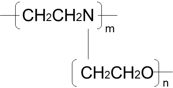

Polyethyleneimine Ethoxylate Polyethyleneimine Ethoxylate (PN-100)

- Main Applications

Raw material for various detergents, Papermaking agents (deinking, pitch control), Pigment dispersant, Water treatment agents (scale inhibitor), Abrasive grains dispersant, Plating additives

- Applications

- Functions

Basic Information

| Chemical Structure |  |

|---|---|

| CAS No. | 68130-99-4 |

| Appearance | Light brown, viscous liquid |

| Solid Content | 80% |

| Viscosity | ≦700 mPa・s(30℃) |

| Molecular Weight | 13,000 |

| Specific Gravity | 1.128 g/ml(30℃) |

| pH | 8-11 (1% aq.) |

Product Details

Polyethyleneimine ethoxylate is a non-ionic and water-soluble polymer, with various features as listed below. It has a wide range of applications and is suitable for use in various fields.

- High dispersibility of various types of particles

- Booster for anionic surfactants (lowering CMC, promoting adsorption)

- Coordination adsorption capability to metal surfaces

- High solubility in many kinds of solvents

- High compatibility with various types of surfactants

- Low effect on viscosity due to its highly-branched structure

Examples of Applications

| Fields | Applications | Features of Polyethyleneimine Ethoxylate (PN-100) |

|---|---|---|

| Detergent | Raw material for detergents | Booster for anionic surfactants (lowering CMC, promoting adsorption) Improving anti-redeposition ability (Dirt dispersion, Cloth protection) Synergy with enzymes, Improving the stability of enzymes Improving cleaning performance (detergency) High compatibility (PN-100 can be used in concentrated detergent) |

| Paper Making | Deinking agent Pitch control agent | Improving deinking efficiency, Anti-redeposition ability Adsorption to pitch, Improving dispersibility |

| Water treatment | Scale inhibitor | Adsorption to silica scale, Improving dispersibility |

| Paint, Ink | Pigment dispersant | Adsorption to anionic pigment, Improving dispersibility |

| Semiconductors | Abrasive grains dispersant for CMP (Chemical Mechanical Polishing) | Adsorption to silica abrasive grains, Improving dispersibility |

| Surface Treatment | Plating additives | Adsorption to metal surfaces, Plating inhibition |

The applications listed above may have intellectual property rights (including patents and their applications) owned by third parties.

Please pay attention to existence of these intellectual property rights, and avoid the possible infringement of such rights.

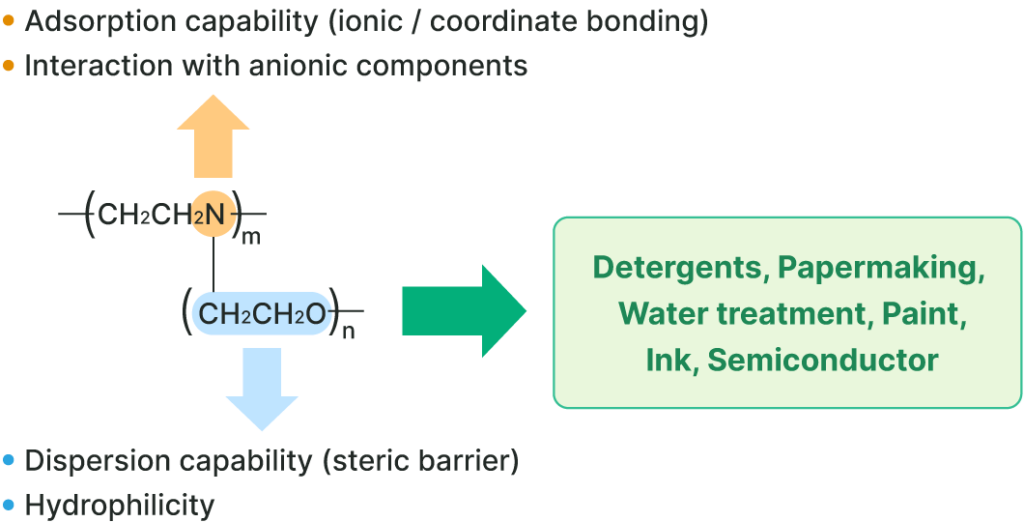

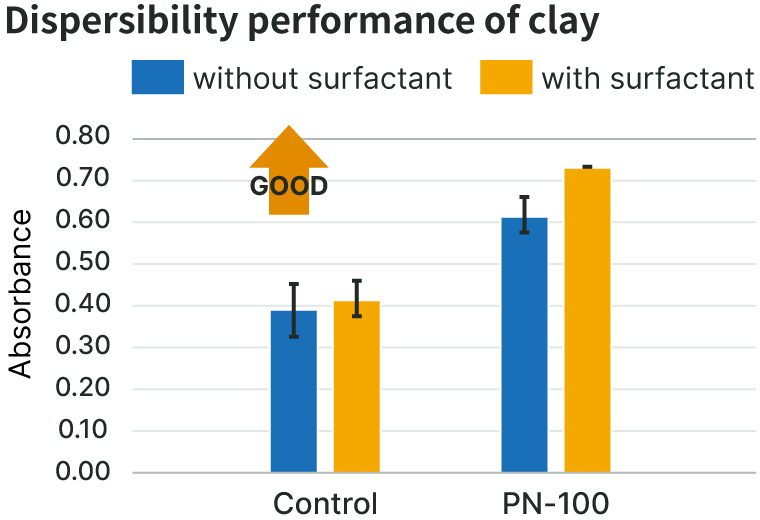

<Dispersibility of Particles>

PN-100 has high dispersibility of various types of particles.

For example, below are charts showing the dispersibility of natural clay and talc (magnesium silicate).

Evaluation Method

Clay water containing a predetermined amount of natural clay, surfactants and polymers is prepared and stirred.

The clay water is transferred to a test tube, and left to stand for the prescribed time. Then the absorbance is measured.

Evaluation Method

Surfactant (LAS): 0 or 1,250 ppm, Polymer: 40 ppm, Water hardness: 15 dH, Temperature: 25°C

*Surfactant (LAS): Linear Alkylbenzene Sulfonates

Evaluation Method

Talc particle water containing a predetermined amount of talc and polymers is prepared and stirred.

The talc water is transferred to a test tube and shaken for even dispersion, and left to stand for a predetermined time.

Then the absorbance is measured.

Evaluation Method

Talc: 500 ppm, Polymer: 10 ppm, Ca concentration: 200 ppm, Temperature: 25°C

<Booster for Anionic Surfactants>

Adding a small amount of PN-100 to anionic surfactant solution can improve the interfacial properties of anionic surfactants. This effect helps to reduce the usage amount of surfactants and improve their performance.

| CMC (mmol/dm³) Critical Micelle Concentration | Molecular Occupied Area (nm²) Area Occupied by One Surfactant Molecule | ΔG ads kJ/mol Ease of Adsorption | |

|---|---|---|---|

| LAS | 1.19 | 1.16 | -59.4 |

| LAS/Sodium polyacrylate | 1.10 | 0.76 | -35.0 |

| LAS/PN-100 | 0.92 | 2.30 | -84.7 |

Evaluation Method

The Wilhelmy method is used to measure the surface tension at various surfactant concentrations.

Evaluation Conditions

Surfactant: 0.1 – 10 mmol/dm³, Polymer: 8.3 ppm, Temperature: 25°C

- Adding PN-100 to surfactant solution can reduce the critical micelle concentration (CMC).

PN-100 can potentially reduce the amount of surfactant used; this is because various functions (cleaning, penetration, etc.) of the surfactant substantially change around the CMC. - Adding PN-100 to surfactant solution reduces the adsorption Gibbs energy (ΔG abs). This suggests that PN-100 promotes the adsorption of surfactants to hydrophobic surfaces.

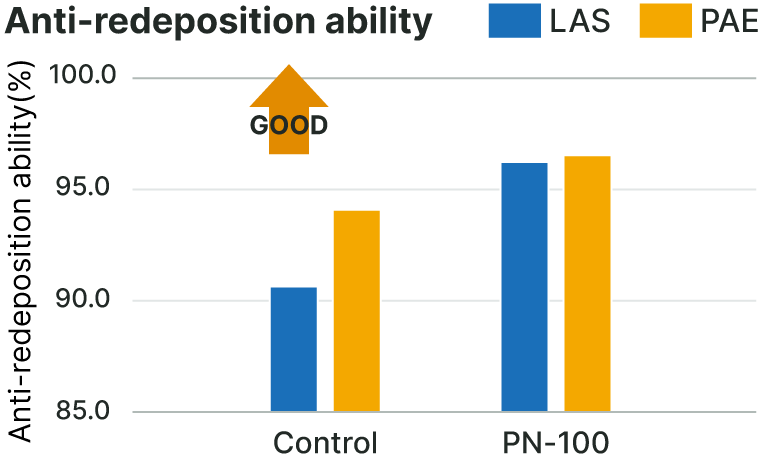

<Anti-redeposition Ability in Laundry Detergents>

The final application of PN-100 we will introduce here is its usage as a raw material in laundry detergents.

PN-100 can substantially improve the anti-redeposition ability in laundry detergents, by preventing the redeposition of dirt (phenomenon when dirt that is washed off during a wash cycle then reattaches to the clothing).

Evaluation Method

A cloth soiled with natural clay and a white cloth (control cloth for redeposition) are put into a bathtub and cleaned together.

After the cleaning is complete, a color difference meter is used to evaluate the degree of soiling of the white cloth.

The evaluation is done a total of three times.

The white cloth is used repeatedly.

Evaluation Conditions

Equipment: Targotometer, Surfactant: 250 ppm, Polymer: 8.3 ppm, Water hardness: 15 dH, Temperature: 25°C, Bath ratio: 30

*LAS: Linear alkylbenzene sulfonate

*PAE: Polyoxyethylene alkyl ether

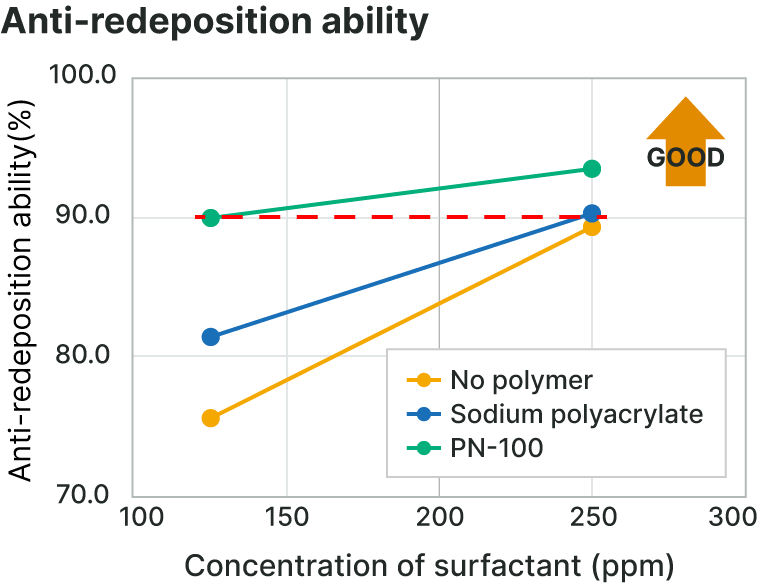

In terms of anti-redeposition ability as well, PN-100 can substantially reduce the amount of surfactant used in laundry detergents.

This experiment shows that adding PN-100 can halve the amount of surfactant used in laundry detergents with the same performance.

Evaluation Method

Natural clay and a white cloth (control cloth for redeposition) are put into a bathtub and cleaned together.

After the cleaning is complete, a color difference meter is used to evaluate the degree of soiling of the white cloth.

The evaluation is done a total of three times.

The white cloth is used repeatedly.

Evaluation Conditions

Equipment: Targotometer, Surfactant: 125 or 250 ppm (LAS:PAE = 1:1), Polymer: 8.3 ppm, Water hardness: 15 dH, Temperature: 25°C, Bath ratio: 30

*LAS: Linear alkylbenzene sulfonate

*PAE: Polyoxyethylene alkyl ether