscosity

(mPa·s at 25°C) | 200 – 500 | 500 – 2,500 | 3,500 – 7,500 | 8,500 – 15,000 | 40,000 – 150,000 | 5,000~ 15,000 (50% aqueous solution) | 10,000 – 20,000 | 1,300 – 2,600 | |

| pH (5% aqueous solution) | 10~12 | ||||||||

| Appearance | Pale yellow, transparent liquid | Transparent, viscous liquid | |||||||

Features and Properties

High adhesion and absorption

The amino group forms hydrogen bonds with hydroxyl group, ionic bonds with carboxyl group, and covalent bonds with the aldehyde group and ketone group. EPOMIN™ also has polar group (amino group) and hydrophobic group (ethylene group) in its structure, which and enhances its bonding force with materials of different polarities. These comprehensive bonding forces of EPOMIN™ are utilized in fields such as adhesion, ink, paint, and pressure-sensitive adhesive agents.

High cationicity

EPOMIN™ exists as polycation in water, and it neutralizes and adsorbs all types of anionic materials. EPOMIN™ also chelates heavy metal ions. This highly cationic property of EPOMIN™ is utilized in fields such as paper manufacturing, water treatment, plating bath agents, dispersants, etc.

Highly Reactive

Because of its reactive primary and secondary amino group, EPOMIN™ easily reacts with epoxy, aldehyde, isocyanate compounds, and acid gases.This highly reactive property of EPOMIN™ is utilized in the modification of epoxy resins, aldehyde adsorbents and dye-fixing agents.

Examples of Applications

| Field | Applications | Recommended Products | Features |

|---|---|---|---|

| Paper Making and Processing | Neutral sizing agents for paper making chemicals | P-1050 | Neutralization and fixing of anion charging material, Yield-improving agent, Pitch controller, White water purification, Promotes the dispersion and fixing of ketene dimmers |

| Adhesives | Pressure sensitive adhesive | SP-200 P-1050 | Formulation in pressure sensitive adhesives to improving the cohesive force (adhesive retention power) |

| PVC sol adhesive | SP-018 SP-200 | Formulation in PVC to improve adhesion to base materials | |

| Water-based adhesive | SP-200 P-1050 | Formulation in EVA, poly vinyl acetate, PVA, and acrylic adhesives to improve adhesion | |

| Anchor coating agent for extrusion laminate | P-1050 | Improves adhesion of PE extrusion laminate/PET film, paper, OPP | |

| Anchor coating agent for gas barriers | P-1050 | Improves adhesion of PVA, EVOH/olefin film | |

| Release agent | RP-20 | Rear-side processing of various tapes | |

| Paint and Ink | Alcohol-based ink for film (Polyvinyl butyral-based ink) | SP-200 | Formulation in ink to improve adhesion with film |

| Water-based paint and ink (Acrylic-based emulsion) | SP-012 SP-018 | Formulation in acrylic-based emulsion to be quick-drying, adhesive, and water resistant | |

| Textiles | Fixing agent | P-1050 | Improves washing fastness and dyeing affinity |

| Functional textiles | P-1050 | Eliminates odors such as from tobacco, etc. in textiles | |

| Tire cord | P-1050 | Improves the adhesion of various cords/rubber | |

| Sizing agent for glass fibers | P-1050 | Lubricates glass fibers | |

| Fire retardant | P-1050 | Fixes phosphorus-based fire retardant | |

| Water Purification | Liquid clarifier | P-1050 | Detoxifies aldehyde water, Removes bleaching chlorine |

| Coagulant | P-1050 | Neutralizes surface charges, easily flocculates and separates between particles, improves sludge dehydration efficiency, Destroys emulsion | |

| Separation agent for bacterial cell flocculation | P-1050 | Neutralizes surface charges in bacterial cells, flocculates and separates bacterial cells | |

| Chelating agent | P-1050 | Removes heavy metal ions | |

| Gas Purification | Gas scavenger | P-1050 | Supported by filters to absorb CO2, NOx, SOx, CI2, and aldehydes in gas |

| Distributed field | Dispersant | SP-012 | Stably disperses ceramics, carbon black, coal, cement, metal powder, pigment, etc., and gives adhesion to base materials |

| Plating and Metal Surface Treatment | Metal plating bath agent Electroless plating solution | SP-006 | Provides luster to and smoothens Zn plating |

| Corrosion inhibitor for acid pickling Primary rust inhibitor | P-1050 | Adsorbs metals, and inhibits acid corrosion of the metal matrix | |

| Biotechnology | Immobilized enzyme, Microorganism immobilizing carrier | P-1050 | Immobilizes enzymes to inactive base materials, and used in bioprocesses; Immobilizes bacterial cells to inactive base materials, and used in cleansing water |

| Petroleum | Petroleum emulsion breaker Fluid loss agent | P-1050 | Neutralizes surface charges, and flocculates and separates between particles; Fluid loss agent for cement slurry used in wells |

| Antibacterial and Antiseptic | Antibacterial and bactericidal polymer | P-1050 | Makes Ag and Cu chelated complex that shows an antibacterial effect |

| Wood preservative, Cut flowers preservative | SP-018 | Makes Cu chelated complex that penetrates into wood and retains metals | |

| Other | Foam fire retardant | P-1050 | Improves foam retention, making it effective for use in oil fires |

| Microencapsulating agent | P-1050 | Uses its high reactivity to form a microencapsulated coating | |

| Electronic and conductive material | SP Series P-1050 | Polishing agent for solid electrolytes and semiconductors, Resist and patterning agent, Resist cleaning |

Please pay attention to existence of these intellectual property rights, and avoid the possible infringement of such rights.

Catalog

Precautions

Food Products

◆FDA publication circumstance of Polyethyleneimine

Polyethyleneimine having CAS No.9002-98-6 is published by the following 1), 2) and 3).

In addition, polyethyleneimine having CAS No.68130-97-2 is published by the following short-term work of 4).

1)Adhesives

Part 175 (Indirect food additives: Adhesive agents and coating components)

- 175.105: Adhesive agents (Lamination and sealing used in food packaging)

- 175.320: Resin coatings and polymer coatings for polyolefin films

2)Paperboard

Part 176 (Indirect food additives: Paper and paperboard components)

- 176.170: Components of paper and paperboard that have contact with aqueous and fatty food products (usage amount is 5 wt% max.)

- 176.180: Components of paper and paperboard that have contact with dry food products (usage amount is 5 wt% max.)

3)Food Packaging

Part 177 (Indirect food additives: Polymers)

- 177.1200: Food packaging cellophane (polyethyleneimine is recognized as a component of cellophane)

- 177.1400: Water-insoluble hydroxyethyl cellulose film (polyethyleneimine is recognized as a component of hydroxyethyl cellulose film)

4)Enzymes

Part 173 (Secondary direct food additives permitted in food for human consumption)

- 173.357: Fixing agents in the immobilization of enzyme preparations

Handling and Storage Precautions

1) Storage Stability

(SP Series, HM-2000)

- This product will keep stable for about one year when stored in a cool and dark place. However, if the product comes into contact with the air (oxygen), its quality may deteriorate such as coloring occurring or film forming on the surface.

- Please take care when storing the product, as it is highly hygroscopic, and absorbs carbon dioxide gas in the air.

(P-1050, P-3000)

- This product will keep stable for about one year when stored in a cool and dark place. However, if the product comes into contact with the air (oxygen), its quality may deteriorate such as coloring occurring.

- Please take care when storing the product, as it absorbs carbon dioxide gas in the air.

2) Heating of Containers

- The cans and drums used by Nippon Shokubai to ship EPOMIN™ have a synthetic resin coating. This coating film may peel off and the product may become colored if the containers are heated to high temperatures (minimum of 80°C) for a long period.

- If heating the product containers, please use warm water at a maximum temperature of 80°C.

3) Applicable Materials

■ Suitable materials

- Stainless steel

- Synthetic resin (polyvinyl chloride (PVC), polyethylene (PE), polypropylene (PP), etc.)

■ Unsuitable materials

- Iron materials such as soft iron (coloring due to rust)

Particularly when in aqueous solutions, the iron rust causes EPOMIN™ to harden. - Copper and copper-containing alloys such as brass (reaction to EPOMIN™ generates blue-green colored complex salt)

4) Storage

- Please avoid storing the product under the condition of direct sunlight and rain.

- Please store the product in places with impermeable floor surfaces.

- Please reseal and store the product after use.

- Please try to store the product in a cool and dark place.