RC Initiatives

Nippon Shokubai proactively implements RC initiatives based on environmental protection, process safety and disaster prevention, occupational safety and health, chemical safety, quality, and communication with society.

RC Policy

This Policy has been approved by the Sustainability Promotion Committee (formerly the TechnoAmenity Promotion Committee; which is chaired by the President and composed of Inside Directors of the Board, Executive Officers and others appointed by the President).

In order to achieve our Group Mission and put our Values, Code of Conduct, and Safety Philosophy into practice, the Nippon Shokubai Group takes the priority actions listed below with regard to the environment, safety, and quality. In doing so, we consider contributing to society by providing technologies and products that facilitate environmental protection to be a key management strategy; our actions are guided by the principle of Sustainable Development, and we work conscientiously to achieve harmony with environmental conservation on a global scale.

- We consider environmental impact and take steps toward environmental protection throughout the entire lifecycle of our products, from development to disposal.

- We strive to ensure safety for our employees and society at large by striving to completely avoid accidents and injuries based on our Safety Philosophy of “Safety takes priority over production.”

- We consider the health of our employees, logistics partners, customers, and others by verifying the safety of the raw materials, intermediate goods, products, and other chemical substances we work with.

- We consistently provide reliable, high-quality products and services that satisfy our customers.

- We publish the outcomes of the aforementioned activities in an effort to ensure that our message is understood properly.

RC Promotion System

Our RC Promotion Committee chaired by the Company President reviews basic and overall matters to make concrete progress in implementing the RC Policy and guidelines set out in other company regulations in all activities: environmental protection, process safety and disaster prevention, occupational safety and health, chemical safety, quality, and communication with society. We have also established specialized subcommittees under the RC Promotion Committee to promote company-wide RC initiatives.

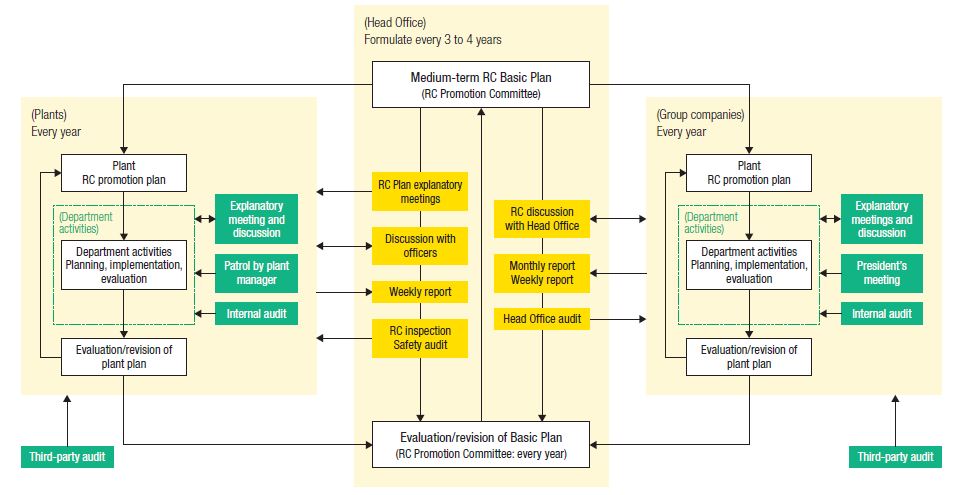

Promotion Cycle for RC Initiatives

To put the RC Policy into practice, the Group makes efforts to contribute to society and fulfill its corporate social responsibility by undergoing the PDCA cycle each year within the promotion cycle for RC initiatives in collaboration with each plant and Group company.

Flow of RC Initiatives

Flow of promotion cycles

[Head Office]

Every three to four years, the RC Promotion Committee chaired by the Company President formulates a Medium-term RC Basic Plan to coincide with the duration of the company’s Medium-term management plan. Additionally, each year the council selects the focuses of inspections, conducts RC inspections and safety audits to check and evaluate the status of activity implementation at our plants, and revises plans as necessary.

[Plants]

Each year, the RC Committee at each plant chaired by the plant manager formulates a Plant RC promotion plan based on the Company-wide Medium-term RC Basic Plan and evaluations of the previous year’s activities. Each department formulates their department activity plan that outlines specific activities to be implemented in consideration of important issue that department faces.

The progress of these activities is checked not only through plant manager patrols, discussions at departments, and internal audits of ISO and other management systems, but also through discussions and RC inspections conducted by Head Office officers as well as third-party audits. In light of the results, department activity plans are revised as necessary to undergo the PDCA cycle in pursuit of continuous improvement.

[Group companies]

Like Nippon Shokubai, Group companies formulate plans based on the Medium-term RC Basic Plan each year; however, their respective RC promotion plan are formulated in consideration of their business activities and the laws and regulations in their country.

They show the progress of their activities with the Head Office through weekly and other regularly scheduled reports and online meetings, and the Head Office also conducts regularly scheduled discussions and audits to check on the progress. In light of the results, the activities are revised as necessary to undergo the PDCA cycle in pursuit of continuous improvement.

The Head Office also encourages Group companies to interact with each other in an effort to enhance each other’s activities.

RC Inspections

We organized an RC Inspection Committee led by Company officers and chaired by the Director of the Board in charge of Production & Technology to conduct annual RC inspections for continual improvement of RC initiatives at the Himeji and Kawasaki Plants.

We strive to continuously improve RC initiatives by sending reports containing concerns, suggestions for improvement, and other information to the plants.

What are RC inspections?

Our RC inspections date back 49 years to February 1974, soon after we established our Safety Philosophy of “Safety takes priority over production” in 1973.

We referred to them as “safety inspections” until 2003, and have continued conducting them in an effort to put our Safety Philosophy into practice. Now, we conduct them based on the key topics set out each fiscal year and the implementation status of RC initiatives at each plant. The following are the key topics for RC inspections over the past several years.

| Medium-term Plan* | Fiscal year | Priority theme |

|---|---|---|

| 10th FY2017 to FY2020 | FY2017 (45th) | Initiatives for environmental protection |

| FY2018 (46th) | Prevention of quality issues and ensuring quality governance | |

| FY2019 (47th) | Prevention of recurrence of similar occupational injuries | |

| FY2020 (48th) | Prevention of process safety accidents | |

| FY2021 | FY2021 (49th) | Chemical substance management |

| 11th FY2022 to FY2024 | FY2022 (50th) | Initiatives for safety culture development and revisions toward more effective safety activities |

| FY2023 (51st) | Environmental Impact Reduction Activities |

FY2023 RC inspections

We conducted the RC inspection for FY2023 in person for the first time since FY2019, on October 31 for the Kawasaki Plant, and November 2 for the Himeji Plant, to check the implementation status of RC initiatives. The key topic was “Environmental Impact Reduction Activities”.

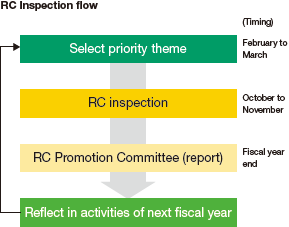

RC inspection procedure

RC inspections are conducted by the RC Inspection Committee from October to November each year after the key topic or topics for the year are selected from February to March of the previous fiscal year based on information such as problems outside the company and the results of internal RC initiatives.

The results are reported to the plants as well as the RC Promotion Committee chaired by the Company President, and are reflected in the activities of the following fiscal year.

The diagram below shows the procedure of RC inspections.

RC Training

We have continuously trained employees about RC initiatives to improve their overall understanding and mastery.

In FY2023, we provided trainings for new hires and for employees who promoted to assistant manager and manager based on RC training curriculum.