ACRYCURE™ HD Acrylic resin for Thermal Interface Materials (TIM)

- Main Applications

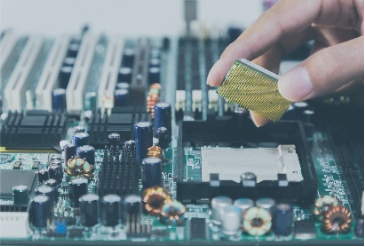

TIM Resin for Lithium-ion battery and Electronic devices, etc

- Applications

- Functions

Basic Information

| Appearance | Light yellow transparent liquid |

|---|---|

| Nonvolatile*1 | 50±1 wt% |

| Viscosity | 150 ±50 mPa·s at 25°C |

Features and Properties

- Siloxane-free

- Low-viscosity resins that have good compatibility with fillers

- Easy to handle

- Good flexibility

Examples of Applications

TIM Resin for Lithium-ion battery and Electronic devices, etc

Examples of Use

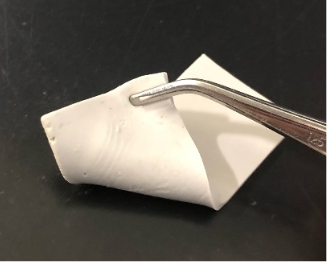

The photograph of a cured resin sheet made with ACRYCURE™ HD

Details of Functions

Properties

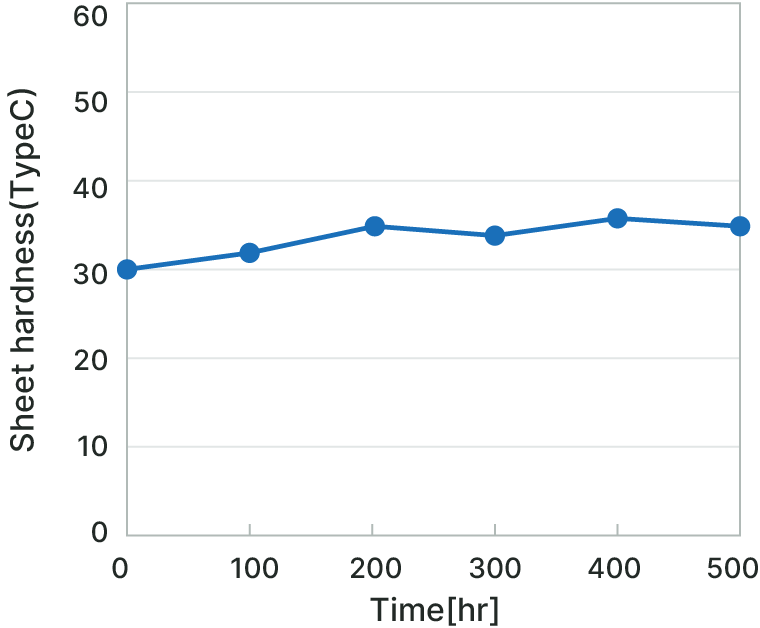

1) Sheet hardness

The good flexibility and good heat resistance of ACRYCURE™ HD provide flexible thermal dissipation materials.

Sheet hardness Heat-resistance (110℃) curve of TIM sheet Good heat-resistance!

Sheet composition

ACRYCURE™ HD : Alumina : Cross-linking agent : Curing agent = 100 : 400 : 0.07 : 1

Curing conditions: 90°C/30 min

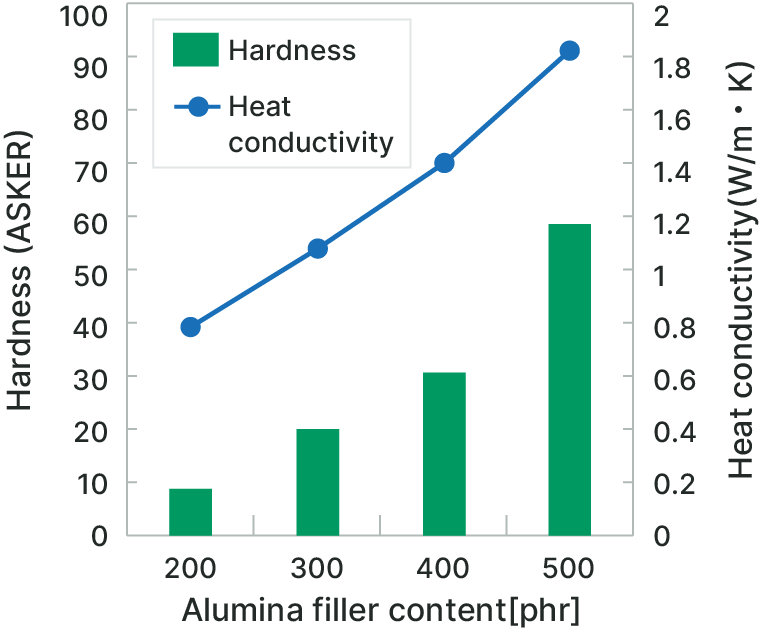

2) Easy design for thermal conductivity and hardness!

With the low viscosity and high compatibility with heat dissipation fillers of ACRYCURE™ HD, it is possible to fill heat dissipation fillers in high amounts and create heat dissipation sheets with high heat conductivity. It is also possible to maintain flexibility in heat dissipation sheets, even when filled in high amounts with heat dissipation fillers.

Sheet composition

ACRYCURE™ HD : Alumina : Cross-linking agent : Curing agent = 100 : 400 : 0.07 : 1

Curing conditions: 90°C/30 min

Heat conductivity measuring method: Hot Wire Method (JIS R2616)

Sheet thickness: 3 mm