De-NOx Catalyst De-NOx Catalyst

- Applications

- Functions

Basic Information

Experience and trust built over many years: Since 1978, Nippon Shokubai has been meeting the needs of customers with our commitment to uncompromisingly supplying high-quality, high-performance, and highly-durable De-NOx catalysts, backed by extensive experience and proven results in delivery (*).

We deliver optimal catalysts selected and designed in accordance with your requirements such as exhaust gas properties and outlet NOx.

(*) Power plant boilers fired by coal, oil and gas, waste incinerators, private power generation engines, firing furnaces, heating furnaces and other such facilities nationwide.

Features and Properties

With our proprietary titania-based composite materials and advanced manufacturing technologies, we are able to achieve a good balance of the following features.

Catalyst Performance

- High NOx removal rate and low ammonia slip

- Low SO2 → SO3 conversion rate (Prevents troubles in catalyst downstream equipment caused by acid ammonium sulfates.)

Highly durable (Long cycle life)

- High crush strength and abrasion resistant strength (abrasion of catalyst end surfaces and inner surface)

- Excellent resistance to poisoning, heat sintering, and clogging

Wide temperature range

- 160~450℃

Product Details

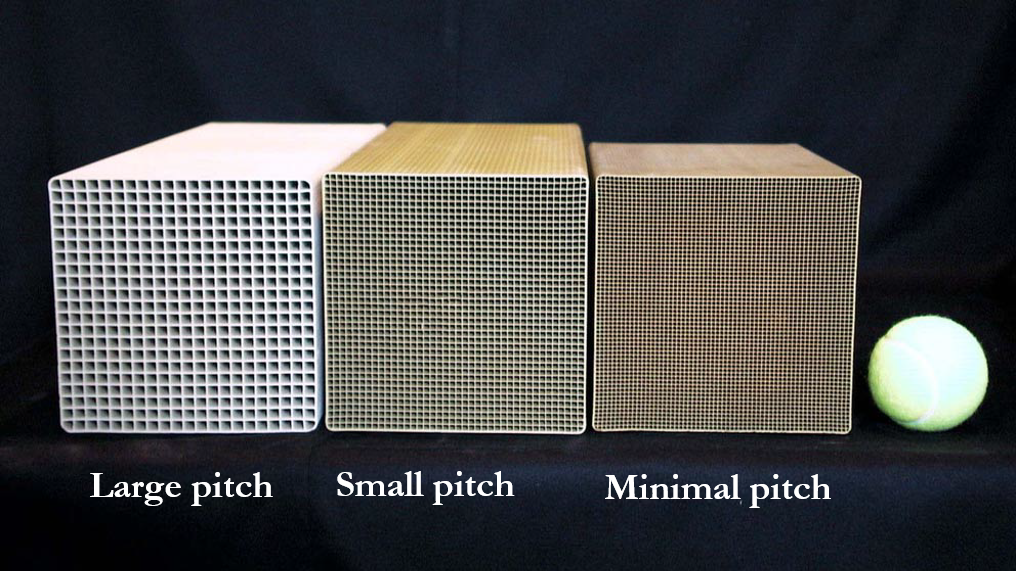

Honeycomb Shape

We can design an optimal number of cells, opening, and catalyst volume for each order.

Face Dimensions

- 150 mm × 150 mm

Length

- Maximum 1,060 mm

Typical examples

| Number of Cells (individual) | 15×15 | 20 × 20 | 21×21 | 25 × 25 | 30 × 30 | 35 × 35 | 40 × 40 | 45×45 | |

|---|---|---|---|---|---|---|---|---|---|

| Pitch (mm) | 9.80 | 7.35 | 7.00 | 5.95 | 4.95 | 4.25 | 3.70 | 3.30 | |

| Opening (mm) | 8.50 | 6.35 | 6.00 | 5.05 | 4.15 | 3.65 | 3.20 | 2.90 | |

| Inner Wall Thickness (mm) | 1.3 | 1.0 | 1.0 | 0.9 | 0.8 | 0.6 | 0.5 | 0.4 | |

| Geometric Surface (m²/m³) | 340 | 451 | 470 | 561 | 664 | 794 | 910 | 1044 | |

| Open Area (%) | 72 | 71 | 71 | 71 | 69 | 72 | 72 | 76 | |

| Custom Made Selection by Fuel | Coal (High Dust) | ● | ● | ● | ● | ||||

| Coal (Low Dust) | ● | ● | ● | ● | ● | ● | |||

| Oil | ● | ● | ● | ● | ● | ● | |||

| Gas | ● | ● | ● | ||||||