In development Low Dielectric Insulating Coating Materials: RX-8-SP/SA/SB Series

- Main Applications

Materials for use in electronics, Semiconductor packaging and in-vehicle parts, Optical materials

- Applications

- Functions

Features and Properties

- “RX-8-SP/SA/SB Series” contains novel thermosetting polymers different from PFAS or polyimide moieties.

- The thermoset coating films exhibit Excellent Flexibility, Chemical Resistance, Heat Resistance, Low Dielectric Properties & Insulating Properties.

- The product specification is adjustable with variation for end-use applications, and we contribute to helping the customers designing of advanced products.

Details of Functions

Example of Chemical Properties

Table 1. Chemical properties of the RX-8-SP/SA/SB Series

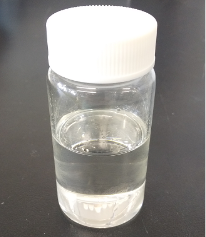

| Item | Features |

|---|---|

| Appearance | Colorless, transparent, and highly viscous liquid |

| Solid Content | Maximum of 70 wt% |

| Solvents | Higher alcohol, hydrocarbon, high boiling point ether, etc. |

| Toxicity | Does not contain perfluoroalkyl groups |

| Coating Conditions | Drying: 100°C for 30 minutes

Curing: 200 – 220°C for 60 minutes |

Physical Properties of Cured Coating Film

Table 2. Physical properties of cured coating film with the RX-8-SP/SA/SB Series

| Item | Features | Compliance Standards | |

|---|---|---|---|

| Appearance of Coating Film

(Visual) | Colorless | Proprietary Standards | |

| Coating Film Transparency

(Visible light range) | ≥ 85% | ASTM D1746 | |

| Insulation Breakdown Voltage

(Film thickness: 10 μm) | 2KV | ASTM D149 | |

| Dielectric Properties | ε | 2.4 (1 GHz)

2.3 (10 GHz) | ASTM D2520 |

| tan δ | ≤ 0.01 (1 GHz)

≤ 0.01 (10 GHz) | ASTM D2520 | |

| Bending Workability | No peeling off from the copper adhesive surface | JIS K 5600-5-1

(ø5 Mandrel Test) | |

| Adhesion | No peeling off from various substrate

(Cu, Si, SiO2 etc. ) | JIS K 5600

(Cross-cut Test) | |

| Heat Resistance

(Maintains 95% weight) | 220°C for 500 hours (in the air)

430°C for 2 hours (inert atmosphere) | Proprietary Standards

(Weight loss) | |

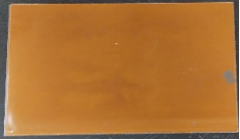

Fig. 2. Examples of films cured using RX-8-SP

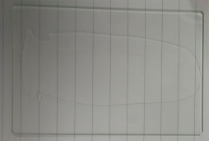

Mechanical Properties of Cured Coating Film

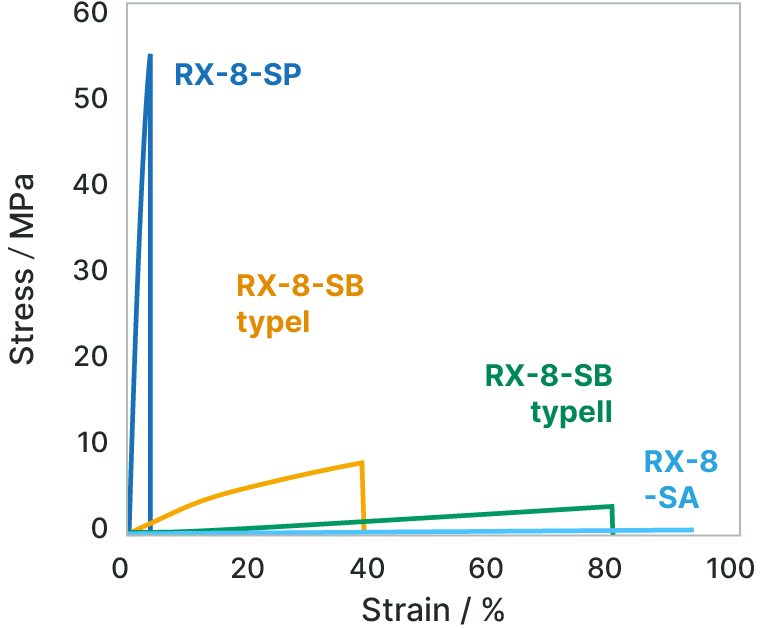

Fig. 3. Tensile test of cured coating film with the RX-8-SP/SA/SB Series

Measurement Conditions

Measurement temperature: 25°C, Distance between gauges: 30 mm, Tensile

Speed: 5 mm/minute, Film thickness: 100 μm

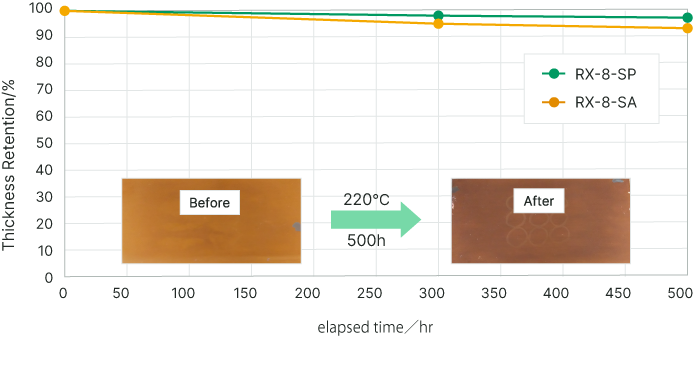

Examples of Heat Resistance Evaluation

Fig. 4. Heat resistant test of cured coating film with the RX-8-SP/SA Series (Temperature: 220℃, substrate: Copper, Film thickness: 20 μm)