Group Companies outside Japan

SINGAPORE ACRYLIC PTE LTD

| Principal business | Manufacture and sale of acrylic acid |

|---|

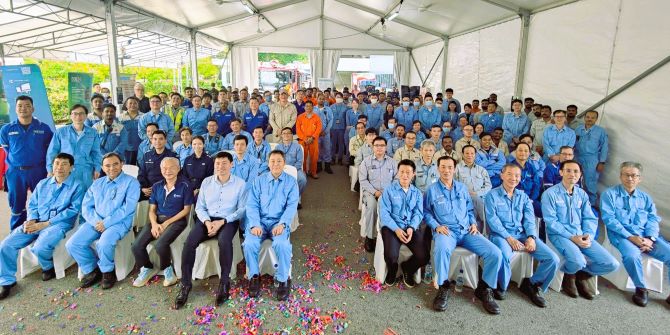

SMAG*1 Safety Promotion Month is an annual event dedicated to emphasizing the importance of safety practices and raising awareness about potential risks in our surroundings. Due to Covid-19 pandemic, HSE*2 safety month promotion activities were held online from 2020 to 2022 which consisted of online safety video messages, online safety bulletin, safety slogan and quiz.

However, in 2023, we were able to return to usual onsite safety promotion activities. The month started off with HSE month opening ceremony, whereby Deputy Director from Ministry of Manpower was invited to give a keynote speech, and followed by participation of activities at safety exhibition and game booths. SMAG employees participated in various onsite safety talks, such as Workplace Fatigue, Workplace Stress, Effect of Shift Work to promote risk awareness of employees and contractors. A safety video and HSE bulletin on the topic “Risk Awareness and Procedure Compliance” were launched. In addition, safety quiz and safety slogan competition were initiated and the winning slogan is “Vigilance Avoids Hazards, Compliance Eliminates Risks Be vigilant, Stay Compliant”. The month ended off with a closing ceremony to distribute prizes to winners from the safety quiz and safety slogan competition.

*1 SMAG:a conglomerate of four Japanese companies in the same complex

*2 HSE:Health, Safety, Environment

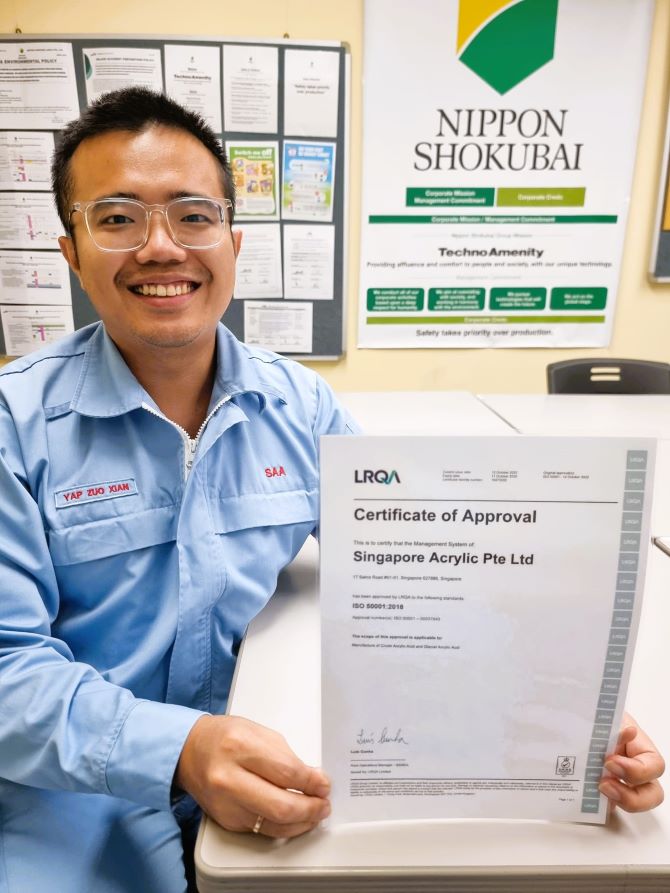

InterviewImplementation of ISO 50001 energy management system

Senior Process Engineer

Process and Engineering Section

SINGAPORE ACRYLIC PTE LTD

In 2022, to meet the National Environment Agency enhanced energy management regulation, we have decided to implement ISO 50001 energy management system to better address our energy management shortcomings and to also improve our overall energy consumption and have successfully obtained the ISO 50001 certification in November 2022. The external consultant conducted ISO 50001 awareness training and internal auditor training course for our employees. Example of objective and target of the energy management system includes optimizing of compressor system. With energy management system in place, we hope to reduce energy consumption and improve energy efficiency for our plant.

NISSHOKU CHEMICAL INDUSTRY (ZHANGJIAGANG) CO., LTD. (China)

| Principal business | Manufacture and sale of superabsorbent polymers |

|---|

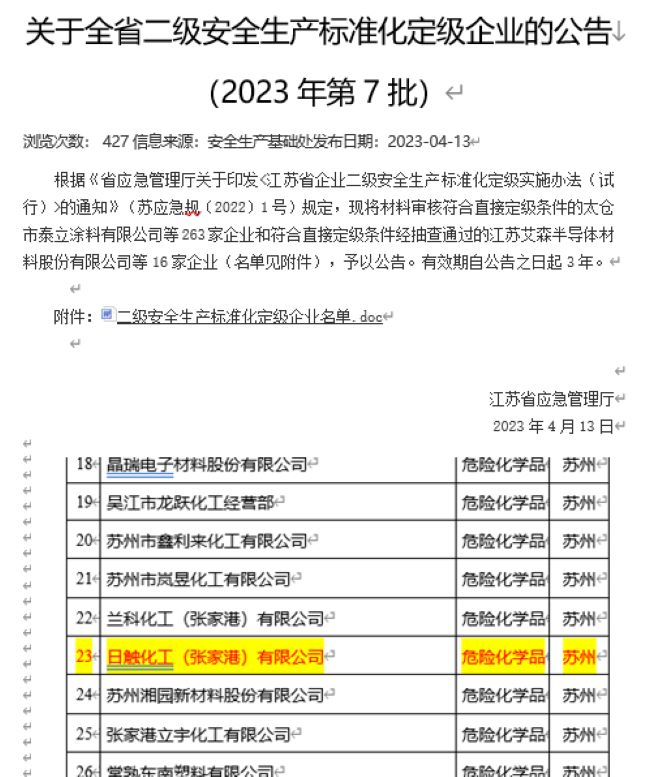

Through the efforts of all departments of the company in 2023, we successfully completed the renewal of the safety production license and obtained a new safety production license, which is valid from January 2024 to January 2027.

In April 2023, the Emergency Management Department of Jiangsu Province issued a notice stating that we meet the classification criteria for Level 2 safety production standardization and is a Level 2 safety production standardization enterprise. The validity period is from April 2023 to April 2026.

We will continue our RC initiatives throughout the Company in the future.

NIPPON SHOKUBAI EUROPE N.V. (Belgium)

| Principal business | Manufacture and sale of acrylic acid and superabsorbent polymers |

|---|

Improving the safety awareness and consequently the safety culture:

The behavior of employees is always a reflection of the company culture as it is the majority of all employees who define the behavior as good or as desired. For that reason, we made it our goal to further improve the overall safety behavior of our employees with the purpose of building a more sustainable safety culture within the coming years.

We will achieve this goal by working on two fronts:

– Firstly, several initiatives started with the involvement of our employees, like the introduction of “the PPE*3 of the month”, like the story of a person involved in a serious accident with the consequence of a permanent disability, like witnessing the behavior of employees during unexpected emergency exercises, like introducing life-saving actions and even the road-safety at our company will be improved using the ideas of our employees.

– Secondly, while employees are getting more vigilant for safety, we will implement a risk based process safety approach using the guidelines, developed by the “Center for Chemical Process Safety”

Working on both fronts, our safety awareness and consequently our safety culture will increase making our company more mature to reduce major accidents and improve process industry performance.

*3 PPE: Personal Protective Equipment

Nippon Shokubai America Industries, Inc.

| Principal business | Manufacture and sale of superabsorbent polymers, polymers for concrete admixture, water soluble polymers, and acrylic emulsions |

|---|

In 2023, We took important steps to bolster our Safety and Environmental Programs at both US based facilities.

The Chattanooga facility had a busy year starting two new production lines. Their emulsion product line, which was decommissioned in 2012, was restarted in April 2023 with a new formulation that allows for a cleaner process that generates less waste. Newly built infrastructure, along with proper planning and strong Safety & Environmental Management Systems allowed for the startup of their new process without incident in June 2023.

At the Houston site, employee involvement was strengthened through its tradition of holding slogan contests each year before large-scale maintenance events. The winning slogan for 2023 was: “Do Your Work With Pride, Put Safety In Every Stride!” This slogan is used throughout the facility to keep this important principle on the minds of all employees during day-to-day operations.

The Houston and Chattanooga facilities obtained ISO 45001, 14001, and 9001 certifications and continue to strive for excellence in achieving their safety and environmental performance goals at both US based facilities.

PT. NIPPON SHOKUBAI INDONESIA

| Principal business | Manufacture and sale of acrylic acid, acrylic esters, and superabsorbent polymers |

|---|

Although in the past we conducted emergency drills during the day, in FY2023, we made plans to conduct night-time drills for all shifts.

In February 2024, we conducted Emergency Phase-1 Drills. The drill started at 7 p.m. with the scenario of fire occurrence, and the shift operation supervisor took command, with the shift operator, security personnel, and paramedics all taking part in the drill.

Although the drill went smoothly, some activities took time due to the darkness as assumed. Measures to address this issue include turning on all lighting, conducting regular inspections, and providing flashlights to allow the site supervisor to easily confirm their instructions.

We will incorporate the measures to address issues in this drill to future drills to improve our emergency response capabilities.

SINO-JAPAN CHEMICAL CO., LTD. (Taiwan)

| Principal business | Manufacture and sale of surfactant and other chemicals |

|---|

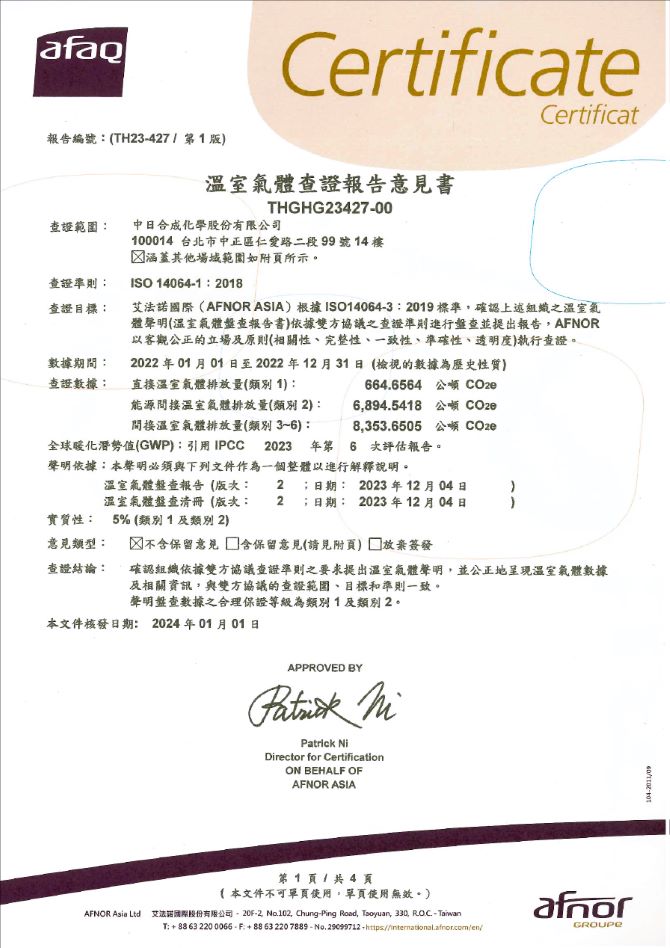

To prevent global warming and climate change that can cause various environmental problems, the Taiwanese government set greenhouse gas emission reduction targets, aiming for a 10% reduction based on 2005 emission levels by 2025, a 24 ±1% reduction by 2030, and net zero emissions by 2050.

In FY2023, we calculated our own greenhouse gas emissions for FY2022 in order to formulate emission reduction targets in line with the government action. As part of the first phase from FY2024 to FY2030, we set an annual reduction target of 3% based on our FY2022 greenhouse gas emissions. For the second phase starting in FY2031, we set an annual reduction target of 4%. With the public announcement of our efforts to reduce greenhouse gas emissions and in an effort to increase our competitiveness by earning the trust of stakeholders, we adopted ISO 14064-1, the international standard for calculating emissions, and had our calculations externally reviewed.

The external review was completed in November 2023, and the review report was received in January 2024.