Hybrid Monomers VEEA™, VEEM™ Hybrid monomers

- Main Applications

Ink, Coating, Photo resist, Adhesives, Stereo lithography

- Applications

- Functions

Basic Information

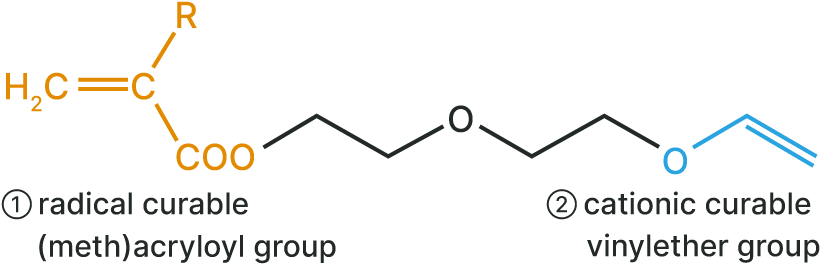

VEEA™: 2- (2-Vinyloxyethoxy)ethyl acrylate

VEEM™: 2- (2-Vinyloxyethoxy)ethyl methacrylate (under developing)

(1) Radical polymerizable (meth)acryloyl group

- Polymerization is not inhibited by water and bases

- Has many co-polymerizable monomers

- Has no dark reaction

(2) Cationic polymerizable vinyl ether group

- Polymerization is not inhibited by oxygen

- Good dilutability

- Good adhesion

| VEEA™ | VEEM™ | |

|---|---|---|

| CAS No. | 86273-46-3 | 76392-22-8 |

| Molecular Formula | C9H14O4 | C10H16O4 |

| Molecular Weight | 186.20 | 200.23 |

| Appearance | Colorless and transparent liquid | Colorless and transparent liquid |

| Boiling Point | 115 – 116°C/13.3 hPa | 122 – 123°C/13.3 hPa |

| Specific Gravity | 1.04g/mL(15℃) | 1.03 g/mL (15°C) |

| Viscosity | 3.65 mPa·s | 3.19 mPa·s |

| Solubility | H2O:18g/L(30℃) Organic solvent: Dissolve arbitrarily | H2O:2.2g/L(30℃) Organic solvent: Dissolve arbitrarily |

Features and Properties

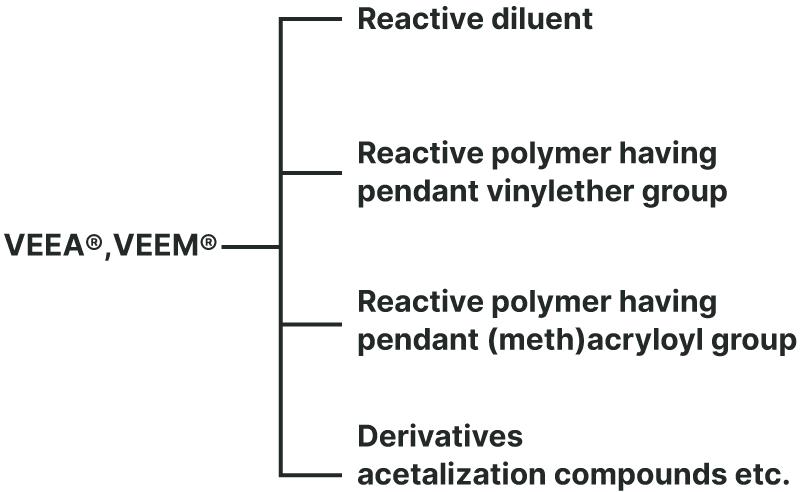

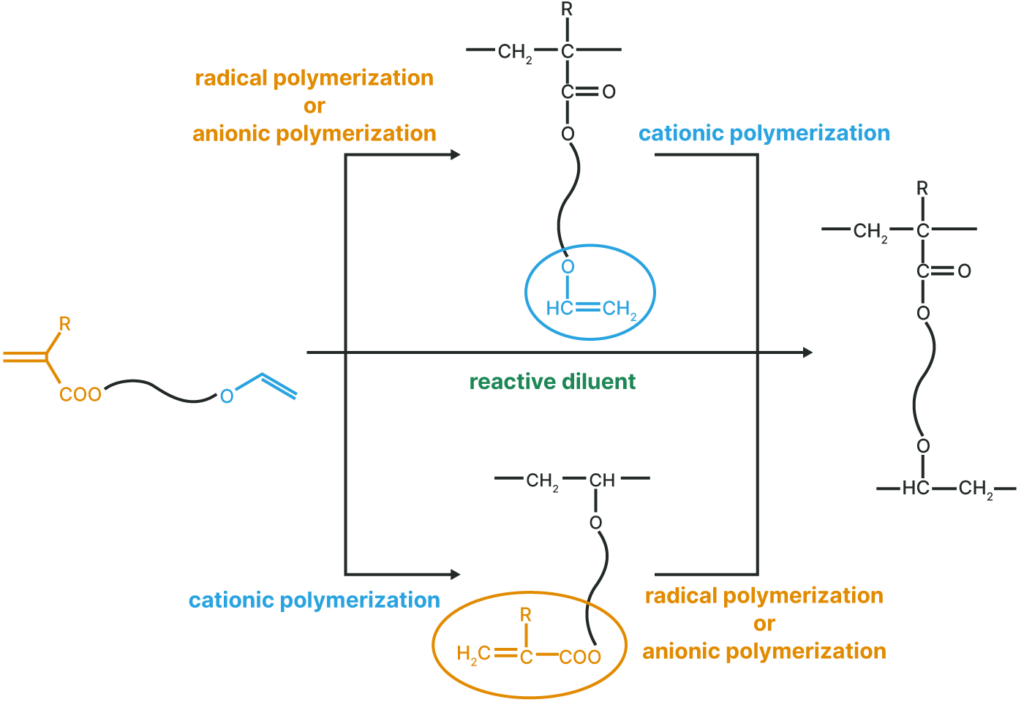

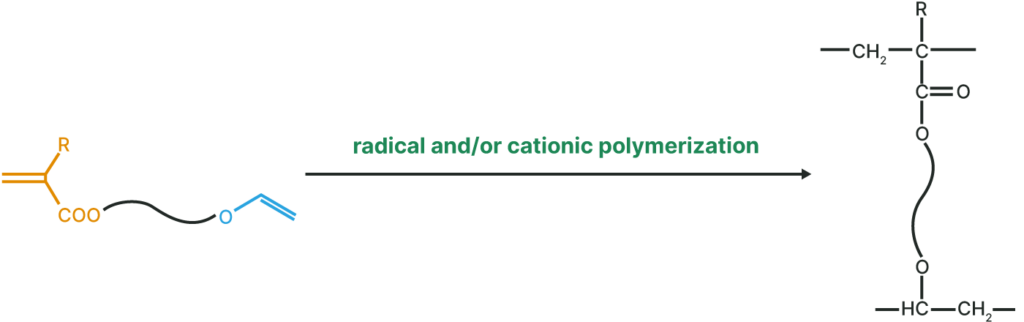

- VEEA™ and VEEM™ are monomers with unique structures having different types of polymerizable functional groups in one molecule: radical polymerizable (meth)acryloyl groups and cationic polymerizable vinyl ether groups.

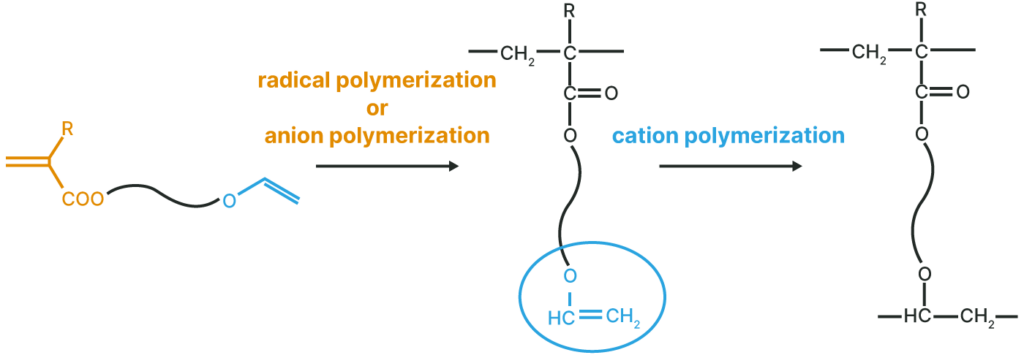

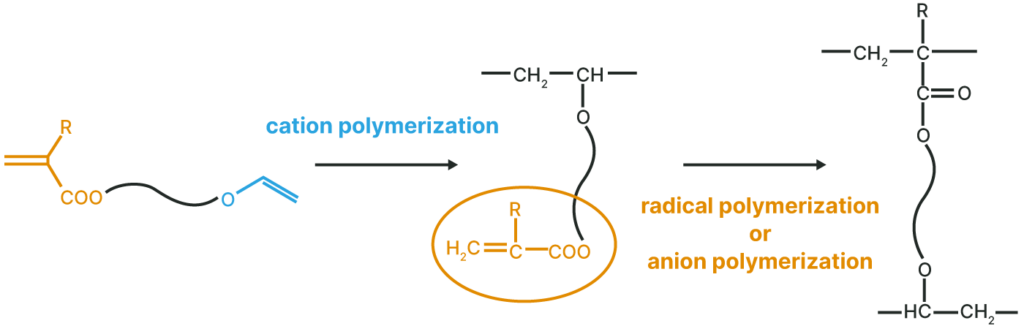

- By selecting the polymerization method, unique polymers with (meth)acryloyl or vinyl ether groups as pendant groups can be obtained.

- VEEA™ and VEEM™ have excellent UV curability as monomers.

Polymerization Method

Details of Functions

Reactive diluent

- VEEA™ and VEEM™ can be used as a reactive diluent for heat, UV and EB curable inks.

- VEEA™ and VEEM™ are less sensitive to curing inhibition by oxygen in the air, and even thin films (several microns)

UV Curing Properties of VEEA™

| Run No. | 1 | 2 | 3 | |

|---|---|---|---|---|

| VEEA™ | 100 | – | – | |

| DEGDA | – | 100 | 53.53 | |

| DEGDV | – | – | 46.47 | |

| Irgacure907 | 1 | 1 | 1 | |

| UV curing performance (1) | 0.1 J/cm2 | – | – | — |

| 0.2 J/cm2 | – | – | — | |

| 0.3 J/cm2 | ++ | + | — | |

| 0.4 J/cm2 | ++ | + | — | |

| 0.5 J/cm2 | ++ | + | — | |

| UV curing performance (2) | 1 pass | ++ | – | — |

| 2 pass | ++ | – | — | |

| 3 pass | ++ | – | — | |

| 4 pass | ++ | – | — | |

| 5 pass | ++ | – | — | |

UV curing performance (1): UV irradiation equipment: PM25C-100 (USHIO Inc.) 250 W ultra-high pressure mercury vapor lamp (main wavelength = 365 nm), thickness: 300 μm, surface tackiness: judged by finger touch (++ = tack-free, — = uncured) (++ = tack-free, — = not cured)

UV curing performance (2): UV irradiation device: UB031-5BM (EyEGRAPHICS), 80 W high pressure mercury vapor lamp, thickness: 30 μm, line speed: 14 m/min, distance from light source: 10 cm, irradiation energy per pass: 125 mJ/cm2, Irradiation energy per pass: 125 mJ/cm2, Surface tackiness: Tack-free to the touch (++ = tack-free, — = not cured)

UV curing properties of VEEA™ and VEEM™ as reactive diluents

| Run No. | 4 | 5 | 6 | 7 | 8 | 9 | |

|---|---|---|---|---|---|---|---|

| Unsaturated polyester resins | 60 | 60 | 60 | – | – | – | |

| Bis A type epoxy resin | – | – | – | 60 | 60 | 60 | |

| VEEA™ | 40 | – | – | 40 | – | – | |

| VEEM™ | – | 40 | – | – | 40 | – | |

| DEGDA | – | – | 40 | – | – | 40 | |

| Irgacure907 | 1 | 1 | 1 | 1 | 1 | 1 | |

| Viscosity (mPa・s @ 25℃) | 1102 | 1038 | 2670 | 295 | 289 | 855 | |

| UV curing performance | 1 pass | + | – | – | – | – | – |

| 2 pass | + | – | – | ++ | – | ++ | |

| 3 pass | ++ | – | – | ++ | – | ++ | |

| 4 pass | ++ | + | + | ++ | + | ++ | |

| 5 pass | ++ | ++ | + | ++ | ++ | ++ | |

| 7 pass | ++ | ++ | + | ++ | ++ | ++ | |

| Pencil Hardness (JIS K-5400) | F | HB | B | F | F | F | |

| Acetone rubbing (100times) | ++ | ++ | ++ | ++ | ++ | ++ | |

UV curing performance: UV irradiation device: UB031-5BM (EYEGRAPHICS Co., Ltd.) with 80 W high-pressure mercury lamp;

Thickness: 30 μm, Line speed: 14 m/min, Distance from light source: 10 cm, Irradiation energy per pass: 125 mJ/cm2, Surface tackiness: determined by finger touch (++ = tack free, — = uncured) Pencil hardness: measured after 10 passes curing. Acetone rubbing: measured after 10 passes curing

Polymer with a pendant Vinyl Ether Group

Thermal, UV, and EB curable polymers are obtained by radical or anionic polymerization.

Polymer with a pendant (Meth)Acryloyl Group

Thermal, UV, and EB curable polymers are obtained by cation polymerization.

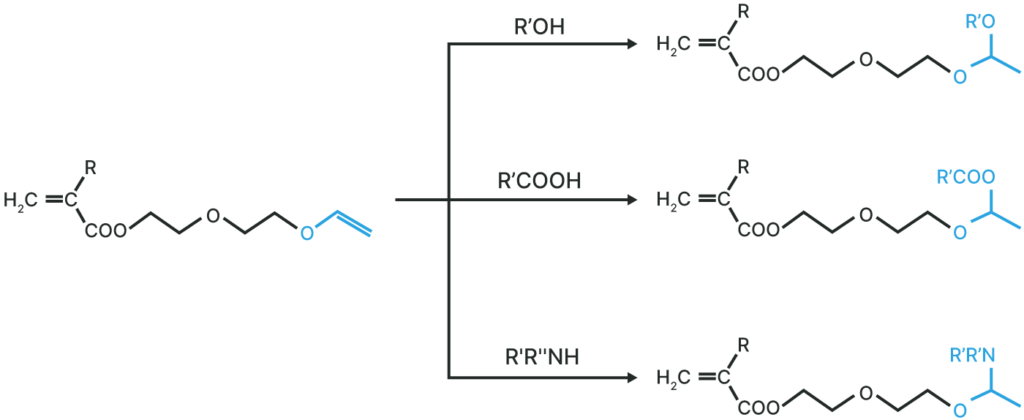

Derivatives

Various acetals can be synthesized by addition reaction to vinyl ether groups.

Examples of Applications

- Coatings: Wood coatings, Film coatings, Hard coatings, Optical disk coatings, Optical fiber coatings, etc.

- Ink: Inkjet inks, Screen inks, Offset inks, Gravure inks, etc.

- Photo Resists: Dry film resist, Semiconductor resist, Photosensitive resin plate, etc.

- Adhesives

- Stereo-lithography

etc.

Utilities