Group Companies in Japan

NIPPON POLYMER INDUSTRIES CO., LTD.

| Principal business | Manufacture and sale of acrylic resins |

|---|

Since FY2023, we have been implementing the “Reformers Initiative,” a company-wide effort to gather various opinions and suggestions for improvement from all employees and drive transformation based on that feedback. In FY2024, we held an annual presentation event in February called “Reformers Day” to summarize the year’s activities.

As a new environmental protection initiative, in FY2024, we held workshops under the guidance of external consultants to reduce steam usage in production equipment. First, we held study sessions to learn the basic knowledge and calculation methods necessary for considering steam usage reduction. In the subsequent workshops, we analyzed the possibility of reducing steam usage by comparing theoretical values and actual values of steam loss in reactors.

In the area of process safety and disaster prevention, we conducted our annual joint emergency drill with the municipal fire department. Additionally, as part of our ongoing efforts since FY2023 to update aging equipment, we carried out the second phase of the fire hydrant piping renewal construction.

We will continue to promote RC initiatives with the participation of all employees to the greatest extent possible, aiming for zero accidents and zero injuries.

Interview

Enhancement of wastewater treatment facility capacity and reduction of steam usage

At our company, the production of water-based acrylic resin accounts for approximately 90% of our total output, and wastewater generated from the cleaning of production equipment, tank trucks, and product containers averages about 150 tons per day. This wastewater is treated through chemical and biological processes.

This time, we improved our treatment capacity by renewing and expanding storage tanks, reviewing the use of auxiliary agents, and changing the aeration method. As a result, we achieved approximately a 20% increase in treatment capacity compared to previous levels, while still complying with emission standards such as COD levels.

Additionally, we are also working to reduce steam usage in the wastewater treatment yard. By reviewing operating conditions based on the improved treatment capacity, we found that steam usage could be significantly reduced. We are currently analyzing in details the effectiveness of this reduction.

We will continue our efforts to enhance treatment capacity and reduce steam usage.

Production Dept.

Production Control Section

NIPPON POLYMER INDUSTRIES

CO., LTD.

NIPPON NYUKAZAI CO., LTD.

| Principal business | Manufacture and sale of surfactant and other chemicals |

|---|

As part of our FY2024 activities in occupational safety and health, we participated both internal and external hands-on risk learning programs to further enhance sensitivity to hazards. We also shared the results of trend analysis of past occupational injury cases to raise safety awareness.

In terms of process safety and disaster prevention, we installed three security and disaster prevention cameras on the rooftop of the R&D Center at the Kawasaki Plant. These cameras can zoom up to 21 times, allowing for clear on-site confirmation in case of an emergency. This enables prompt decision-making and is expected to strengthen our emergency response system. Additionally, as part of our social contribution efforts, we have registered the administrative and welfare building at the Kawasaki Plant as a tsunami evacuation facility with Kawasaki City, making it available as a temporary evacuation site in emergencies.

In communication with society, the Kashima Plant held a discussion meeting on women’s empowerment with neighboring companies and conducted practical training through a dual education system with a local high school to strengthen ties with the local community. This training is conducted in parallel with classroom learning, allowing students to gain practical knowledge and experience while studying.

We will continue to promote RC initiatives in an effort to ensure safe operations.

CHUGOKUKAKO CO., LTD.

| Principal business | Manufacture and sale of adhesive-processed products and fine sphere particles |

|---|

In terms of occupational safety and health, we achieved zero injuries with and without lost workdays in FY2024. As part of our RC activities, in addition to continuing thorough near miss analysis and task risk assessments, we expanded the practice of pointing and calling—which had previously been limited to certain road crossings—to be implemented within each department.

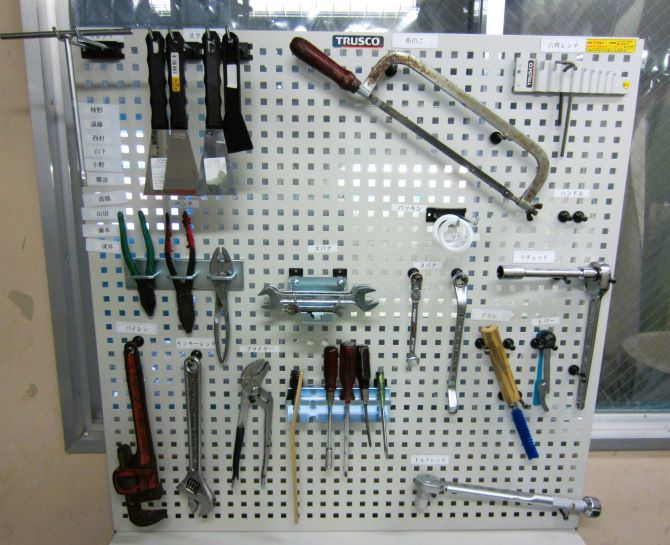

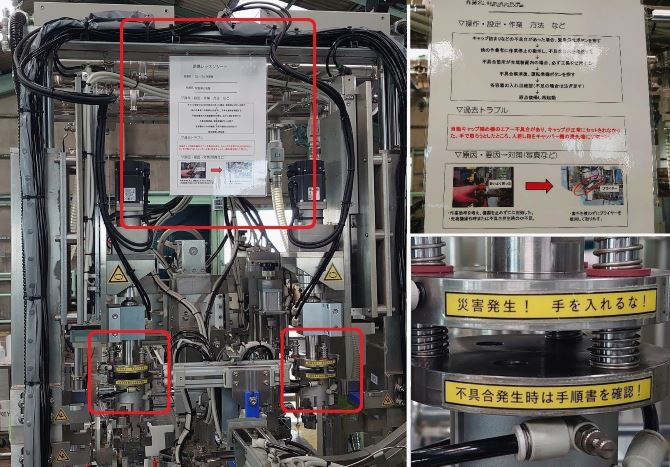

To further develop a culture of continuous improvement, we conducted the “Workplace Comfort Improvement Activity” in FY2024 as part of our ongoing workplace improvement activities that began in FY2020. In this initiative, we utilized external consultants to review 5S activities, methods for identifying “Waste, Unevenness, and Overburden,” and the steps for problem-solving. By practicing sort and set with a focus on work efficiency through 5S activities, our workplace has taken a stop closer to becoming a more comfortable work environment.

As part of our environmental protection efforts, we reduced waste by converting plastic pallets, which were previously treated as industrial waste and recycled externally into valuable resources.

We will continue to promote RC initiatives with the aim to completely avoid accidents and injuries reduce environmental impact.

Nisshoku Butsuryu Co., Ltd.

| Principal business | Logistics of chemicals |

|---|

The Nisshoku Butsuryu Group positions “providing environment-friendly, safe, and high-quality logistics services for chemicals and contributing to society through its RC initiatives” as its key management policy. Under this policy, we have been working on the reduction of GHG emissions as an initiative to reduce environmental impacts and promoting risk prediction as an initiative to achieve zero accidents and injuries. We also promote proper operation of advanced operation information systems and the introduction of vehicles equipped with Advanced Emergency Braking System as priority tasks.

We also worked on the following priority issues: prevention of environmental disasters and accidents, promotion of energy consumption reduction and resource conservation, prevention of accidents with vehicle equipment, prevention of chemical transportation/handling issues, and promotion of white logistics.

NISSHOKU TECHNO FINE CHEMICAL CO., LTD.

| Principal business | Manufacture and sale of (meth)acrylic acid derivatives and photo/electro chemicals |

|---|

In FY2024, as in the previous year, there were injuries without lost workdays involving younger employees. As countermeasures, we have standardized work procedures, enforced the use of personal protective equipment, and reviewed our task risk assessments. Regarding chemical substance risk assessments, we had previously used the simplified Control Banding Method. However, following the revision of the Industrial Safety and Health Act in April 2023, we have established our own method incorporating the more detailed risk assessment approach of the Japan Industrial Safety and Health Association (JISHA), and we have been advancing our risk evaluations accordingly.

In terms of environmental protection, we are working to reduce CO₂ emissions, the volume of total waste, emissions of substances subject to the PRTR Law, and energy consumption. The reduction of CO₂ emissions has been promoted through the full-scale operation of gas boilers introduced in FY2023. We plan to further reduce CO₂ emissions by continuing to replace heavy oil boilers with gas boilers. Additionally, for waste, substances subject to the PRTR Law, and energy consumption, we aim to reduce intensity compared to FY2023 through stable production and improved productivity.

As part of our process safety and disaster prevention initiatives, we also conducted a comprehensive emergency drill in FY2024 with the participation of the Joint Disaster Prevention Center. The drill followed a scenario assuming an earthquake and fire, and we confirmed our cooperation system with the Joint Disaster Prevention Center in the event of a disaster.

TOKYO FINE CHEMICAL CO., LTD.

| Principal business | Manufacture and sale of antiseptics, antifungal agents, disinfectants, brine, stabilizers of vinyl chloride resins, etc. |

|---|

Continuing from the previous fiscal year, we carried out safety activities in FY2024 with the objective of achieving zero occupational injuries. Unfortunately, one occupational injury occurred. In response to the incident in FY2022, we had been conducting more detailed risk assessments by breaking down the task. However, this recent injury was not anticipated in the risk assessment. Along with occupational injuries involving younger employees, unanticipated risks remain an issue, and we will continue to consider preventive measures.

As part of our environmental protection efforts, we have started recovering PET resin powder—previously disposed of in landfills—as recyclable material. We will also continue our efforts to minimize landfill disposal of other waste materials.

In FY2025, we will continue to promote RC initiatives and basic safety activities, aiming for zero occupational injuries and reduced environmental impact.

NIPPOH CHEMICALS CO., LTD.

| Principal business | Manufacture and sale of iodine, iodine compounds, raw materials for pharmaceuticals and pesticides, and natural gas |

|---|

In FY2024, as the final year of our RC Medium-term Plan, we implemented various initiatives to achieve our objectives.

In the area of occupational safety and health, unfortunately, one injury without lost workdays occurred during non-routine work. We are thoroughly investigating the cause and steadily implementing recurrence prevention countermeasures, including replacing equipment with safer alternatives, reviewing work methods, and reinforcing hazard prediction with multiple personnel.

On the other hand, as a countermeasure against occupational injuries caused by chemical exposure—which have been increasing in recent years—we have resumed hands-on training to experience the dangers of liquid exposure using in-house equipment, which had been suspended during the COVID-19 pandemic. Through simulated experiences of chemical contact, we aim to raise employees’ safety awareness.

In terms of environmental protection, we are actively addressing global warming countermeasures. In FY2024, we focused on establishing technology to reduce methane gas emissions from wells that extract iodine and other substances. With this technology in place, we expect to reduce greenhouse gas emissions by approximately 5,400 tons annually by FY2030.

We will continue to promote safer and more environmentally friendly RC activities, driven by the proactive participation of every employee.