Kawasaki Plant

| Plant Manager | Koji Takeda, Executive Officer |

|---|---|

| Location | Chidori Plant 14-1 Chidori-cho, Kawasaki-ku, Kawasaki, Kanagawa Ukishima Plant 10-12 Ukishima-cho, Kawasaki-ku, Kawasaki, Kanagawa |

| Number of employees | 363 (As of March 31, 2025) |

| Products | Ethylene oxide, ethylene glycol, ethanolamine, polyethyleneimine, secondary alcohol ethoxylates, polymers for concrete admixture, acrylic acid special ester, and other products |

FY2024 Results of RC Activities

| Occupational safety and health | One injury with lost workdays, three injuries without lost workdays (including contractors) |

|---|---|

| Process safety and disaster prevention | Zero Class A and Class B process safety accidents |

| Environmental protection | Implemented measures for energy conservation amounting to about 3,200 kL/year (crude oil equivalent) |

In terms of occupational safety and health, there were one injury with loss of workdays (fall) and three injuries without loss of workdays (chemical burns, etc.). As countermeasures, we thoroughly implemented hazard prediction before work, re-educated employees on personal protective equipment wear standards and past cases of occupational injuries, and worked to prevent the recurrence of similar issues.

In process safety and disaster prevention, we achieved zero Class A and Class B process safety accidents. Additionally, we are preparing to introduce HAZOP-LOPA as a new method for evaluating process risks.

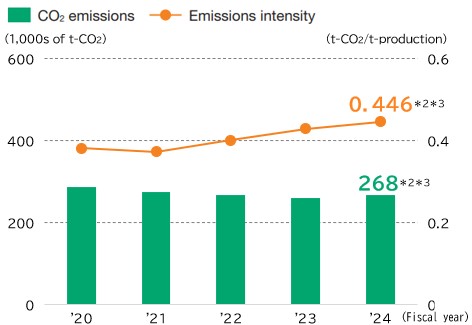

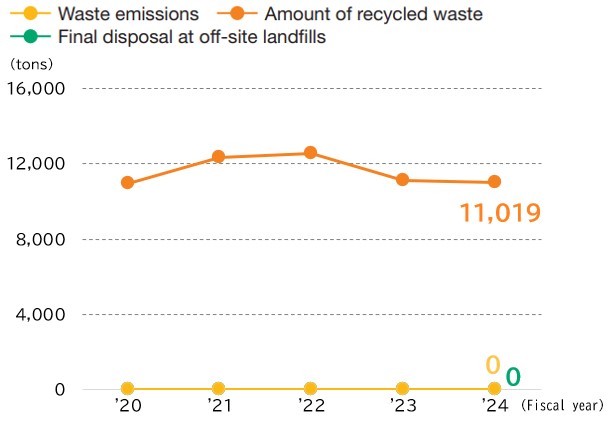

In environmental protection, there was one environmental issue (marine leakage). As countermeasures, we reviewed operation procedures and strengthened equipment to prevent recurrence. We also implemented energy-saving measures, such as introducing an advanced process control system to manufacturing equipment to predict fluctuations in each process and provide simultaneous control. In response to the PRTR Law, we continued efforts to reduce emissions of substances such as boron and ethylene oxide.

We will continue to promote RC activities and aim to build a safer and more reliable manufacturing plant by incorporating cutting-edge technology.

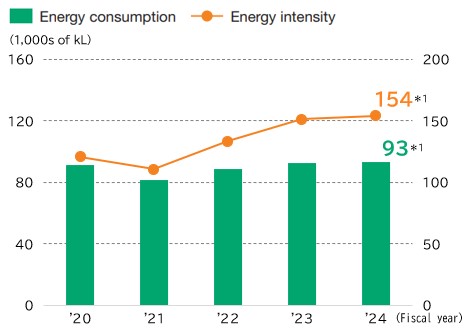

Energy conservation activities at the Chidori Plant

At the Kawasaki Plant, as part of our efforts to improve productivity and energy conservation using DX, we expanded the advanced control system introduced at the Ukishima Plant to the Chidori Plant and optimized the operation patterns of manufacturing equipment according to production volume. As a result, in FY2024, we achieved energy savings equivalent to approximately 3,200 kL of crude oil and reduced CO2 emissions by about 7,500 tons. Additionally, productivity improved, and variable costs were reduced. We will continue to expand the application of the advanced control system and further promote energy conservation.

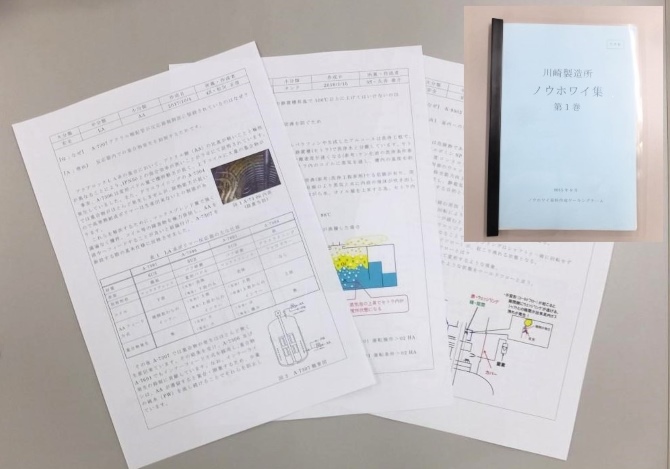

Operator skill transfer through Know-Why Collection

As part of operator training at the Kawasaki Plant, the production section, the technology department, and the training center have collaborated to publish and utilize the “Know-Why Collection.” This document is created to preserve and pass down knowledge about safe operations derived from the experiences of predecessors, the rationale behind work procedures and settings, and the design philosophy at the time the equipment was installed.

In FY2024, Volume 3 of the collection was newly issued. The content is a concise one-sentence answer to the question “Why do we do this?”, such as “It’s because of this,” followed by a detailed explanation of the reason. Each theme is summarized on a single A4-sized page to make the information easy to understand and organize.

This Know-Why Collection is used as educational material in workshops and on-the-job training (OJT), contributing to the skill transfer education for mid-level and younger employees. We will continue to enhance the Know-Why materials in cooperation with related departments to support the improvement of operators’ knowledge.

Plant Data

Trends in Energy Consumption and Intensity

Trends in CO₂ Emissions and Intensity

*3 Due to the revision of the Act on Promotion of Global Warming Countermeasures (Global Warming Countermeasures Act), the calculation method has been revised from the fiscal 2023 results.

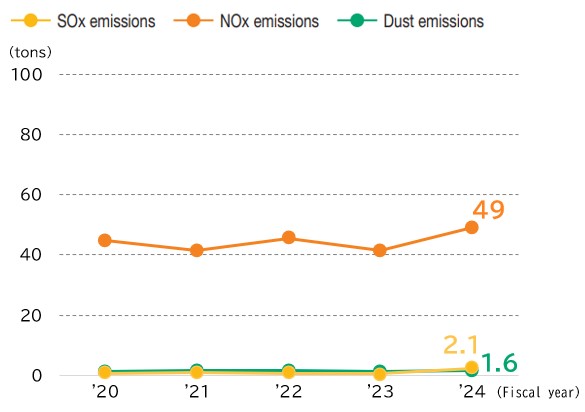

Trends in Emissions of SOx, NOx, and Dust

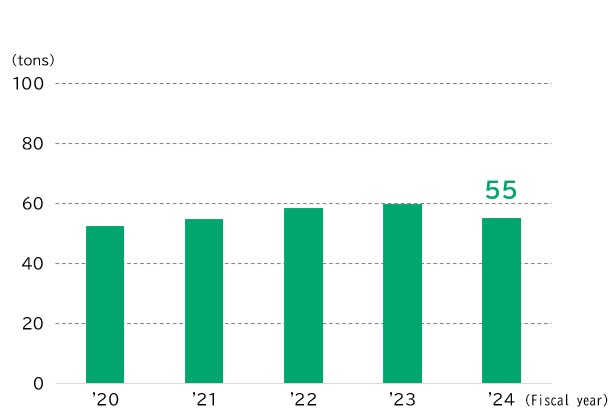

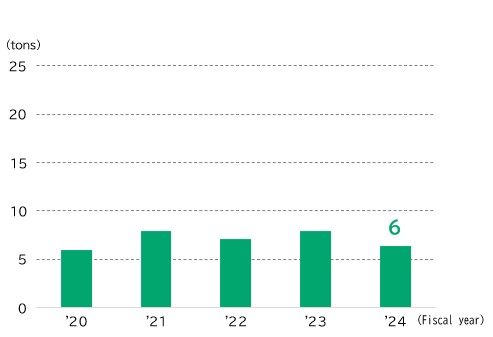

Trend in COD of Wastewater

Trends in Amount of Waste, Recycled Waste, and Waste for Final Off-site Landfill Disposal

Trend in Emissions of Substances Subject to the PRTR Law