Electrolyte Sheets for Solid Oxide Fuel Cells (SOFC) Electrolyte sheets for solid oxide fuel cells (SOFC)

- Applications

- Functions

Basic Information

Fuel cells are a type of power generator that produces electrical energy from an electrochemical reaction of hydrogen with oxygen.

These include solid oxide fuel cells (SOFC), which are highly efficient in power generation and are expected to rapidly spread in the near future as next-generation, dispersion-type clean energy systems.

Nippon Shokubai is able to mass produce these zirconia sheets using our proprietary ceramic powder processing technology and ceramic firing technology. Our extensive product lineup and custom-made products are highly rated by SOFC manufacturers worldwide.

We will continue working on spreading and further improving the performance of SOFC through these products, which are backed by low-cost mass production technologies and high-quality control technologies.

Electrolyte Sheets

Present Status

Commercial Production

Location: Japan

Features

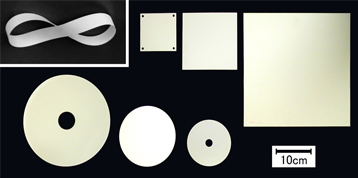

High Planarity

High Ionic Conductivity

High Mechanical Strength

Customized Shape

Controlled Surface Roughness

Product List

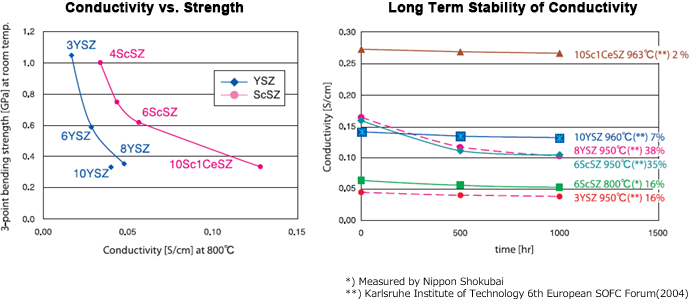

Technical data

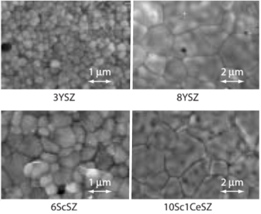

| type | 3YSZ | 8YSZ | 6ScSZ | 10Sc1CeSZ |

|---|---|---|---|---|

| Dopant, Content (mol%) | Yttria, 3% | Yttria, 8% | Scandia, 6% | Scandia 10%, Ceria, 1% |

| Crystal Structure | Tetragonal | Cubic | Tetragonal | Cubic |

| Relative Density | ›99.6% | ›99.6% | ›99.6% | ›99.6% |

| Warp | ‹50μm/inch | |||

| 3-point Bending Strength | 1.1GPa | 0.35GPa | 0.62GPa | 0.33GPa |

| Coefficient of Thermal Expansion (30-1000℃) | 10.9 ppm / K | 10.7 ppm / K | 10.7 ppm / K | 10.5 ppm / K |

| Conductivity (800℃) | 0.016 S/cm | 0.047 S/cm | 0.056 S/cm | 0.12 S/cm |

| Surface Roughness | On customer’s request | |||

| Size | Button~1,000cm2 | |||

| Thickness | 0.05 – 0.3mm | |||

Typical Electrolyte Surface(SEM)

Performance