Himeji Plant

| Plant Manager | Kazuto Okazaki, Executive Officer |

|---|---|

| Location | 992-1 Aza-Nishioki, Okinohama, Aboshi-ku, Himeji, Hyogo |

| Number of employees | 1,263 (including research center) (As of March 31, 2025) |

| Products | Acrylic acid, acrylates, maleic anhydride, superabsorbent polymers, resin modifiers, electronic information materials, De-NOx catalysts, dioxins decomposition catalysts, and other products |

FY2024 Results of RC Activities

| Occupational safety and health | One injury with lost workdays, four injuries without lost workdays (including contractors) |

|---|---|

| Process safety and disaster prevention | Zero Class A process safety accidents, one Class B process safety accident |

| Environmental protection | Implemented measures for energy conservation amounting to about 4,500 kL/year (crude oil equivalent) |

In terms of occupational safety and health, we have conducted “mask fit tests” to ensure that respiratory protective masks fit snugly on workers’ faces to reduce health risks from exposure to chemical substances. We have also provided guidance on proper wearing instructions.

In process safety and disaster prevention, we have been working on preventing process safety accidents caused by human error under the initiative called “Safety Reform 2025” since the second half of FY2023. Activities such as promoting speaking up, asking questions, watching over others, and holding interdepartmental meetings have contributed to the development of a safety culture where employee helps each other. As a result, process safety accidents decreased in FY2024. Additionally, there have been positive impacts such as reductions in occupational injuries and quality issues. We will continue this initiative in FY2025.

In environmental protection, we have continued material recycling of waste plastics. Over 500 tons of waste plastics were recycled for new uses in FY2024. Additionally, we have been continuing energy conservation activities aimed at contributing to carbon neutrality, achieving energy savings that significantly exceed our targets in recent years.

We will continue to improve our safety capacity and respond flexibly to changes in society to build a manufacturing plant trusted by stakeholders.

Safety II initiative

At the Himeji Plant, we have focused on thoroughly disseminating countermeasures for occupational injuries and issues, enhancing safe work procedures, and revising rules. However, we have not seen sufficient effectiveness in preventing occupational injuries caused by unsafe behaviors of workers. Therefore, we reviewed our safety activities under the guidance of ergonomics experts.

Interviews conducted by the experts revealed that safety rules and basic safety behaviors were not always followed at the production site. Additionally, it was pointed out that each time an issue occurred, new rules were added, making work more difficult, and there was dissatisfaction with the lack of attention to rule violators, leading to decreased motivation. Therefore, we started a Safety II initiative that not only focuses on enforcing rules but also highlights the behaviors of people who can flexibly respond to various situations and disseminates these behaviors horizontally to encourage autonomous judgment and actions among employees.

Specifically, we are promoting activities such as the “compliment activity,” where employees who demonstrate safe behaviors are voted for and recognized, and sharing the behavioral characteristics and thought processes of those who quickly identify and resolve equipment issues as success tips within the plant.

We will continue to improve these initiatives and work towards preventing occupational injuries and issues.

Non-technical skills training

Many occupational injuries are caused by human error, and approximately 80% of these are due to a lack of non-technical skills. Non-technical skills, in contrast to technical skills which involve specialized knowledge and expertise, include human skills such as situational judgment, communication ability, leadership, and teamwork. At the Himeji Plant, we conduct non-technical skills training using a simulated plant to improve the skills of younger employees. Since FY2023, we have expanded these training opportunities to Group companies as well. Participants have expressed a renewed recognition of the necessity of non-technical skills and the importance of communication.

We will continue to enhance the program content and facilities to ensure the steady improvement of the skills of younger employees.

Topic

Participation in “Demand Response” contributes to stabilizing the balance between supply and demand of electricity

“Demand Response (DR)” has been attracting attention as a method of adjusting the supply-demand balance of electric power as the introduction of renewable energy sources, which are unstable in terms of power generation, expands. As one of its social contribution activities, Himeji Plant has concluded a contract with a DR aggregator* and has been participating in DR on an ongoing basis since FY2021. When the supply-demand balance of electric power becomes tight due to extreme heat, severe winter, or bad weather, the plant will contribute to stabilizing the supply-demand balance of electric power by reducing the amount of power received from the power grid based on requests from the DR aggregator, utilizing excess power generation capacity.

*DR aggregator: A business operator that aggregates multiple consumers and adjusts supply and demand

Plant Data

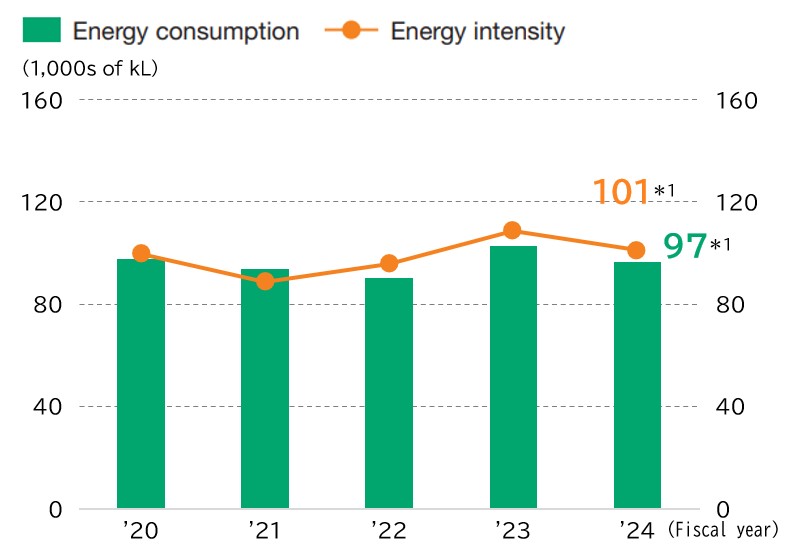

Trends in Energy Consumption and Intensity

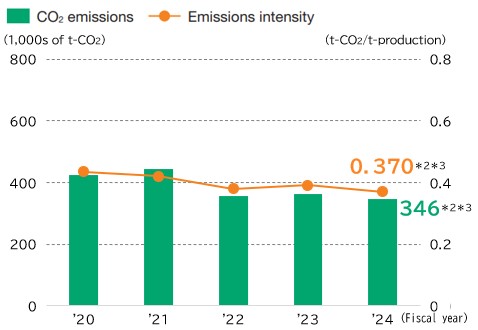

Trends in CO₂ Emissions and Intensity

*3 Due to the revision of the Act on Promotion of Global Warming Countermeasures (Global Warming Countermeasures Act), the calculation method has been revised from the fiscal 2023 results.

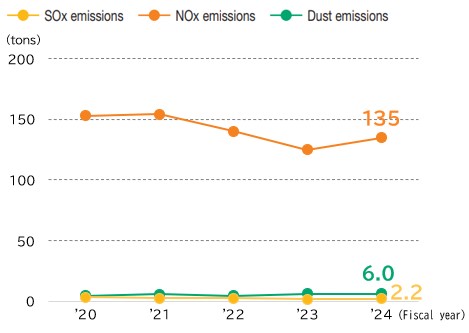

Trends in Emissions of SOx, NOx, and Dust

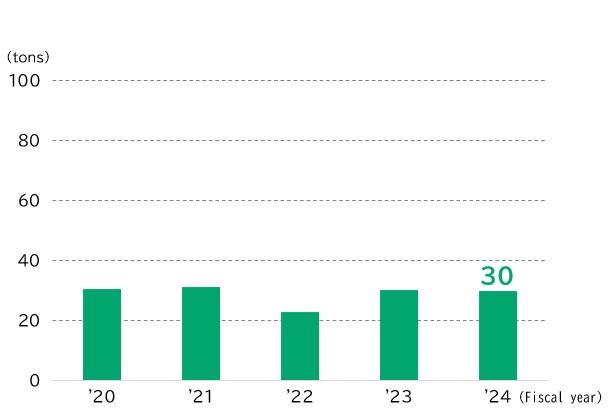

Trend in COD of Wastewater

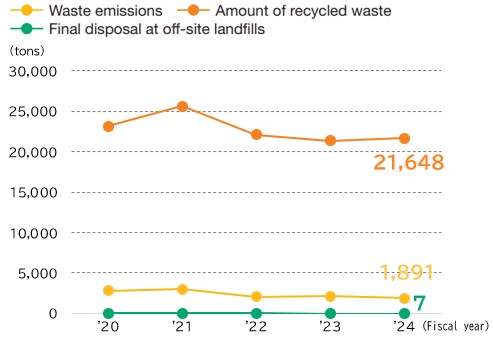

Trends in Amount of Waste, Recycled Waste, and Waste for Final Off-site Landfill Disposal

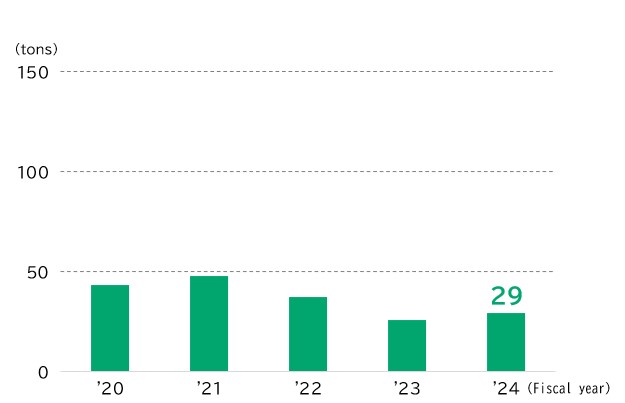

Trend in Emissions of Substances Subject to the PRTR Law