Ultraviolet Absorbent Functional Resins: HALSHYBRID™ UV-G Special acrylic resin

- Main Applications

Ultraviolet absorbent functional resins

- Applications

- Functions

Basic Information

HALSHYBRID™ UV-G is the product name of acrylic resins with UV absorbing groups and UV stabilizing groups (HALS) chemically incorporated into the resin skeleton.

HALS is an abbreviation for Hindered-Amine Light Stabilizer.

The degradation of polymers is generally due to radicals, active oxygen and other substances generated by UV rays. HALS inactivates those substances.

By continuously absorbing and blocking out UV rays for long periods of time, HALSHYBRID™ UV-G reduces the photo-degradation of base materials (coating surfaces) and improves the weatherability of coatings.

Generally, UV rays have wavelengths in the range of 190 – 400 nm, and are divided into three wavelength groups of UV-A, UV-B, and UV-C starting from the longest wavelength.UV-A and UV-B wavelengths are particularly damaging in various ways to coating films.

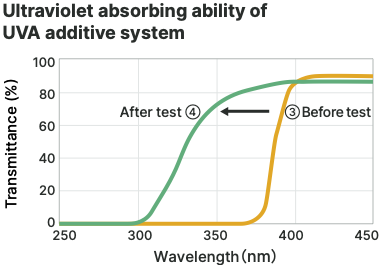

Ultraviolet absorbent (UVA) additives have been traditionally used to combat UV rays. However, UVA tends to bleed out during long periods of use, which reduces the effect of blocking out UV rays.

HALSHYBRID™ UV-G are acrylic resins with ultraviolet (UV) absorbent functional groups chemically incorporated into the resin skeleton; this means there is no usual concern about the UVA bleeding out, as the effect of blocking out UV rays can be sustained for long periods of time.

Features and Properties

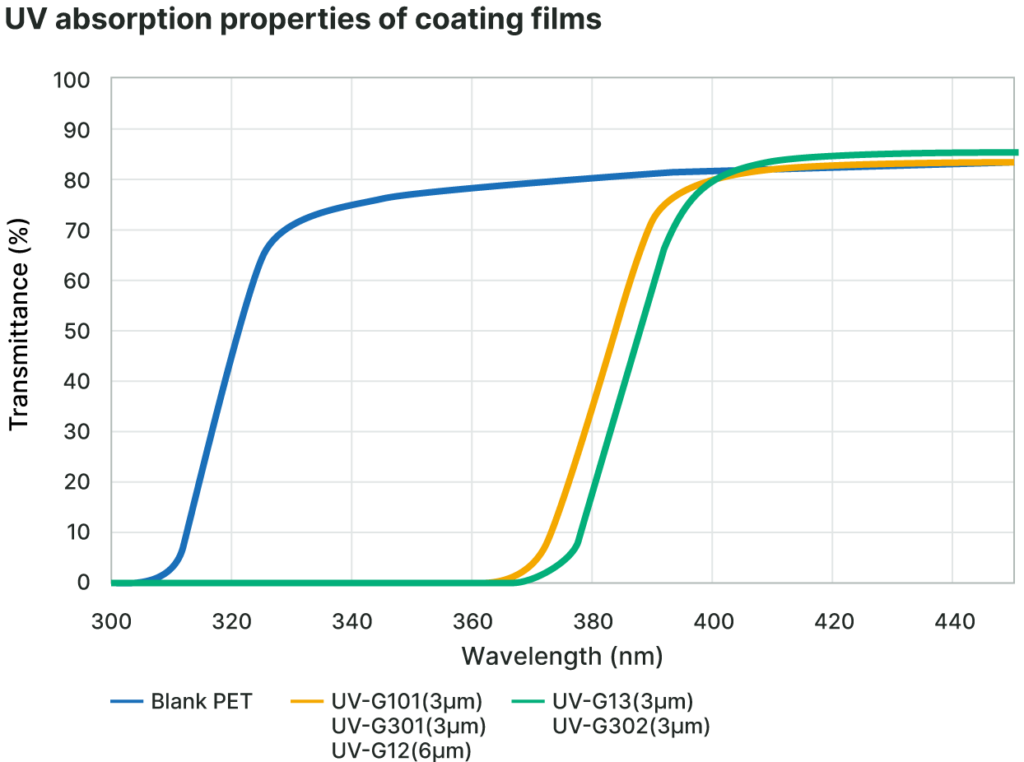

Cuts out a wide range of UV rays

HALSHYBRID™ UV-G products use optimal UV absorbing groups, which enables them to cut out almost 100% of wavelengths of around 370 nm or less in PET base materials of thin coating films (3 – 6 μm).

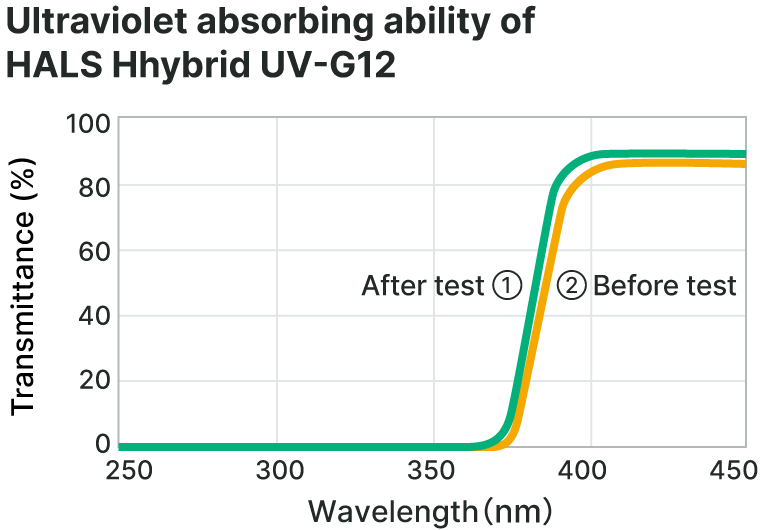

Long-lasting and continuous absorption

HALSHYBRID™ UV-G are coating materials with UV absorbing groups chemically incorporated into the resin skeleton; this means there is no usual concern about the UVA bleeding out, as the effect of blocking out UV rays can be sustained for long periods of time.

Excellent light transmittance

HALSHYBRID™ UV-G products have the same light transmittance as that of the visible light transmittance of base materials in thin film coatings, so they do not diminish the visible light transparency of film base materials.

There is also virtually no visible coloring in materials coated with HALSHYBRID™ UV-G.

HALSHYBRID™ UV-G can be diluted in a wide range of solvents.

HALSHYBRID™ UV-G are solvent-type products that can be diluted in a wide range of solvents. They dissolve exceptionally well in aromatic solvents such as ester solvents, toluene, and xylene, etc., and can be diluted at a high ratio.

HALSHYBRID™ UV-G can also be diluted in alcohol and high polarity ketones, even though they have a limited dilution ratio.

Examples of Applications

Base Materials

Experienced in handling PET, polyolefin and other film base materials, as well as polycarbonate and acrylic materials, etc.

Applications

Building materials and top coat materials, Window films, Agriculture films, Preventing discoloration of outdoor advertisements, Optical films, Gravure ink, etc.

Suitable for protecting the base coat and improving the weatherability of the base materials listed above.

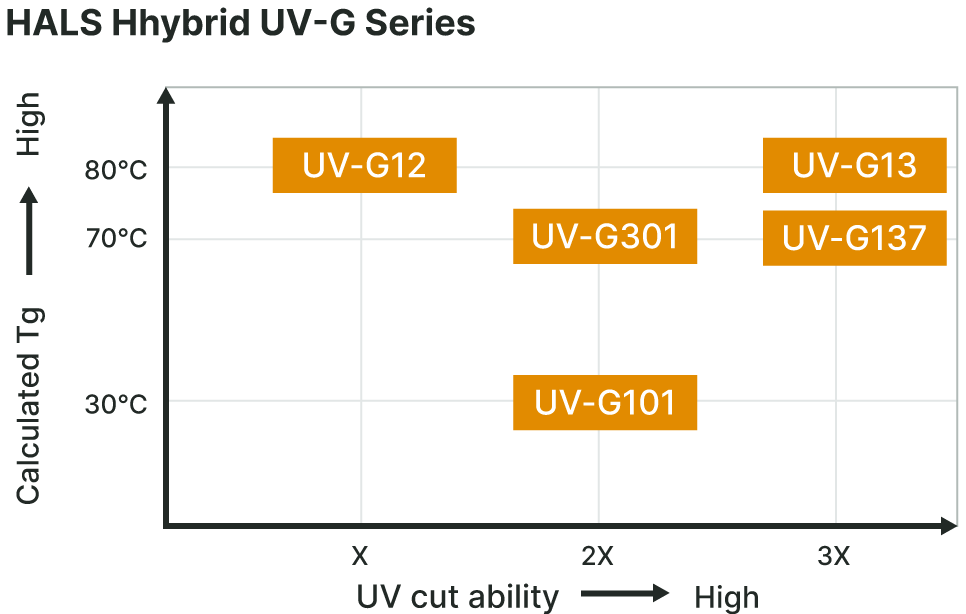

Lineup

Thermoplastic type (One-pack ordinary drying solvent)

The solvent is volatilized after coating is applied to the base materials, which enables a durable coating film to form.

Thermosetting type (Two-pack thermosetting solvent)

When combined with melamine-based curing agents in addition to polyisocyanates, this coating agent forms a crosslinked coating film that can improve the physical properties of coating films.

Depending on the type of curing agent and combination amount, the HALSHYBRID UV-G series can improve the properties of base materials such as adhesion, heat resistance, water resistance, and solvent resistance.

*<Combination example of polyisocyanate>

Polyisocyanate (g) = HALSHYBRID UV-G series (g) × (Hydroxyl group value of HALSHYBRID UV-G series/Isocyanate content of polyisocyanate (%)) × (42/561) × R

* R = NCO/OH (chemical equivalent ratio)

Please consider the optimal type of curing agent and combination amount, drying conditions, and other requirements in accordance with how you will use the product.