Occupational Safety and Health

Aiming for zero occupational injuries, Nippon Shokubai implements occupational safety and health activities to improve working environments, reduce risk factors, and promote the creation of comfortable workplaces.

Occupational Safety and Health Policy

This Policy has been approved by the Sustainability Promotion Committee (formerly the TechnoAmenity Promotion Committee; which is chaired by the President and composed of Inside Directors of the Board, Executive Officers and others appointed by the President).

The Nippon Shokubai Group continues to create comfortable working environments and promote occupational safety and health activities together to prevent occupational injuries and health problems and to ensure safety and health for our employees based on the RC Policy.

Promotion System

Targets and Results

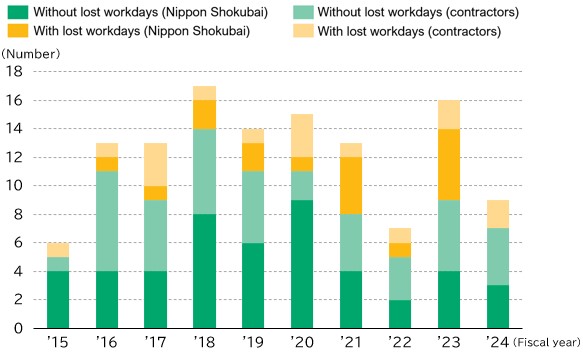

| FY2024 targets | FY2024 results | FY2025 targets |

|---|---|---|

| Zero injuries with lost workdays Zero injuries without lost workdays (including contractors) | Nippon Shokubai Injuries with lost workdays: 0 Injuries without lost workdays: 3 Contractors Injuries with lost workdays: 2 Injuries without lost workdays: 4 | Serious injuries*1: 0 Injuries with lost workdays: 0 Total occupational injury frequency rate*2 ≤ 1.5 (including contractors) |

*1 Serious injuries: Resulting in injuries with 4 or more lost workdays, or a disability class from 1 to 14

*2 Total occupational injury frequency rate: Number of casualties in occupational injuries (injuries with lost workdays (1 day or more) + injuries without lost workdays) per 1 million actual working hours

In the past several years, occupational injuries at the Company have often involved younger employees. Similarly, our affiliates report many injuries among relatively inexperienced workers. We intend to enhance safety training to improve risk awareness among younger and less-experienced employees.

Trends in Total Number of Occupational Injuries

(with Lost Workdays and without Lost Workdays)

Initiatives

Continuously improving Occupational Safety and Health

We work to continuously improve occupational safety and health, mainly through our Occupational Safety and Health Management System (OSHMS). We also engage in hazard prediction (KY activity*1), near miss analysis*2 5S activities*3, and other basic safety activities on a daily basis, and systematically conduct training and drills in an effort to prevent occupational injuries. When occupational injuries occur in the workplace, we explore the causes at the scene, draft countermeasures, and have the Safety and Health Committee evaluate the countermeasures from the perspectives of labor and management to prevent the same or similar injuries from occurring again.

*1 KY activity: An activity involving holding meetings before starting tasks to identify potential hazards (unsafe behaviors and conditions) and undertake countermeasures in an effort to prevent injuries.

*2 Near miss analysis: Reflecting on near misses in everyday operations to identify why they occurred and how they could have been avoided, and undertaking safety measures in terms of both facilities and behavior.

*3 5S activities: Promoting and practicing the 5S: sort, set in order, shine, standardize, and sustain.

Prevention of occupational injuries

We work to reduce and eliminate the risks of tasks and substances we work with, not only for routine work but also for new and non-routine work, by assessing them based on our occupational safety and health management system.

Basic safety initiatives

We recognize the importance of daily safety activities in preventing occupational injuries. Accordingly, we devote energy to KY activities preceding tasks, documenting near misses, and implementing 5S activities in the workplace. We aim to improve daily safety activities by regularly conducting KY training and seminars to maintain and improve risk awareness. Another effort aiming to prevent occupational injuries is posting posters and conducting training to thoroughly inform employees and ensure the rigorous implementation of the three basic safety behaviors: (1) Think before you act; (2) Pointing and calling; and (3) Hold the handrail when stepping on stairs.

Hands-on training sessions

Aiming to improve employees’ sensitivity and ability to predict potential risks in the workplace, we provide various hands-on training programs.

In FY2024, one such program focused on pinch injuries and injuries from being caught in machinery.

Health-related accommodations for retirees from the Company

Although we have never manufactured asbestos products in our history, some of the insulation materials and sealants we used contained asbestos. Therefore, we respond to health-related consultations from retirees from the Company and set up medical examinations for all who desire them. For more information, please visit our website.

Topic

Creating a workplace where everyone can work comfortably

The General Affairs Department at the Himeji Plant is working to create an environment where everyone can work comfortably with the D&I*1 Promotion Team. As part of this effort, in FY2024, we conducted a ‘Women’s Health Seminar’ focusing on health issues specific to women, targeting all employees at the Himeji Plant.

Since FY2020, female employees have been assigned to the manufacturing site. To support these female employees and their supervisors, we have been conducting ‘Women’s Health Seminars’. Through this initiative, we found that the manufacturing site, which had previously been a workplace exclusively for men, was perceived as a difficult environment for women to work in. Particularly, sensitive issues such as menstrual pain and PMS*2 (Premenstrual Syndrome) are difficult for women to discuss with their supervisors and colleagues. When judgment is impaired due to physical discomfort caused by menstruation, it can lead to occupational injuries or process safety accidents. Additionally, working under strain can pose health risks.

To foster understanding and interest in these difficulties, we decided to expand the scale of the seminar. The seminar was conducted in two sessions: the first session aimed at ‘Improving literacy on women’s health issues’ for all employees, and the second session focused on ‘Creating a healthy workplace’ for employees involved in workplace improvement. We invited staff from Japanese Red Cross Society Himeji Hospital as lecturers to provide specialized knowledge.

As a result, the seminar received positive feedback in the questionnaire, such as “I learned a lot of new things that I want to apply to future workplace improvements” and “I was glad that they conveyed what male employees should know.”

We will continue to listen to the voices of our employees and aim to create a safe and secure plant.

General Affairs Department, Himeji Plant

*1 D&I (Diversity and Inclusion): Creating a workplace environment where people with diverse backgrounds are respected and treated equally.

*2 PMS (Premenstrual Syndrome): Physical and mental discomfort that appears 3 to 10 days before menstruation.