Typical Applications

Nippon Shokubai’s fine particles have various properties, which make them suitable for use in a variety of applications including those listed below.

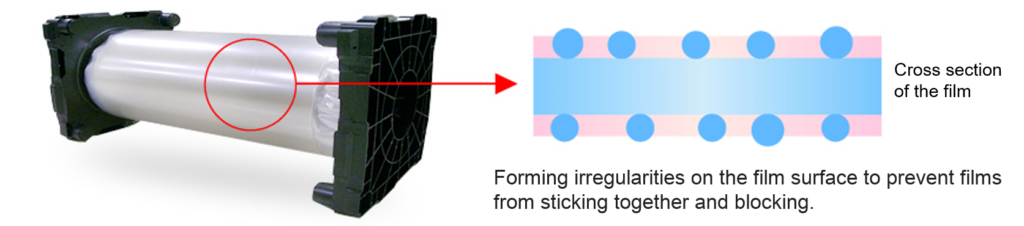

Anti-blocking Agents/Slipping Agents

Nippon Shokubai’s fine particles are used in a variety of plastic materials as anti-blocking agents and slipping agents of plastic films.

The EPOSTAR™ MV Series is generally used by kneading the particles into plastic materials.

The high heat resistance of these particles enable the prevention of coloring caused by heating during kneading.

The particle diameter can also be adjusted in accordance with the thickness of the film, and as there is little scratching of films compared to inorganic silica particles, there is no impairment of the film’s transparency.

It is also possible to modify the fine particles’ surfaces to enhance their affinity with film resins.

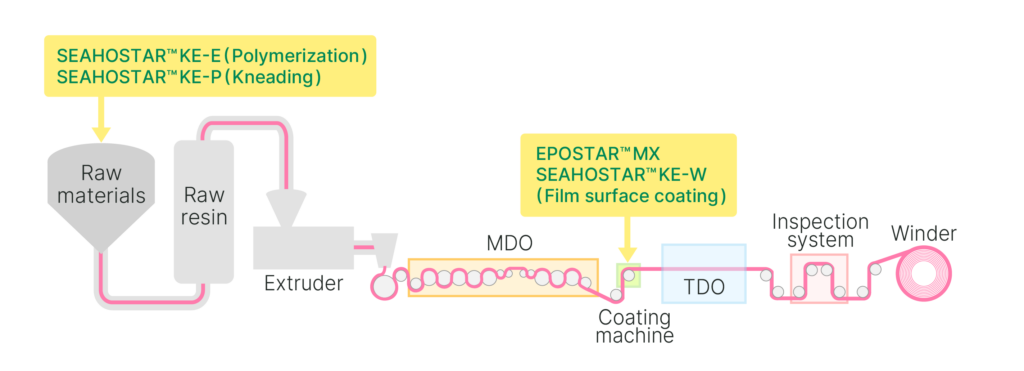

Similar to the abovementioned EPOSTAR™ MV Series, the SEAHOSTAR™ KE-P Series is also used by kneading the particles into plastic materials.

Meanwhile, the ethylene glycol dispersion KE-E Series can be used in the processes to manufacture PET resins, making it easier to manufacture PET resins with good dispersibility.

The EPOSTAR™ MX Series and SEAHOSTAR™ KE-W Series also use their water dispersion features to achieve properties such as slip coatings on film surfaces; these particles can be used in combination with various film properties.

Please inquire about adjusting the particle diameter and refractive index and improving solvent resistance and heat resistance in accordance with your needs and preferences.

Examples of Use of Fine Particles in the Film Manufacturing Process

Light Diffusion Agents

With a wide range of refractive indices, from the low refractive index of the SEAHOSTAR™ Series (inorganic silica particles (n = 1.43)) to the high refractive index of the EPOSTAR™ Series (benzoguanamine-formaldehyde resin particles (n = 1.66)), and a lineup of average particle diameter from submicrons to 10 microns, these products are used in the optical films of liquid crystal panels and as diffusion agents in LED lighting.

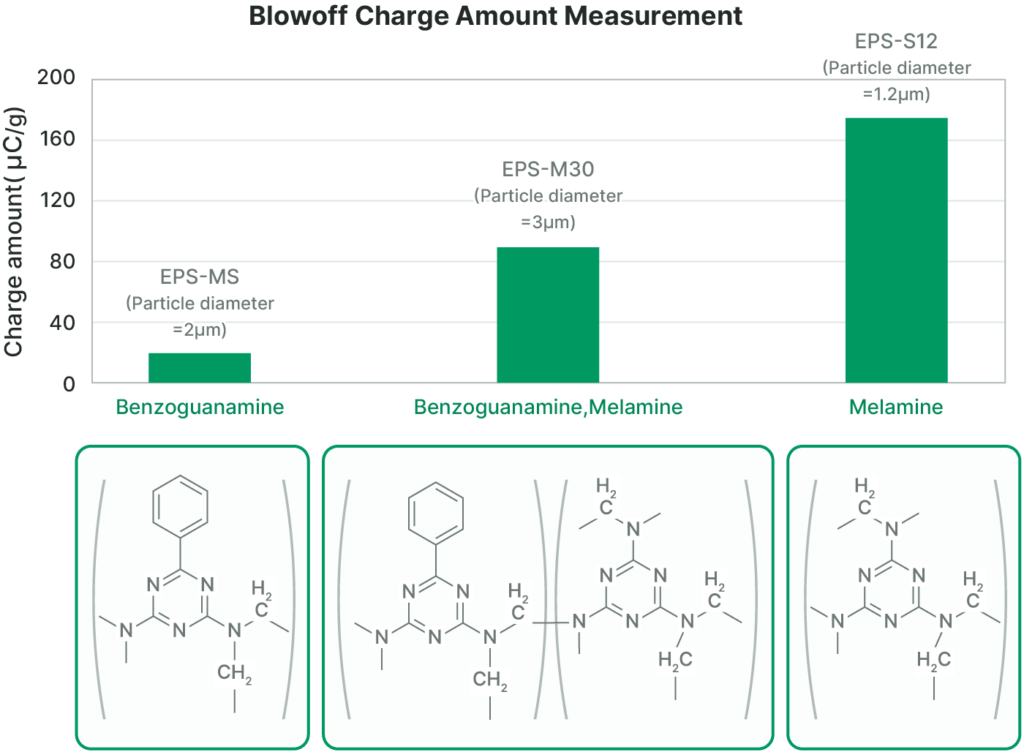

Toner Additives

The EPOSTAR™ Series of products have compounds that contain many nitrogen atoms, such as melamine and benzoguanamine, in the resin skeleton, which gives them a high positive charge as particles.

Particles with a positive charge are generally particles that have been treated with amino-based surface treatment agents. Compared to these particles, EPOSTAR™ particles have a noticeably high positive charge with virtually no variation in the electric charge amount of each particle, enabling them to show stable electrostatic properties and be ideal for use as charge control agents for toners.

Positive Charge Data of EPOSTAR™

Role of Toner Additives

Toners are composed of binder resins, coloring materials, charge adjusting agents, waxes, and external additives.

External additives play an important role in adhering to the surface of the toner and controlling properties such as electrostatic and anti-blocking properties, as well as fluidity.

Nippon Shokubai’s EPOSTAR™ Series of products contain many nitrogen atoms that enable the use of positive charges and make them ideal for use as agents for controlling and maintaining electrostatic charge.

Resin fillers

SEAHOSTAR™ products are used as fillers of various resins in order to modify resins.

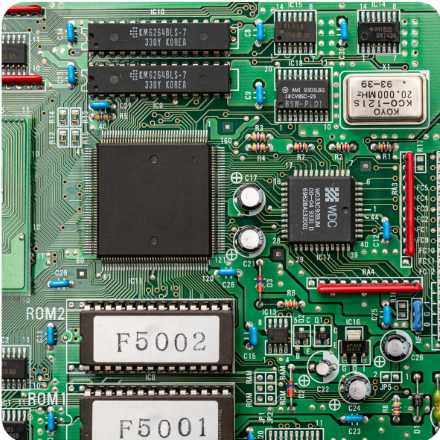

SEAHOSTAR™ products are particularly ideal for use as resin fillers for electronic materials, applying their features of having minimal coarse particles and impurities.

SEAHOSTAR™ KE-S Series

SEAHOSTAR™ Surface Treatment Type

SEAHOSTAR™ Properties

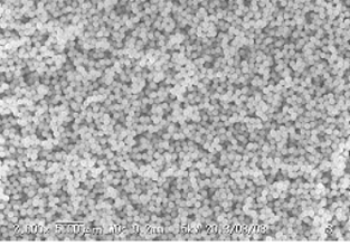

- Perfectly spherical with a sharp particle size distribution and minimal coarse particles

- Manufactured in dedicated equipment and free from contamination of foreign components

- Able to make the particles surfaces hydrophobic by modifying the surfaces

- Does not contain radioactive substances

-1.png)

Able to make the particles’ surfaces hydrophobic

SEAHOSTAR™ Properties for Sealing Resins

- As shown in the above (left) diagram, silica fillers have a broad particle size distribution and contain coarse substances (single particles), which causes clogging and scratching on IC chips.

- The SEAHOSTAR™ Series of products have a sharp particle size distribution, with minimal coarse substances (single particles, secondary particle aggregates), making them ideal for use in sealing resins, irrespective of the mounting method used (CUF, NCP, NCF, etc.).