Chemical Safety

Basic Approach

As per RC Basic Plan, which was formulated in light of both domestic and international situations regarding chemical management, the Nippon Shokubai Group has been enhancing chemical management through keeping legal compliance and providing information to stakeholders, in order to maintain Zero legal and/or social problems related to chemical safety throughout the entire life cycle of our products.

Promotion System

Targets and Results

| FY2024 targets | FY2024 results | FY2025 targets |

|---|---|---|

| Completely avoid (legal/social) problems with chemical products | Cases involving problems with chemical products: 0 | Legal and/or social problems related to chemical safety*: 0 |

regulations related to chemicals have had a social impact, such as receiving guidance from relevant government

agencies or being reported in the mass media.

Initiatives

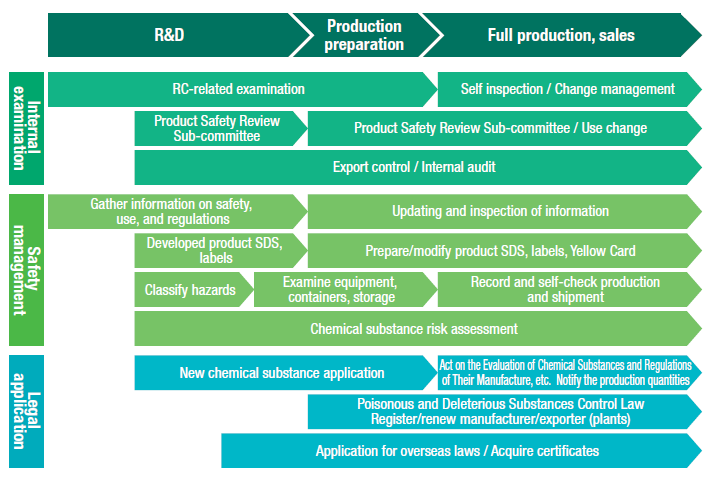

Rigorous chemical product control throughout product lifecycles

We have been conducting thorough chemical management for each stage of product lifecycles from research and development to disposal after usage by establishing operation scheme, rules, systems, etc. to comply with domestic and foreign laws and regulations and providing appropriate information on chemical safety to customers.

Chemical Management System

Efforts toward product safety

We strive to ensure the safety of new products and swiftly put them on the market by appropriately and promptly examining the safety and compliance status throughout the chemical product lifecycles at each stage, from research and development to commercialization.

Product safety initiatives

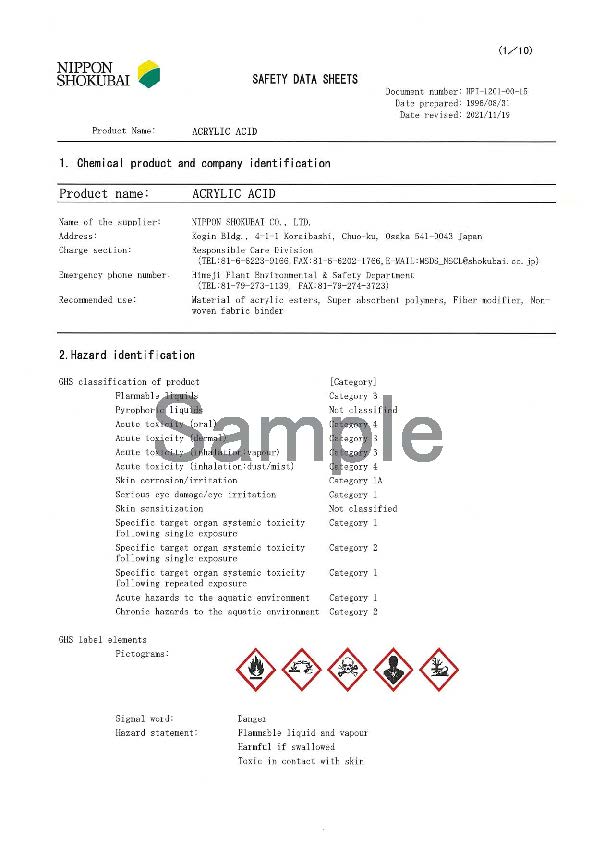

We create GHS*1-compatible SDS*2, warning labels, and Yellow Cards*3 to promote the dissemination of information to our customers and the education of our employees. We also conduct strict checks of products intended for different end-uses (e.g. active pharmaceutical ingredients, pesticides, cosmetics, food additives) that include action by the Product Safety Review Subcommittee to comply with the Product Liability Act (PL Act).

*1 GHS: An abbreviation for Globally Harmonized System of Classification and Labeling of Chemicals, GHS reflects the physical, health and environmental hazards of chemicals determined in accordance with international standards. Under this system, chemical products identified as presenting a hazard are categorized according to international standards and displayed on containers and in the respective SDS. Countries around the world have also introduced this system on the recommendation of the United Nations. This system is enforced in Japan through the Industrial Safety and Health Act.

*2 SDS (Safety Data Sheet): The Safety Data Sheet lists a chemical’s properties as well as data on its hazards, applicable laws, proper handling and transportation requirements, and specific emergency response measures in a prescribed format. We prepare an SDS for each of the products we manufacture and develop and provide them to our customers. We are implementing a system for distributing these documents to all employees through our chemical substance management system.

*3 Yellow Card: The yellow card is a unique initiative in Japan, which lists a product’s hazards, first aid procedures in an accident, and emergency contact information. As part of its promotion of RC, the Japan Chemical Industry Association (JCIA) prepares and manages guidelines on the procedures for preparing a yellow card in order to strengthen first aid measures in the event of an accident. Carriers transporting dangerous goods are encouraged to carry a yellow card to report information about the cargo to the fire brigade in the event of an accident.

Operating our chemical substance control system

We established a chemical substance control system to centrally manage information on chemical substances, raw materials, product-related hazards, laws and regulations, and more, and use the system for many purposes, including evaluating risks, preparing SDS, and responding to customers’ inquiries about the chemical substances in products. We are also sustaining efforts to update information and improve the functionality of the system, and in FY2020 launched an automatic warning label-creating function based on the system, that we began using for products in development.

Accommodating chemical registration requirements within and outside Japan

We work with specialized agencies and Group companies outside Japan to comply with laws and regulations, such as the Chemical Substances Control Act and the Industrial Safety and Health Act of Japan, TSCA in the USA, and REACH in the EU.

We also hold training on laws and regulations and briefings on new systems pertaining to chemical product control on a regular basis to inform our employees and foster in them a sense of respect for the laws and regulations.

Additionally, regarding acrylic acid—a priority assessment chemical substance under the Chemical Substances Control Act—an organization to which we belong conducts safety tests for aquatic life, and we submit information and otherwise respond proactively to risk assessments by the central government.

Import and export control initiatives

To ensure faithful compliance with import and export regulations, we establish and maintain Company rules, inform everyone in the Company of decisions as to controlled items, establish and maintain a shipping management system tied to our central accounting system, and conduct internal training on a regular basis. Additionally, our annual internal audit revealed no problems with exports during CY2024. Furthermore, we have proceeded to enhance our export control system by implementing a new export trade management system in November 2024.

Promoting a voluntary initiative of the JCIA

We participate in GPS/JIPS, a voluntary initiative for strengthening chemical management promoted by the Japan Chemical Industry Association (JCIA), which prepares and releases a safety summary to the public.