Fine Particles Design Technology

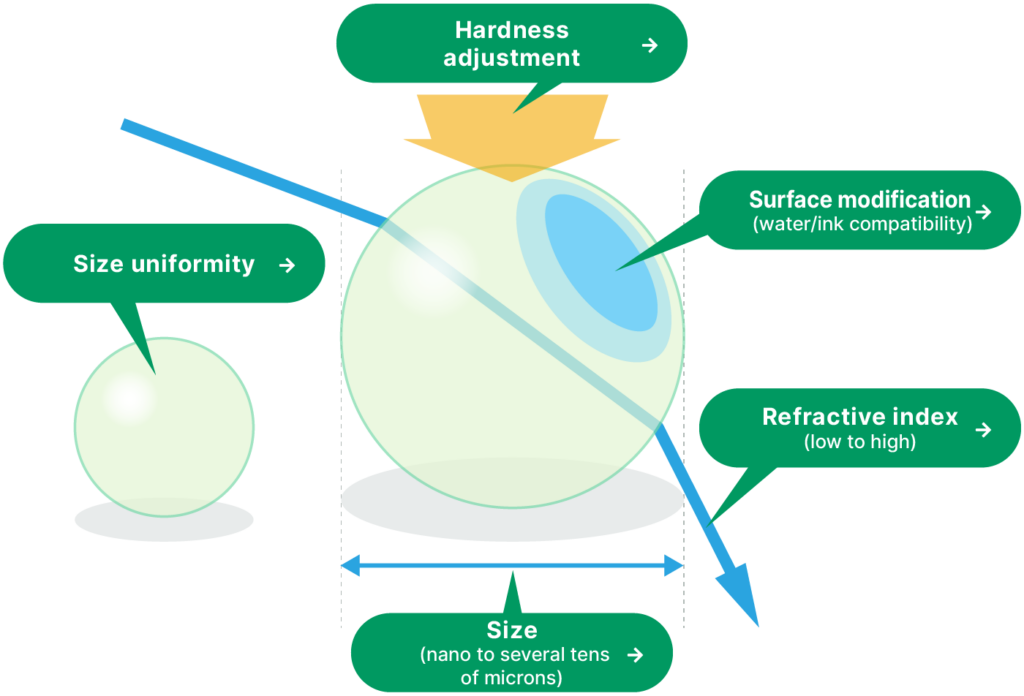

Nippon Shokubai uses materials of inorganic particles, organic-inorganic hybrid particles, and organic particles, and also applies various technologies to meet our customers’ every need, such as controlling surface polarity and positive and negative charges, as well as controlling basic physical properties such as particle diameter, particle size distribution, refractive index, and hardness, and achieving UV resistance and heat resistance.

Please check the fields that you are interested in.

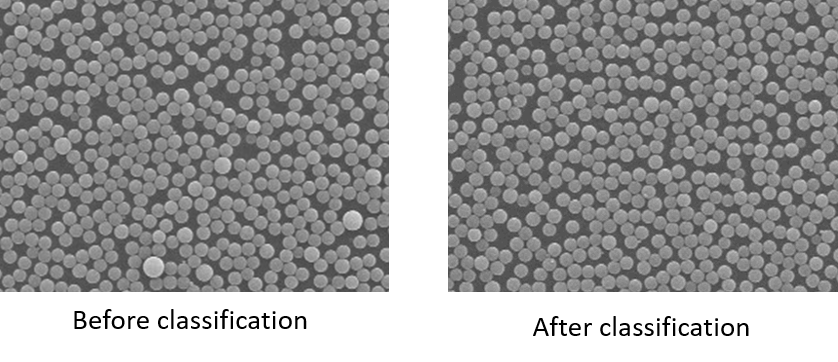

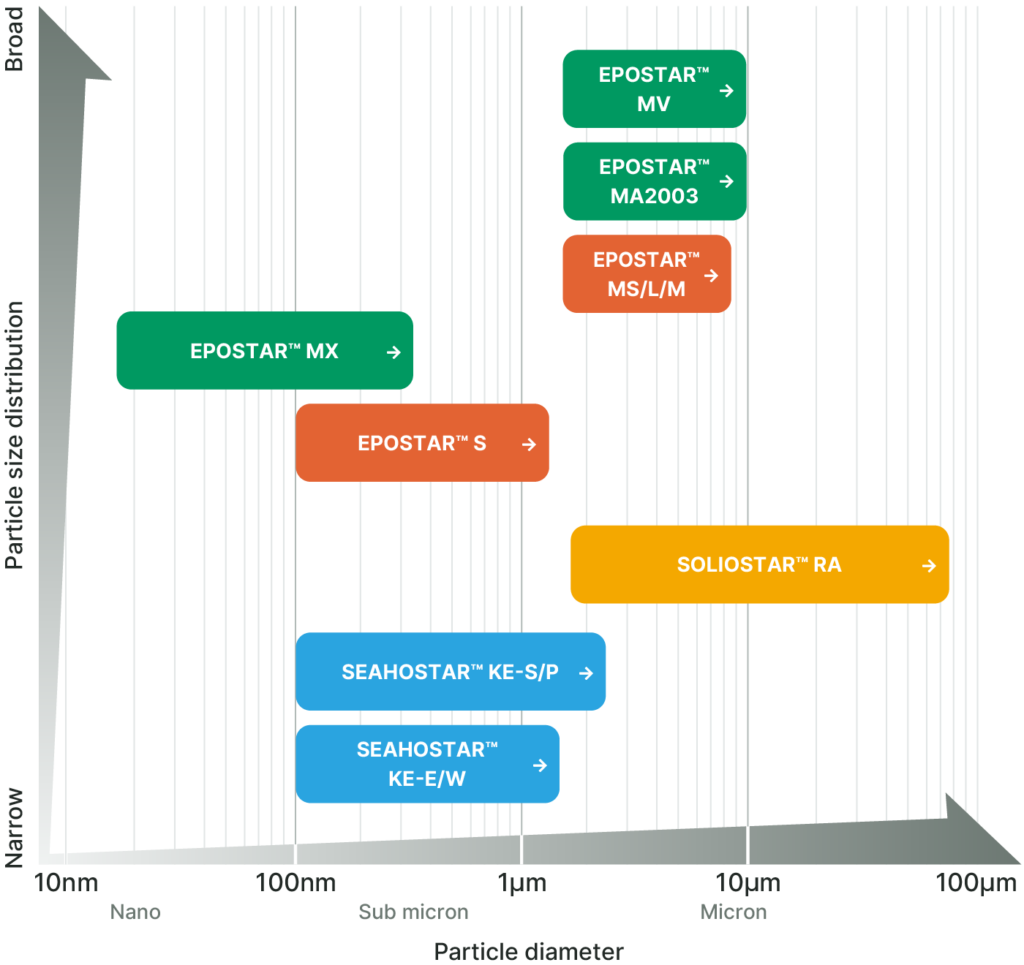

Particle Diameter and Particle Size Distribution Adjustment

Using a variety of methods including suspension polymerization, seed polymerization, emulsion polymerization and precipitation polymerization, we are able to offer a lineup of fine particles with widely controlled properties such as particle diameter from nano to micron sizes and particle size distribution from polydispersion to monodispersion.

By applying pulverization and classification methods to each type of particles and removing aggregates and coarse particles, they can also be used in applications that require high quality.

Example of Controlling Particle Size Distribution

-1.png)

Example of Controlling Coarse Particles Quantity

Particle Diameter and Particle Size Distribution

Refractive Index Adjustment

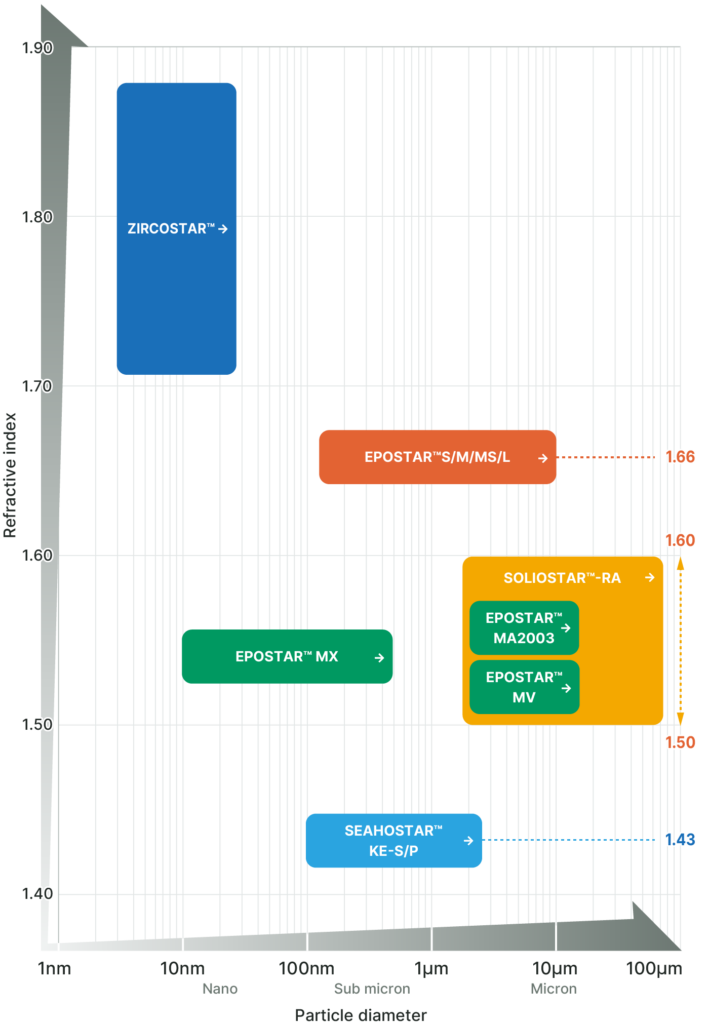

Nippon Shokubai offers a lineup of zirconia, silica, acrylic, acrylic-styrene, melamine, and other products, which enables us to widely correspond to refractive indexes from 1.4 to 1.9.

The EPOSTAR™ S, M, L, MS Series of melamine and benzoguanamine fine particles are particularly popular for use in applications that require high diffusion.

The acrylic-based EPOSTAR™ MV Series, acrylic-styrene-based EPOSTAR™ MA2003, and the organic-inorganic hybrid SOLIOSTAR™ RA Series have refractive indexes that can be adjusted in the 1.50 – 1.60 range in 0.01 increments.

Additionally, when mixed with technology to control hardness, it is possible to achieve both haze adjustment and anti-blocking properties that are required in film additive applications.

Example of Adjusting the Refractive Index

.png)

Particle Diameter and Refractive Index

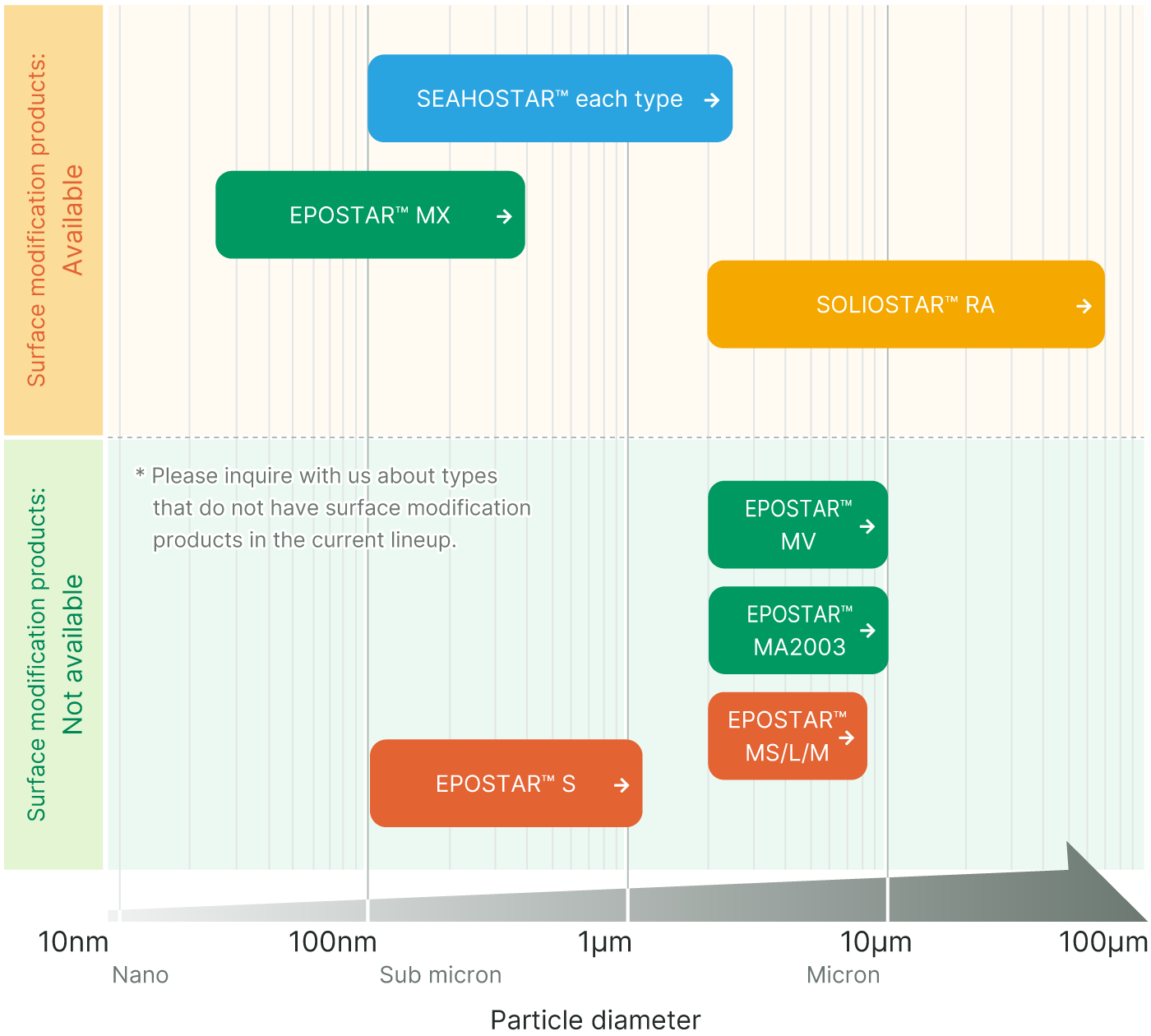

Surface Modification Technology

Nippon Shokubai is able to meet a wide range of surface modification needs using a variety of treatment processes such as drying, wetting, and surface state adjustment at the particle synthesis stage.

Particularly for the silica particles SEAHOSTAR™ KE Series, we offer a variety of surface treatment types that are popular for use as resin fillers and in other applications.

We are able to customize our products to meet the needs and preferences of our customers. Please inquire with us about introducing functions and degrees as required.

Example of Surface Modification

.png)

Example of Surface Polarity Control

.png)

Particle Diameter and Surface Modification

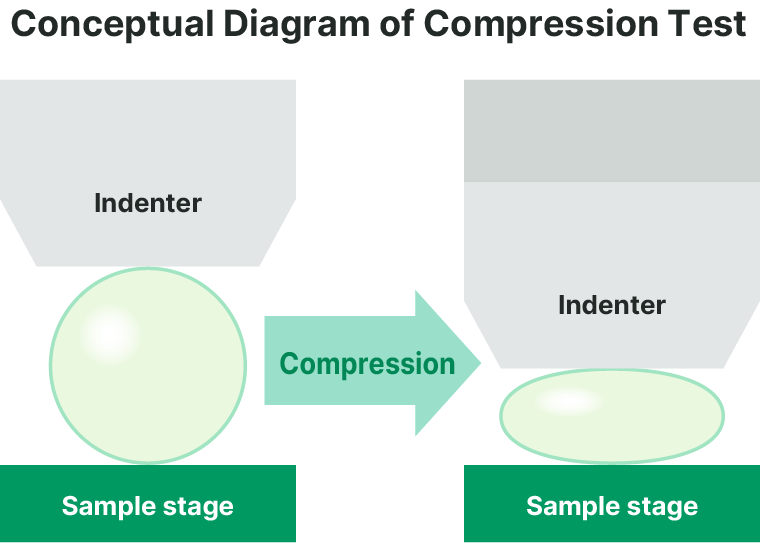

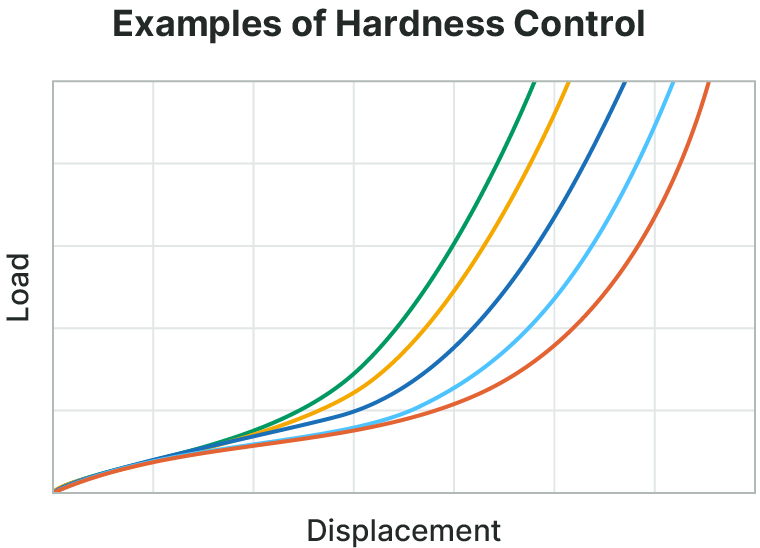

Hardness Adjustment

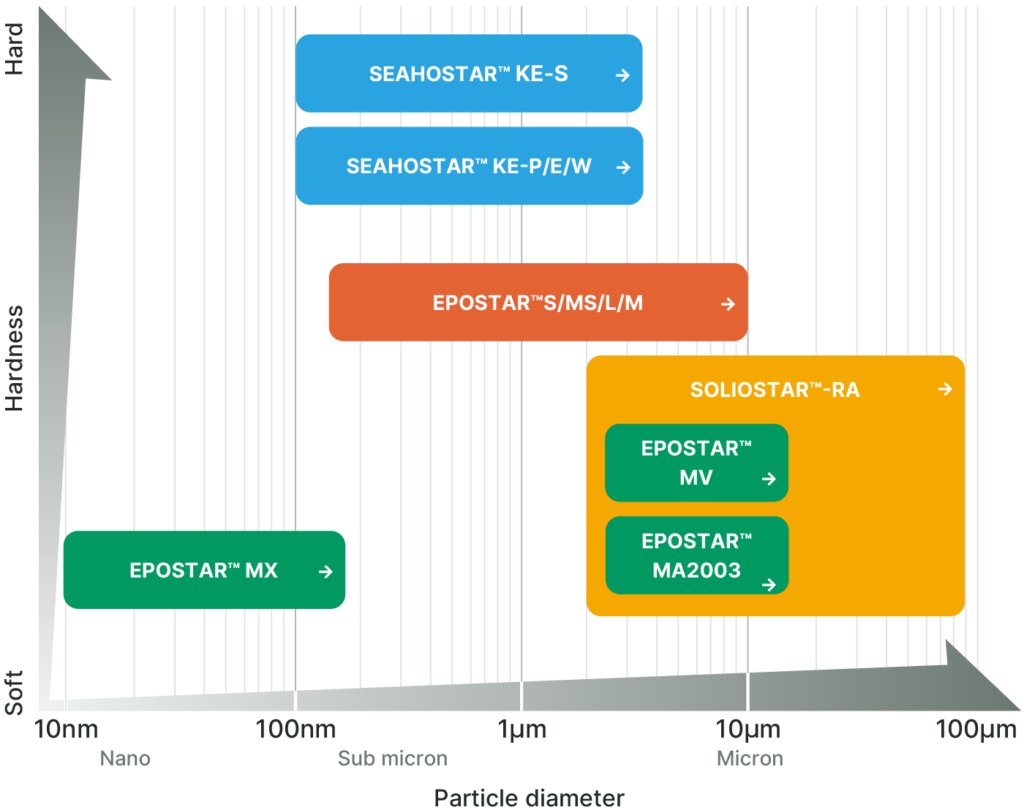

Nippon Shokubai offers a lineup of products that cover a wide range of hardness, from hard to soft, depending on various materials such as silica, acrylic, acrylic-styrene, and melamine.

Particularly, the organic-inorganic hybrid SOLIOSTAR™ RA Series has an extremely wide hardness control range. Using the organic-inorganic hybrid properties, it is possible to control a degree of hardness that is between silica and organic particles.

Particle Diameter and Hardness