Aminoethylated Acrylic Polymer: POLYMENT™ Aminoethylated Acrylic Polymer

- Main Applications

Primers for various base materials (for OPP, PET, PVC films, paper, metals, etc.), paints and coatings, adhesives

- Applications

- Functions

Basic Information

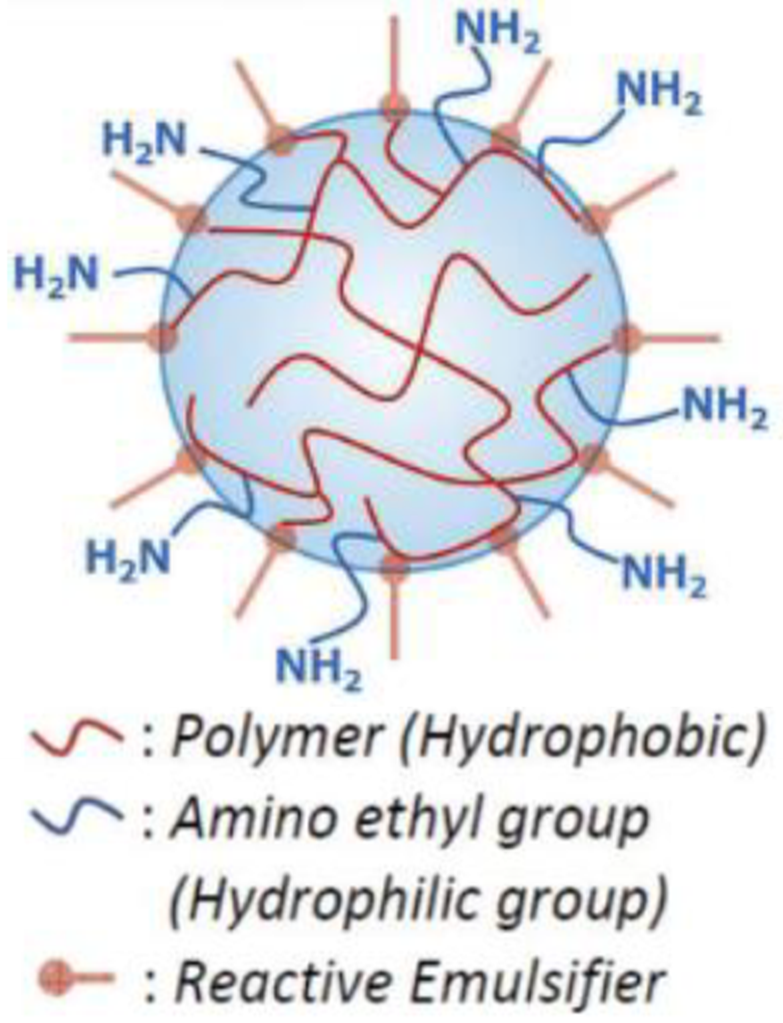

POLYMENT™ is an acrylic polymer containing primary amino groups due to the grafting of polyethyleneimine onto its side chains. POLYMENT™ is a polyacrylamine that has the features of both polyethyleneimine and acrylic polymer. POLYMENT™ exhibits high reactivities thanks to its primary amino groups and superior adhesiveness to various base materials.

Cationic acrylic polymers are generally known as being tertiary amine and quaternary ammonium polymers, such as dimethylaminoethyl acrylate or dimethylaminoethyl methacrylate polymer. POLYMENT™ is the only cationic acrylic polymer with primary amine in the world (based on an in-house survey by STN on December 11, 2019).

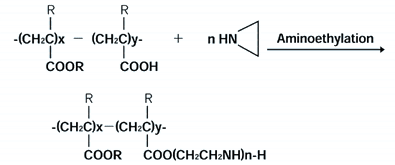

Manufacturing Method

Using the reactivity of ethyleneimine and carboxyl groups, acrylic acid copolymers can be easily converted to acrylic polymers with primary amines.

Features and Properties

Because it contains primary amino groups, this resin exhibits excellent adhesion to various substrates such as plastics and metals, as well as high reactivity with epoxy resins and other materials. Taking advantage of these properties, it is used in adhesives for dissimilar materials and as anchor coat agents.

- Amino group-derived properties (similar to Epomin):

Adhesion, Reactivity, Cationic nature - Acrylic backbone-derived properties:

Film-forming ability, Weatherability, Film hardness

Examples of substrates with excellent adhesion

- Metals (Zn, Fe, Al, Cu, etc.)

- Glass

- Resins (Acrylic, Styrene, ABS, Epoxy, OPP, PVF, ETFE, PVC, etc.)

- Concrete

- Slate

Overview and features of each series:

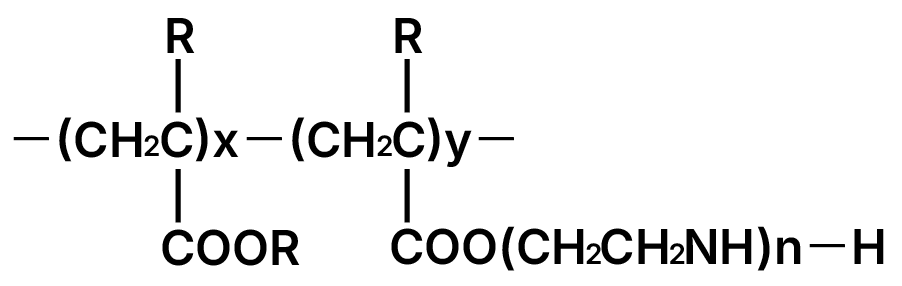

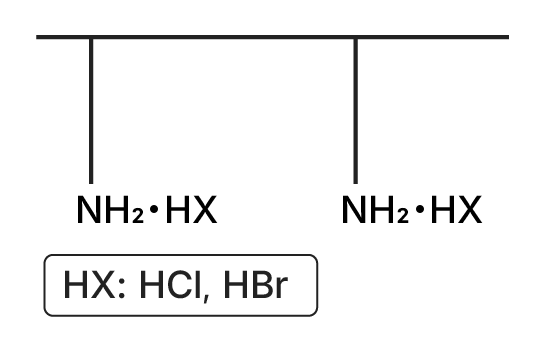

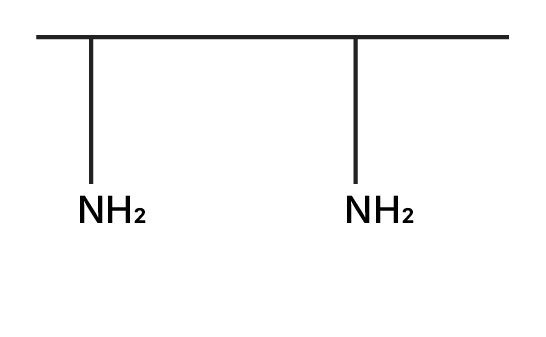

The POLYMENT™ series is classified into three types based on form: (1) Water-dispersible resins, dispersed in water, (2) water-dilutable resins which can be diluted with water by neutralizing the amino groups, and (3) solvent-based resins synthesized in organic solvents.

Since all types contain primary amino groups, they exhibit excellent adhesion to substrates such as plastics and metals, and high reactivity with epoxy resins.

| Item | NK-100PM | NK-200PM | NK-350 | NK-380 | KX-EK-100R* | KX-EK-350R* |

|---|---|---|---|---|---|---|

| Type | Water dilutable | Solvent based | Water dispersed | |||

| Structure |  |  |  | |||

| Tg(℃) | 13 | 16 | 40 | 100 | ─ | ─ |

| Amine Value (mmol/g-solid) | 2.2-2.9 | 2.2-2.9 | 0.6-1.0 | 0.7-1.3 | 0.5-1.0 (calc. 2.2) | 0.2-0.33 (calc. 1.1) |

| Neutralizing acid | HCl | HCl, HBr | ─ | ─ | ─ | ─ |

| Solvent | Propylene glycol monomethyl ether/Water | Toluene /IPA | Toluene/MIBK | Water(Emulsion) | ||

| Resin content(%) | 48-52 | 55-57 | 33-37 | 29-31 | 29-31 | 29-31 |

| Characteristics | ・Uniformly soluble in water ・Emulsifies epoxy resins for long pot life and reduced solvent use ・Cured films show excellent room-temperature curing and weather resistance | ・Prevention of plasticizer migration from PVC ・Water resistance | ・VOC free ・Ames negative(EK-100R) ・Long pot life ・Water resistance | |||

| Applications | ・Primer for olefin films ・Water based for floor paints ・Enhances adhesion of water-based adhesives (e.g., EVA) | •Primer for pressuresensitive adhesive tape •Adhesive promoting agents and primer for films •Adhesives of fluorine film with Steel (NK-350) •Antimigration agent for PVC film (NK-380) | ・Primer for paper and films ・Adhesion promoter for water-based adhesives such as EVA ・Adhesives and binders for building materials and flooring ・Adhesion promoter / crosslinker for coatings | |||

▼Click here for an introduction video on Water-based POLYMENT™

Functions

Adhesion

We compared the adhesion performance of POLYMENT™ NK-350 by modifying its primary amino groups with various substituents. Primary amino groups exhibit excellent adhesion to a wide range of materials.

Film Adhesion (Forced peel test using acrylic adhesive tape)

| Functional Group | Primary Amino Group | Carboxyl Group | Amide Group | Hydroxyl Group | Tertiary Amino Group | Ester Group |

|---|---|---|---|---|---|---|

| OPP | 〇 | × | △ | ○ | × | △ |

| PVC | 〇 | ○ | ○ | ○ | ○ | ○ |

| PVF | 〇 | ○ | ○ | ○ | ○ | × |

| ETFE | 〇 | △ | × | × | ○ | × |

| AI foil | 〇 | ○ | × | × | △ | × |

Substrate Adhesion (Cross-cut test)

It is evaluated by counting the number of squares that remain intact out of 100.

| Functional Group | Primary Amino Group | Carboxyl Group | Amide Group | Hydroxyl Group | Tertiary Amino Group | Ester Group |

|---|---|---|---|---|---|---|

| Zinc | 〇 | ○ | ○ | ○ | ○ | △ |

| Iron | 〇 | × | × | × | ○ | × |

| Aluminum | 〇 | × | × | × | × | × |

| Glass | 〇 | △ | × | × | × | × |

| Acrylic resin | 〇 | ○ | ○ | ○ | ○ | ○ |

| Styrene | 〇 | × | ○ | ○ | ○ | ○ |

| ABS | 〇 | ○ | ○ | × | × | × |

| Epoxy resin | 〇 | △ | ○ | × | × | × |

| Concrete | 〇 | ○ | ○ | ○ | ○ | ○ |

| Slate | 〇 | ○ | ○ | ○ | ○ | ○ |

After coating to a dry thickness of 30 μm, dried at room temperature for 2 days.

Prevention of Plasticizer Migration / Stain Resistance

| Treatment Agent | POLYMENT™ NK-380 | None | Conventional acrylic resin | |

|---|---|---|---|---|

| 5kg 70℃ 24h Plasticizer migration (mg) | 3 | 38 | 13 | |

| 2kg 50℃ 24h Stain resistance | 〇 | × | △ | |

| 180˚peel strength (kg/25mm) | Initial | 2.5 | 2.5 | 2.5 |

| after 5days at 20℃ | 2.5 | 2.3 | 2.5 | |

| after 5days at 80℃ | 1.8 | 0.3 | 0.9 | |

After coating a 1 μm dry film on a soft PVC sheet, dried at 100–120℃ for 2 minutes.

Performance of Water-based POLYMENT™ KX-EK-100R and KX-EK-350R (in development)

Film Water Resistance / Solvent Resistance

Resistance is improved by crosslinking with epoxy compounds

| Additive | NK-100PM | KX-EK-100R | KX-EK-350R | |||

|---|---|---|---|---|---|---|

| Water | Acetone | Water | Acetone | Water | Acetone | |

| None | × | × | △ | △ | ◎ | ○ |

| BisA type epoxy emulsion | △ | △ | △ | ○ | ◎ | ◎ |

| Glycerol polyglycidyl ether | ○ | ○ | ○ | ○ | ◎ | ◎ |

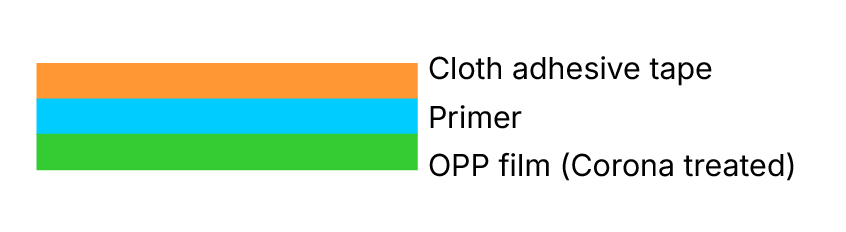

Adhesion to OPP Film

Exhibits good adhesion both before and after water immersion.

| NK-100PM | KX-EK-100R | KX-EK-350R | ||||

|---|---|---|---|---|---|---|

| Initial | After water immersion | Initial | After water immersion | Initial | After water immersion | |

| 180˚peel strength (N/15mm) | 5.8 | – | 8.4 | 8.4 | 9.7 | 9.6 |

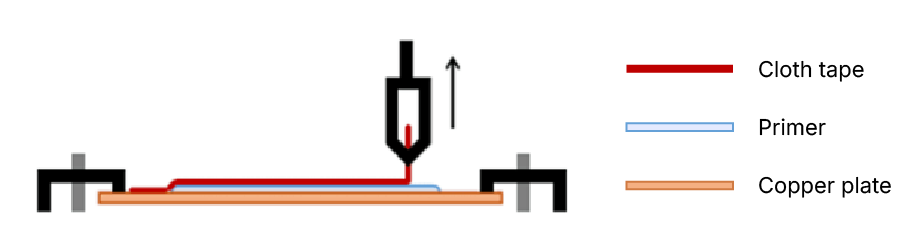

Adhesion to Copper Plate

The amino side chains coordinate with metal surfaces, providing good adhesion.

| None | KX-EK-100R | KX-EK-350R | |||

|---|---|---|---|---|---|

| Before EI addition | After EI addition | Before EI addition | After EI addition | ||

| 90˚peel strength (N/15mm) | 6.3 | 5.3 | 10.3 | 3.5 | 7.9 |

Examples of Applications

.jpg)

.jpg)

.jpg)

-1.jpg)